Preparation method of highly active cuprous chloride catalyst for organosilicon monomer synthesis

A cuprous chloride and organosilicon technology, applied in physical/chemical process catalysts, organic chemistry, chemical instruments and methods, etc., can solve the problems of cumbersome operation process and high energy consumption, and achieve improved economic benefits and low energy consumption. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

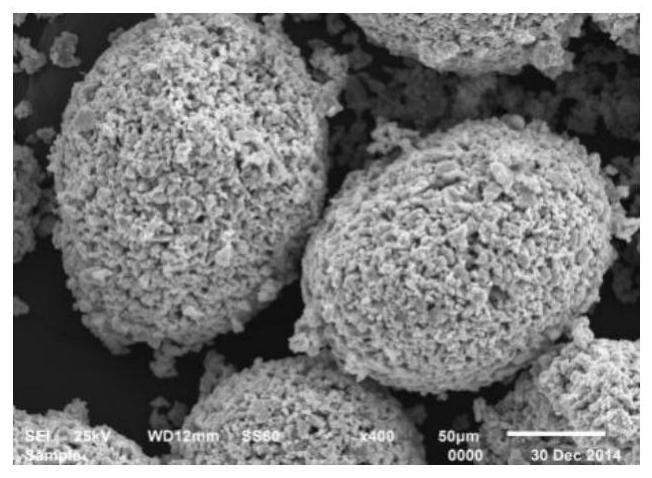

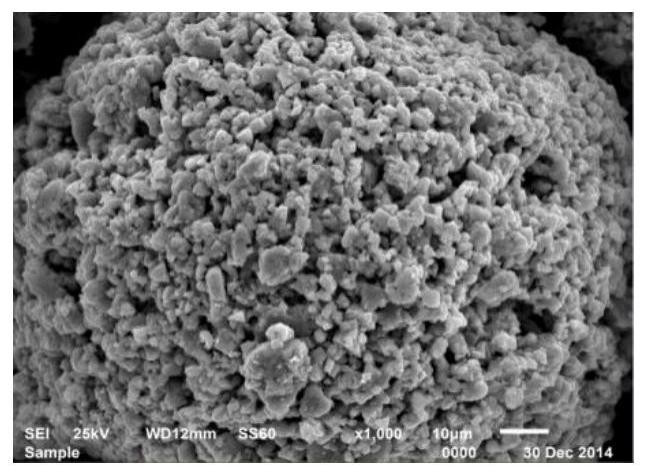

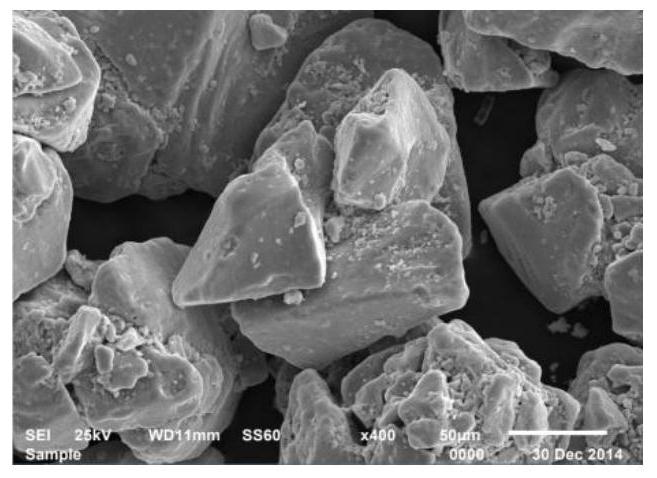

[0019] The present invention is used for the preparation method of the highly active cuprous chloride catalyst of organosilicon monomer synthesis, comprises the following steps:

[0020] Step 1, using ethanol as the solvent and cuprous chloride raw powder with a particle size of 20-30 μm as the solute, mixing the two to make the solid content 60%;

[0021] Step 2, adding binder polyethylene glycol to the solution obtained in step 1, and performing wet ball milling for 4 hours;

[0022] Step 3, sieving the slurry obtained after ball milling in step 2 to obtain a suspension slurry with a solid content of 60%, so that the average particle size of the cuprous chloride particles reaches 5-6 μm viscous slurry;

[0023] Step 4. Under stirring conditions, add a dispersant polyoxyethylene ether to the slurry obtained in step 3 to make the slurry a homogeneous suspension, and the amount of the dispersant is 0.5 to 1% of the total mass of the slurry;

[0024] Step 5. After sieving the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com