Laser cutting head comprosing a body made of two parts, being linked together by a flexible member

A technology of laser cutting head and body, which is applied in the direction of laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

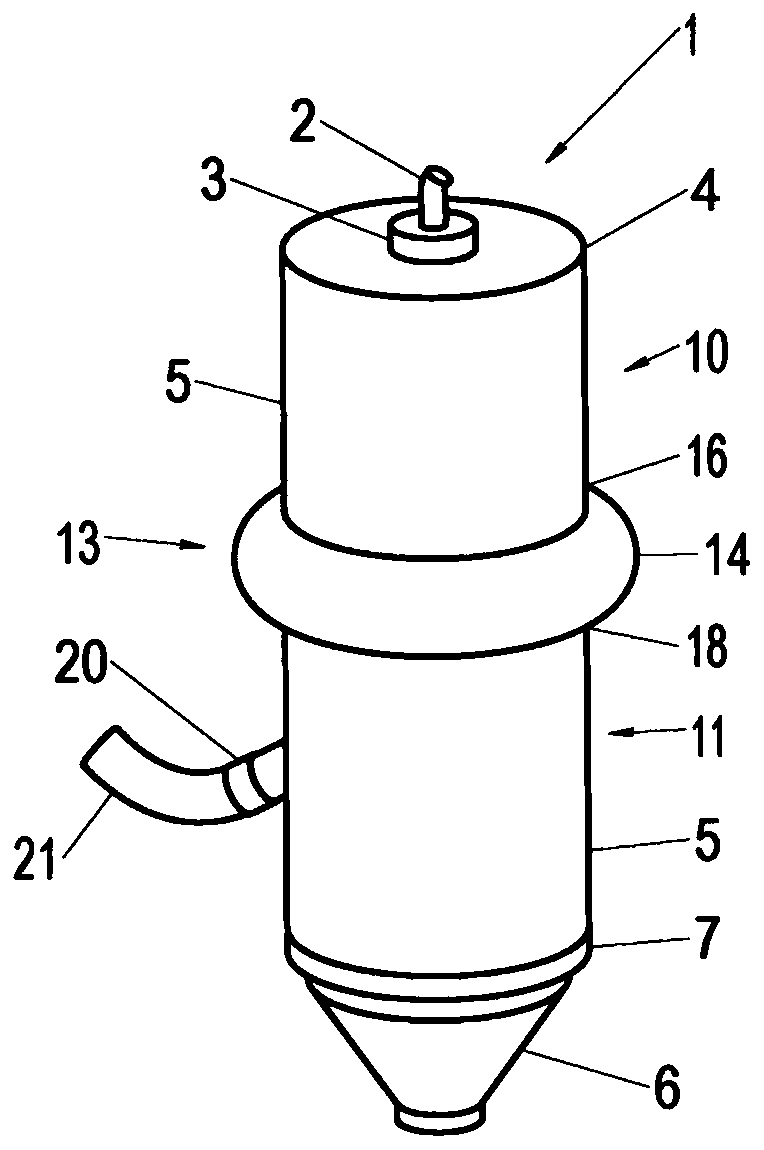

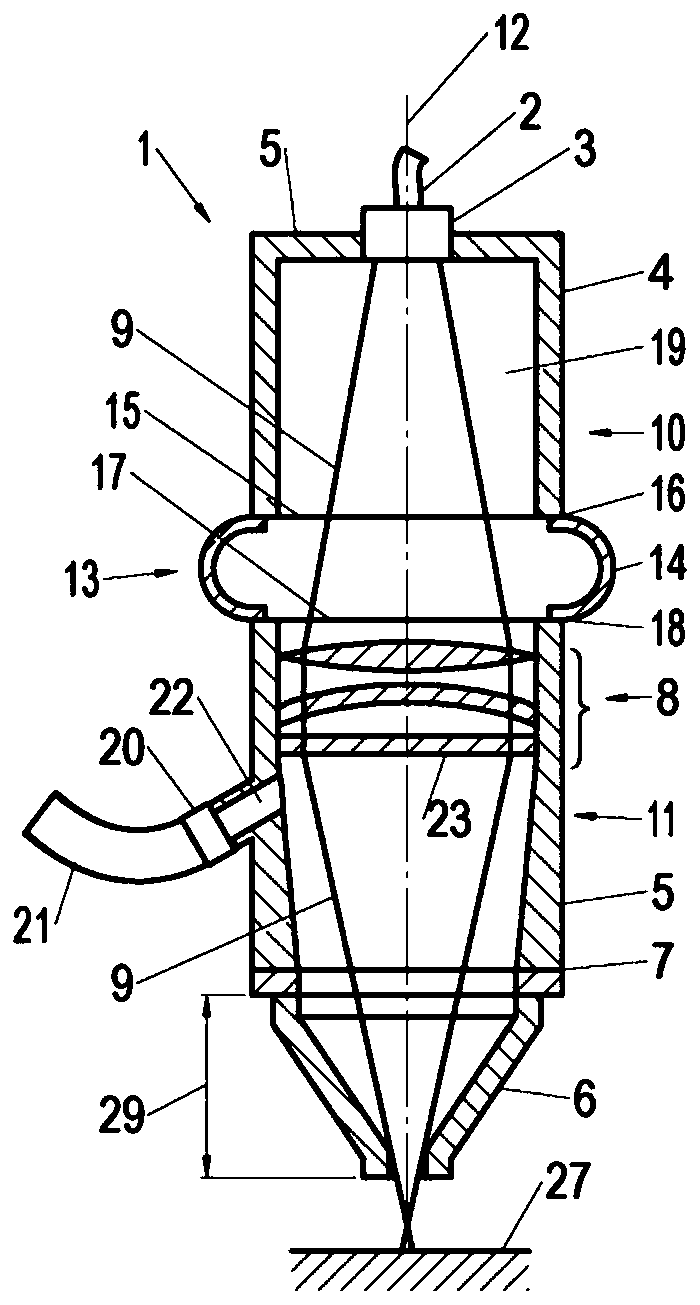

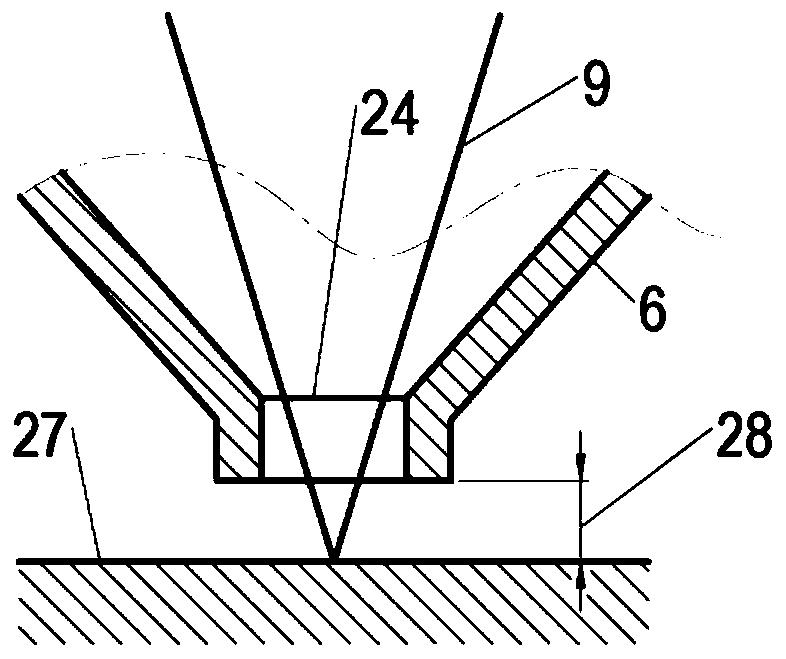

[0054] figure 1 and figure 2 Shown respectively are a perspective view and a cross-sectional view of a laser cutting head 1 comprising: a laser light source 3 connected to an optical fiber 2 and positioned at a first end 4 of a body 5; a nozzle 6, the nozzle 6 Located at the other end 7 of the body 5; the optical system 8, which is located inside the body 5, between the laser light source 3 and the nozzle 6, so that during operation the laser beam 9 passes from the laser light source 3 through the optical system 8 and then through nozzle6.

[0055] The body 2 comprises: a first part 10 of the body 5 integrated with the laser light source 3 and a second part 11 of the body 5 integrated with the optical system 8 and the nozzle 6 . The first part 10 of the body 5 is slidable relative to the second part 11 of the body 5 along and through the optical axis 12 of the head 1 so as to provide a second position of the first part (10) of the body (5) relative to the body (5). The ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com