Device capable of removing surface material residues on surface of new material panel

A technology for surface materials and new materials, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of low degree of automation, cumbersome operation, low slag removal efficiency, etc., and achieves manual labor intensity. Small, to meet the needs of processing, to ensure the effect of the slag removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

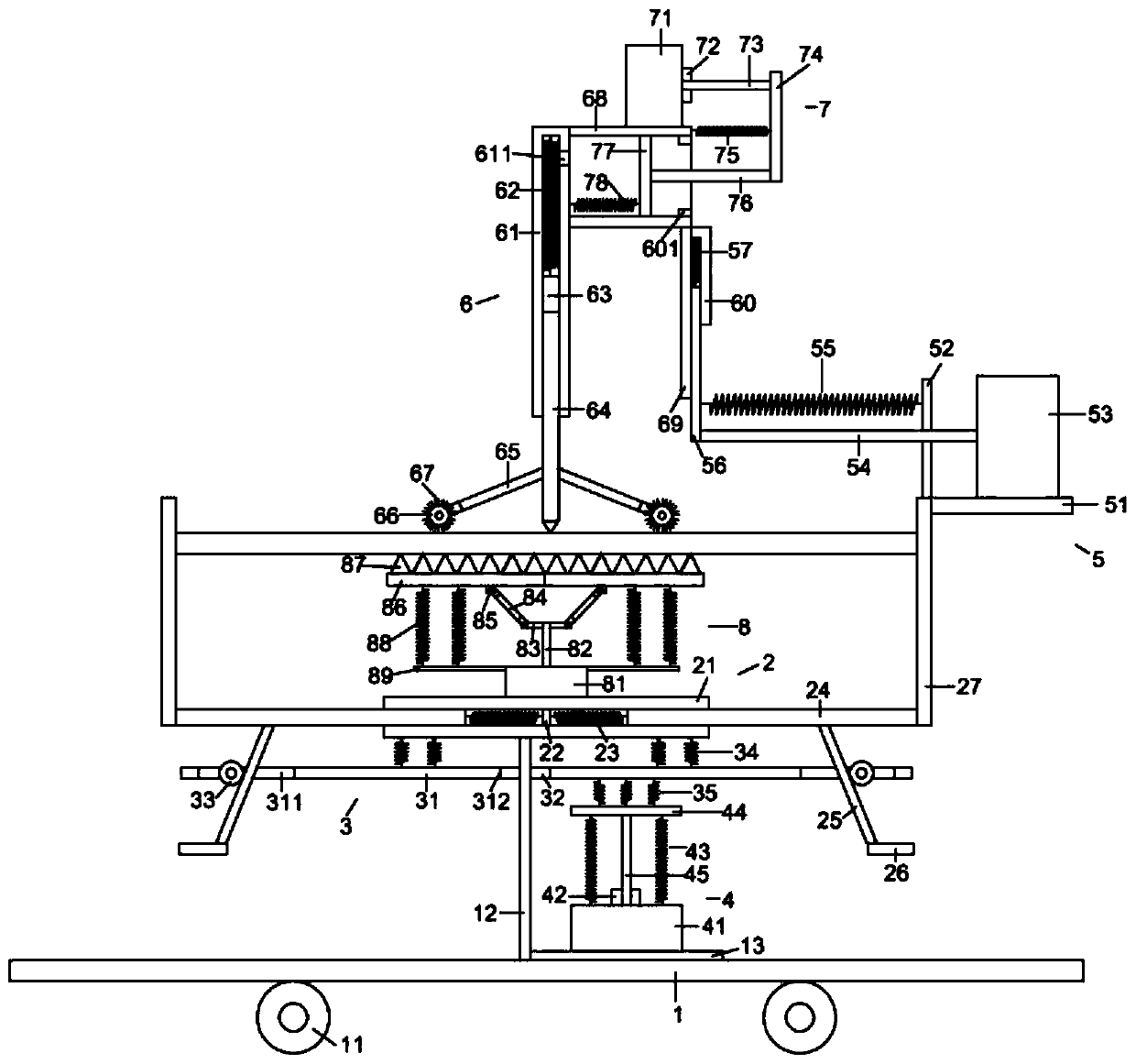

[0009] A clear and complete description will be made below in conjunction with the accompanying drawings to the device of the present invention that can remove the slag on the surface of the new material plate.

[0010] like figure 1 As shown, the present invention can remove the slag on the surface of the new material plate, including a bottom plate 1, a clamping device 2 positioned above the bottom plate 1, an upgrade plate device 3 arranged on the clamping device 2, and an upgrade board device 3 arranged on the bottom plate. The electric cylinder device 4 on 1, the driving device 5 arranged on the clamping device 2, the first scraping device 6 arranged on the driving device 5, the first scraping device 6 arranged on the The piston device 7 and the second scraping device 8 arranged on the clamping device 2 .

[0011] like figure 1 As shown, the base plate 1 is a cuboid, and the base plate 1 is provided with several universal wheels 11 below it, a first support rod 12 above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com