Fire blast-electromagnetic complex drive jumping mechanism

An electromagnetic composite and detonation technology, which is applied in the direction of electric components, manipulators, electrical components, etc., can solve the problems of difficult control of detonation linear drives and the inability to achieve continuous drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

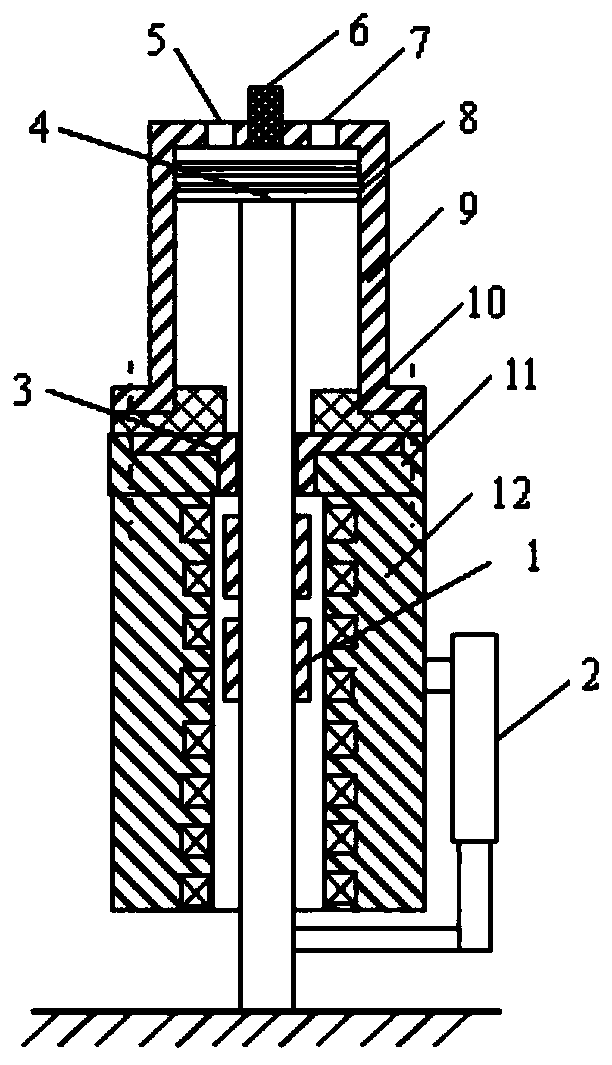

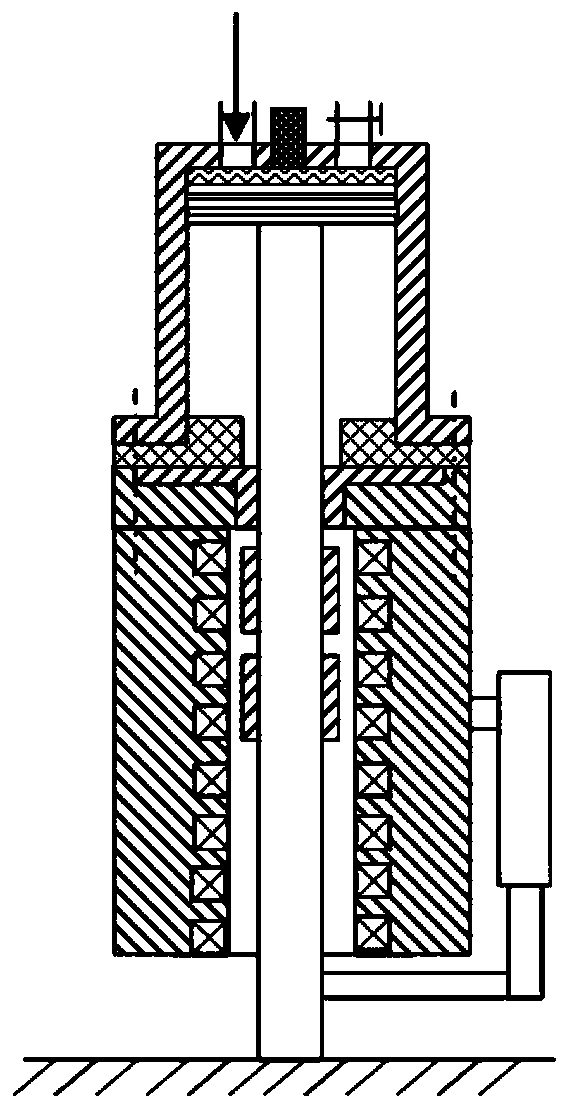

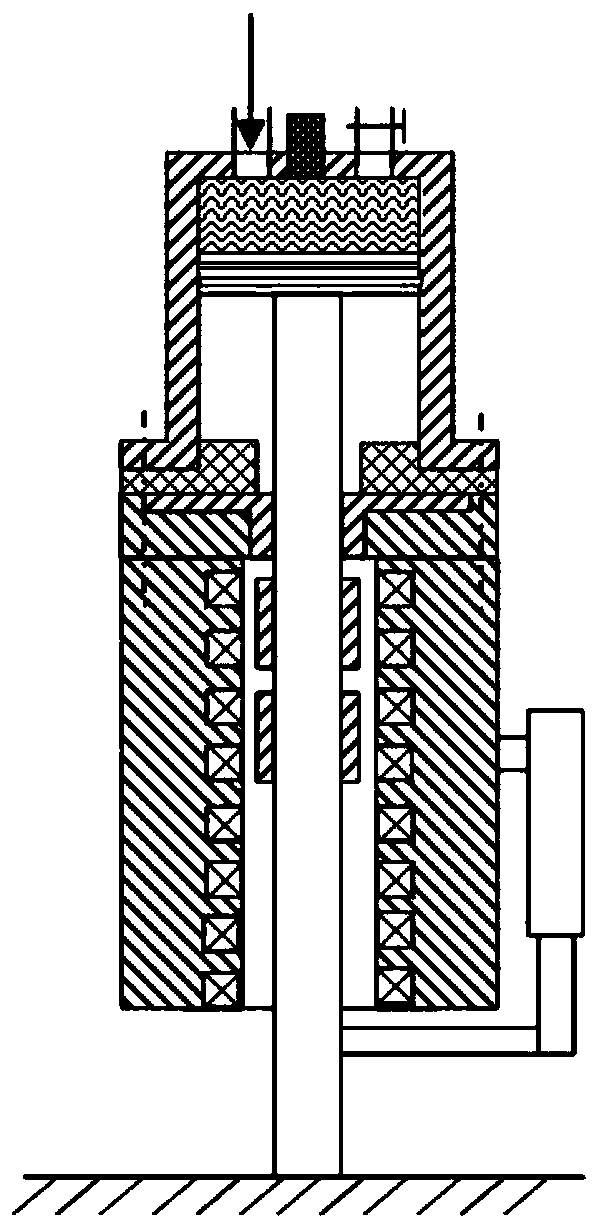

[0027] In order to make the content of the present invention more obvious and understandable, the following in conjunction with the attached Figure 1-5 and specific implementation methods for further description.

[0028] Such as figure 1 As shown, the deflagration-electromagnetic composite drive bounce mechanism of the present invention includes a cylinder-piston assembly and a linear motor. In this embodiment, the linear motor is a purchased part, and the structure of the linear motor mainly includes three parts: a stator, a mover and a guide rail for linear motion. In order to ensure a good electromagnetic field coupling between the stator and the mover within the stroke range, the core lengths of the stator and the mover are different. The stator of the linear motor is stationary during operation, and the stator is fixedly installed on the casing, and its main function is to generate a rotating magnetic field. The mover of the linear motor moves back and forth. The mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com