Automobile automatic braking mechanism using vacuum booster and controlling method thereof

A vacuum booster and automatic braking technology, which is applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve the problems of potential safety hazards in automobiles, slow pressurization of electronic stability control systems, large vehicle modifications, etc., to achieve braking Good effect, rapid braking, small structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

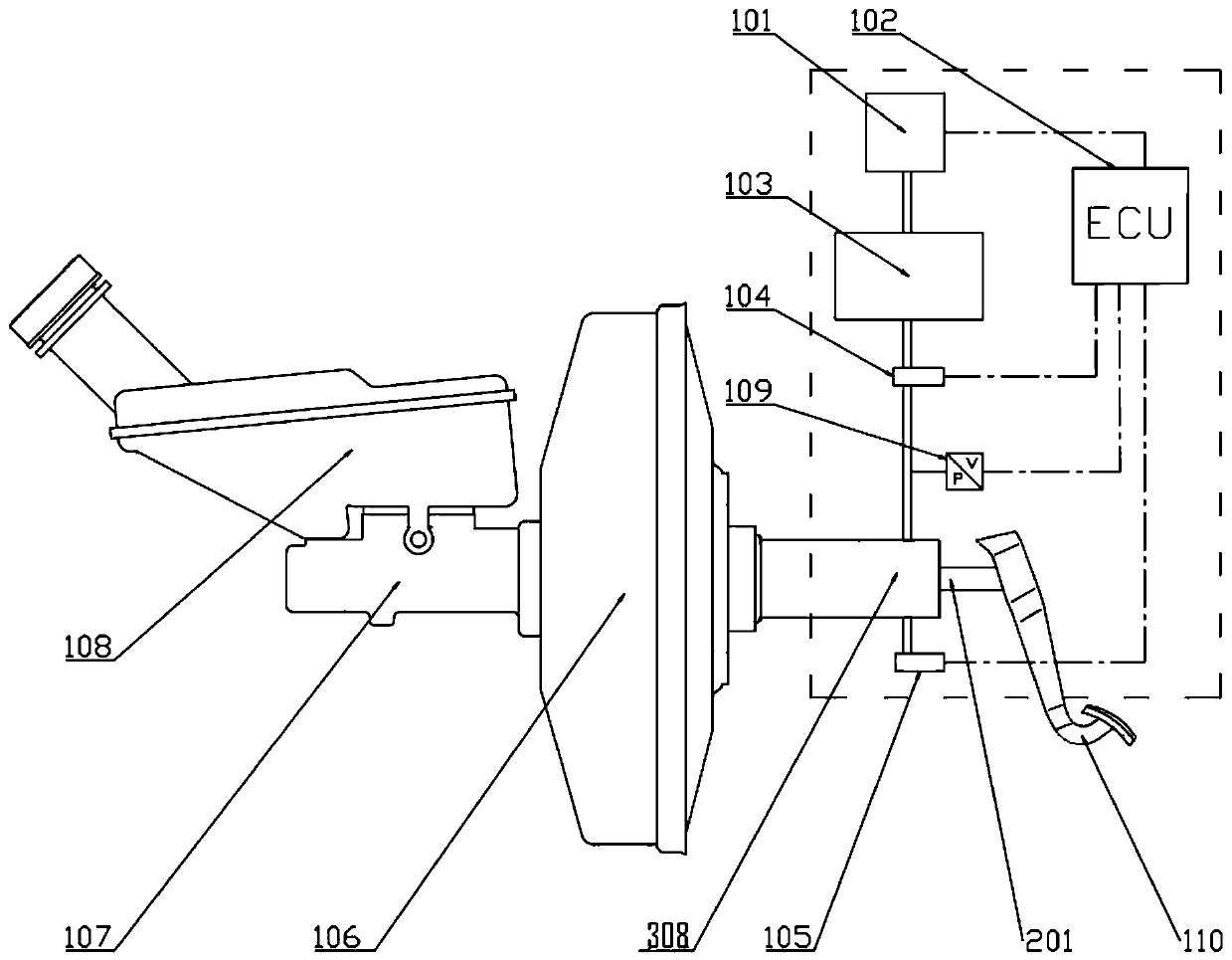

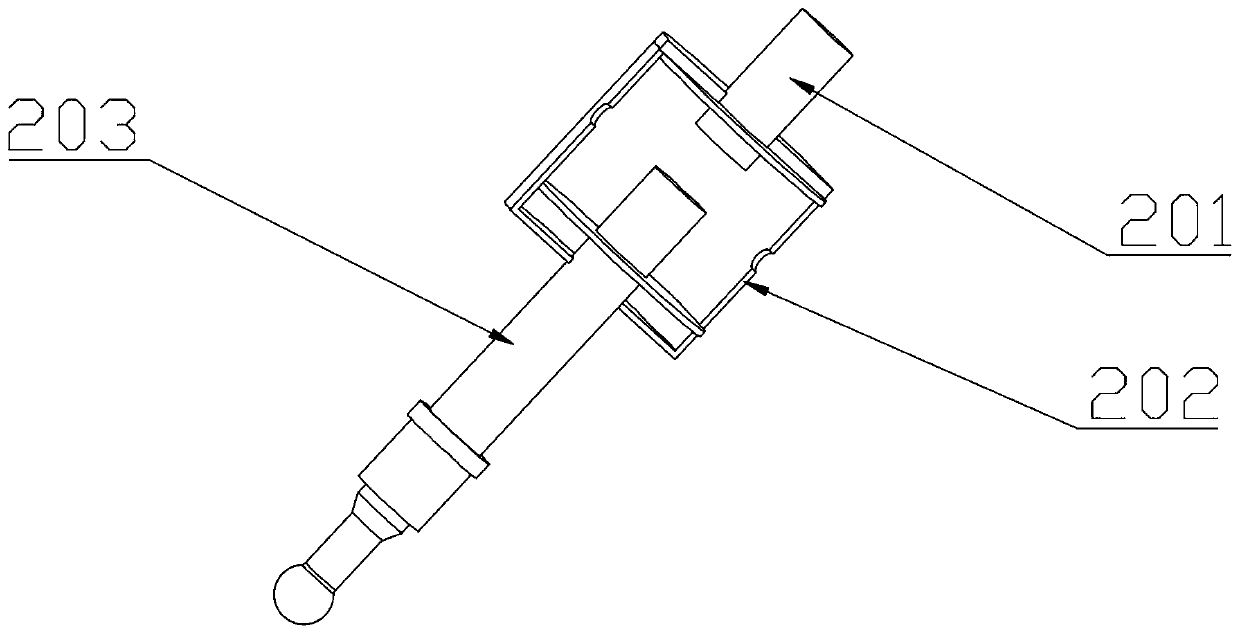

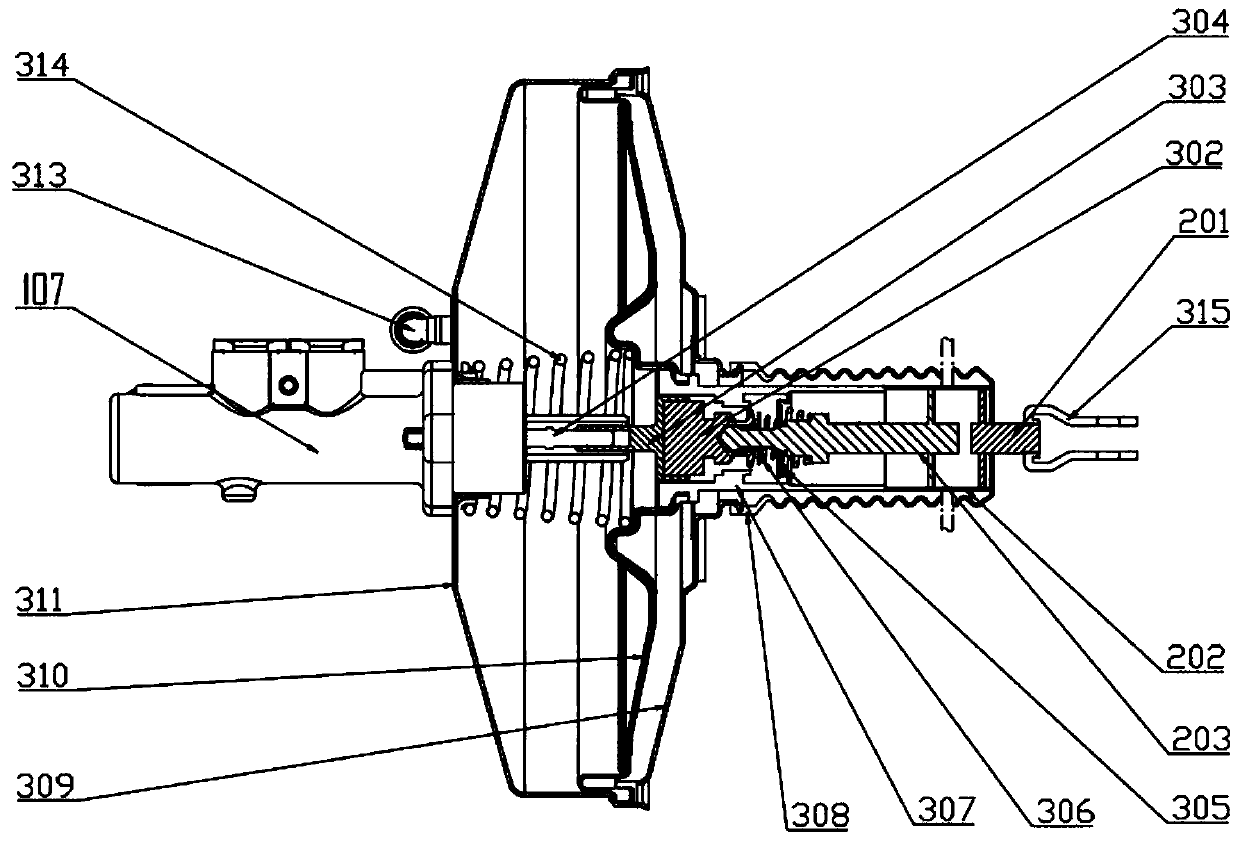

[0059] Such as Figure 1-5 As shown, the present invention provides an automatic braking mechanism utilizing a vacuum booster, including: a front housing 311, a rear housing 309, a master cylinder push rod 304, a spring diaphragm 310, a return spring 314, a push rod mechanism, a spring Mechanism, rear push rod 202, front push rod 201, intake valve 104, exhaust valve 105, automatic braking control unit 102.

[0060] The housing 106 of the vacuum booster includes a front housing 311 and a rear housing 309. The front housing 311 and the rear housing 309 are detachably connected. On the front housing 311, located at one end of the front housing, a vacuum tube 313 is connected. , The front housing 311 is connected to a vacuum pump through a vacuum tube to provide a vacuum for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com