Oil sludge prevention and real-time treatment system

A technology for real-time treatment of sludge and sludge, applied in the petroleum field, can solve problems such as difficult processing, decreased air flotation efficiency, and high oil content in sludge, and achieves the effects of convenient operation and maintenance, low equipment investment cost, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

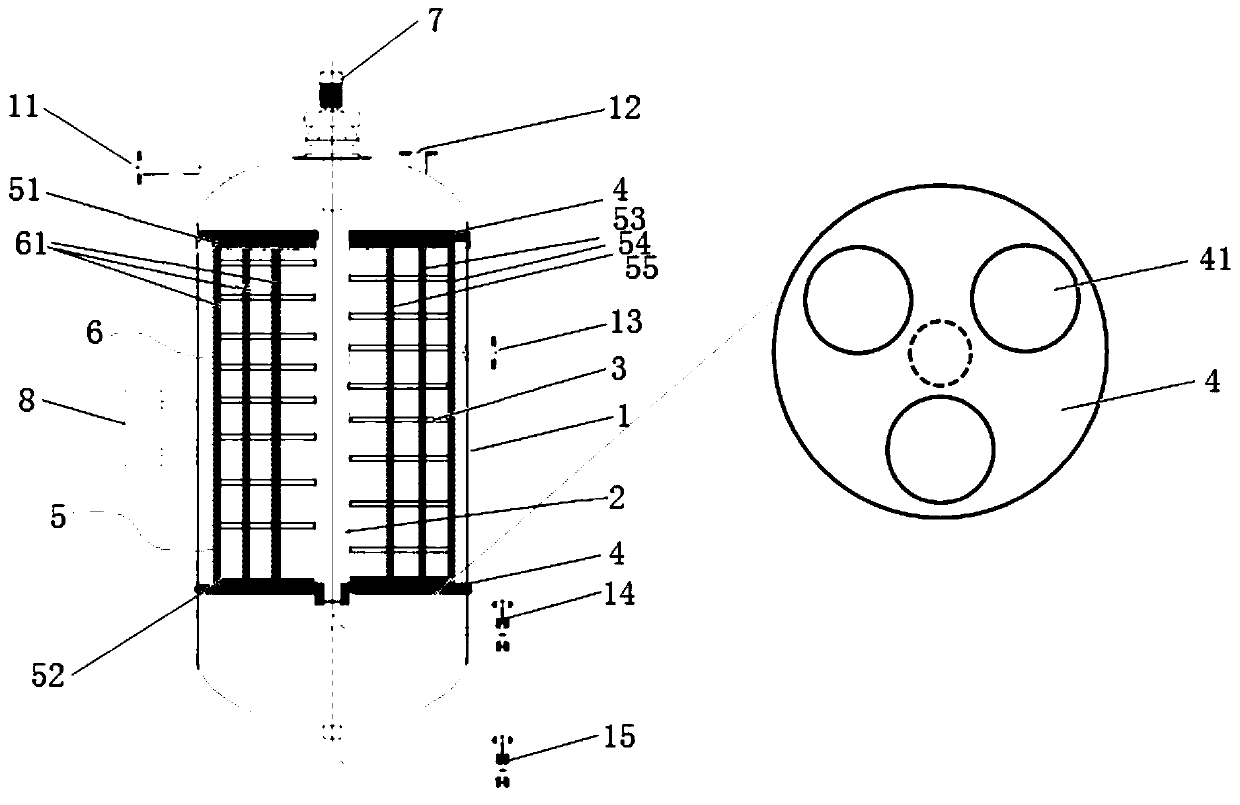

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention. In the description of the present invention, it should be understood that the terms "first", "second" and so on are only used for the purpose of description, and should not be understood as indicating or implying relative importance.

[0019] Such as figure 1 As shown, the sewage sludge prevention and real-time treatment system provided by the present invention includes a filter tank body 1, a first sewage pipe 2, a second sewage pipe 3, a cover plate 4, a filter device 5, a scraping device 6, an explosion-proof motor 7 and Explosion-proof electric control cabinet 8, wherein, each second sewage discharge pipe 3 is formed by two semi-circular annular plates arranged in pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com