In-series disc spring large deformation energy consumption beam column node

A beam-column joint, large deformation technology, applied in building components, building types, earthquake resistance, etc., can solve the problems of hysteretic performance decline, large deformation energy-consuming beam-column joints, fatigue failure series disc springs, etc., to improve the low cycle Fatigue performance, increased self-reset capability, less structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

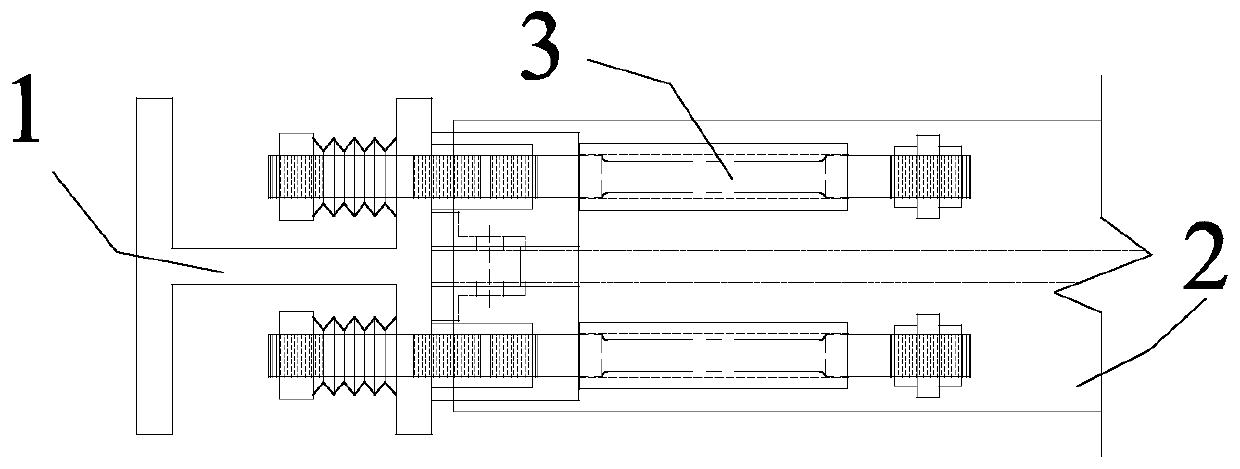

[0021] like Figure 1~2 , the large-deformation energy-dissipating beam-column joints of disc springs in series include fabricated column 1, fabricated beam 2 and disc spring combined damper 3, the surface of fabricated column 1 is fixed with flange plate 11, and the surface of fabricated beam 2 is fixed with plate 21. The fabricated column 1 is a steel column, and the fabricated beam 2 is a steel beam.

[0022] like Figure 3-4 , the energy-dissipating rod 31 of the disc spring combined damper 3 passes through the outer sleeve 34, with threads at both ends, one end is fixed on the fixed plate 21 of the assembled beam 2, and the other end is connected with the internal thread sleeve 33; the guide rod The two ends of 35 are threaded, after passing through the disc spring group 32 and the flange plate 11 of the assembled column 1 to reserve the channel, one end is connected with the internal thread sleeve 33, and the nut 36 is screwed on one end to connect the disc spring grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com