Single-rail needle grinding machine

A needle grinding machine and single-track technology, which is applied in the direction of grinding frame, grinding machine parts, machine tools suitable for grinding the edge of workpieces, etc. The machine is bulky and other problems, so as to save manpower, improve the grinding quality and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

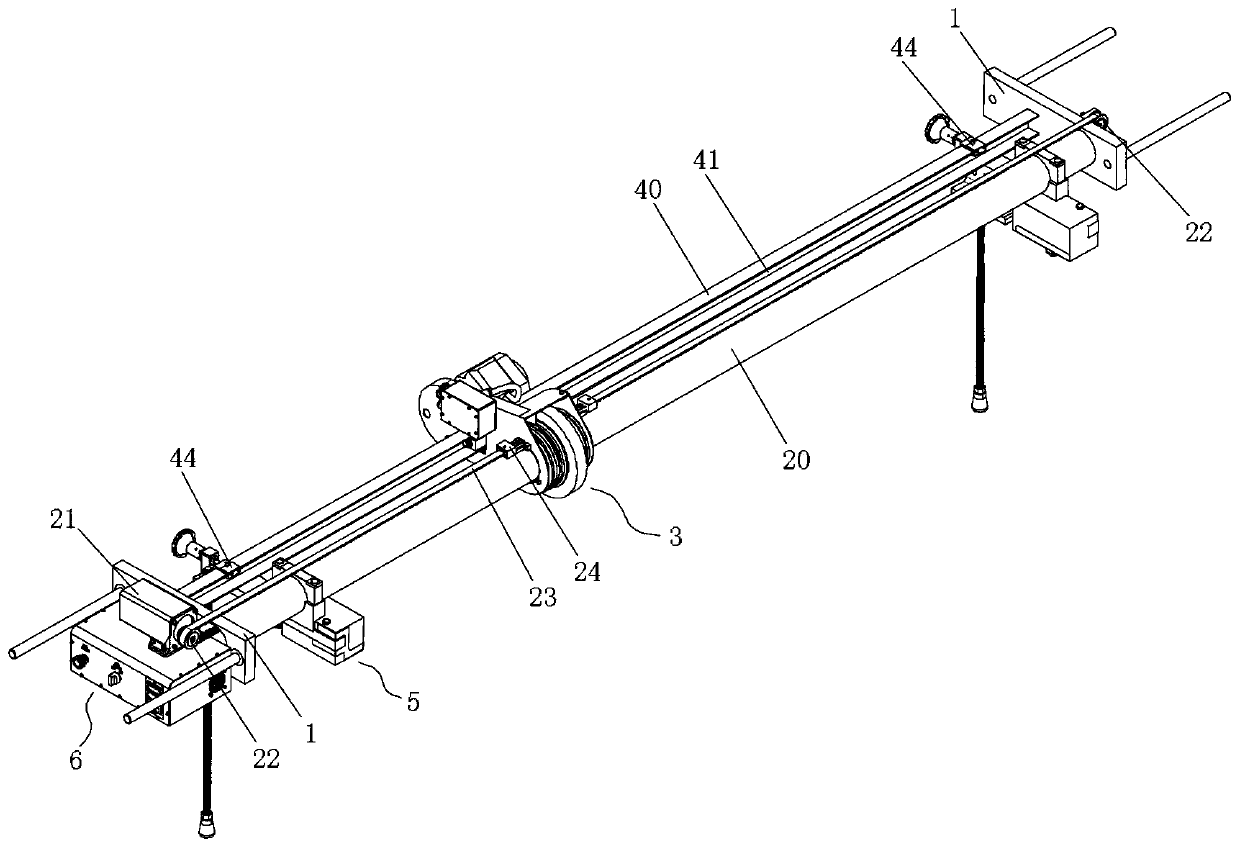

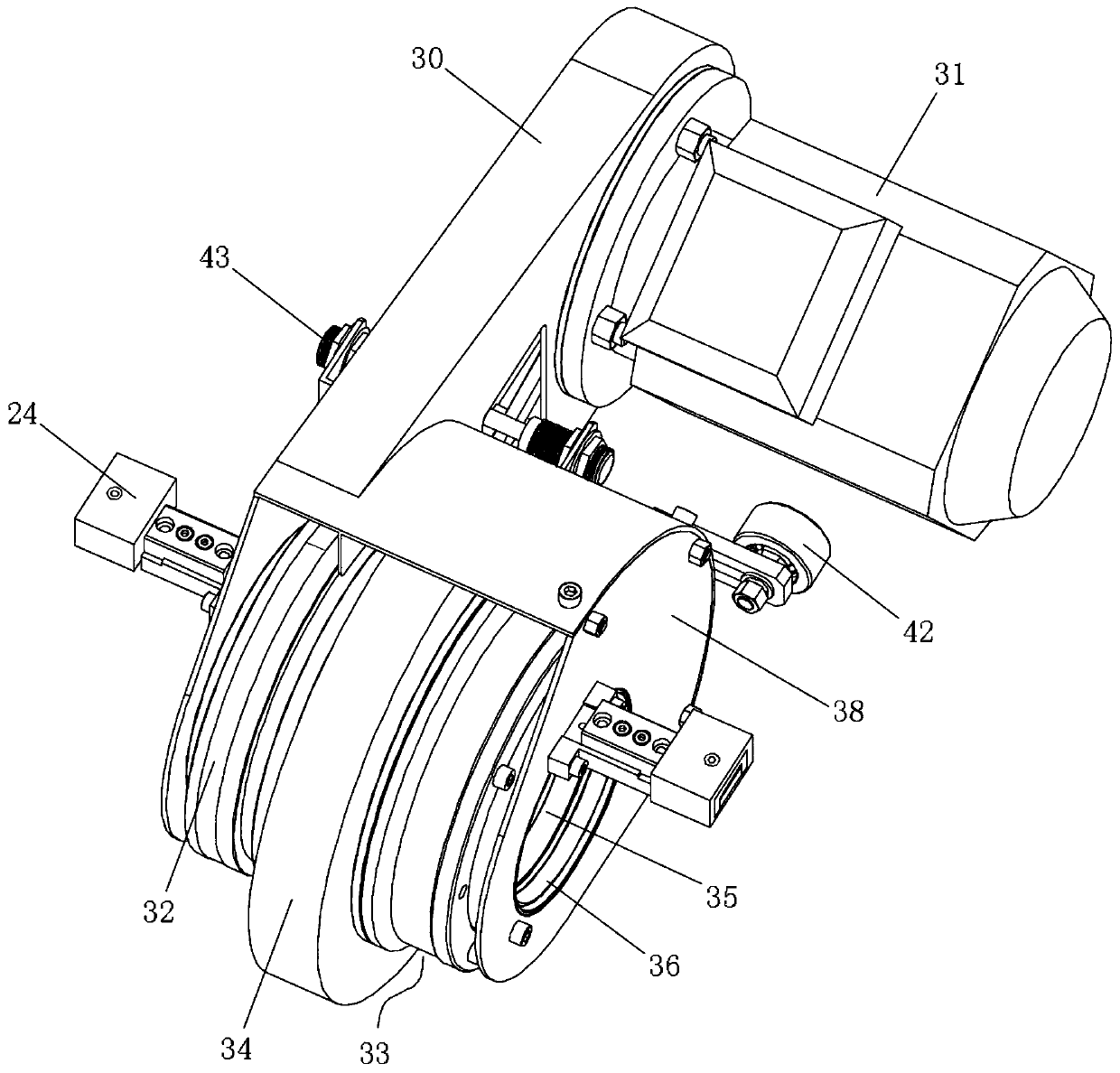

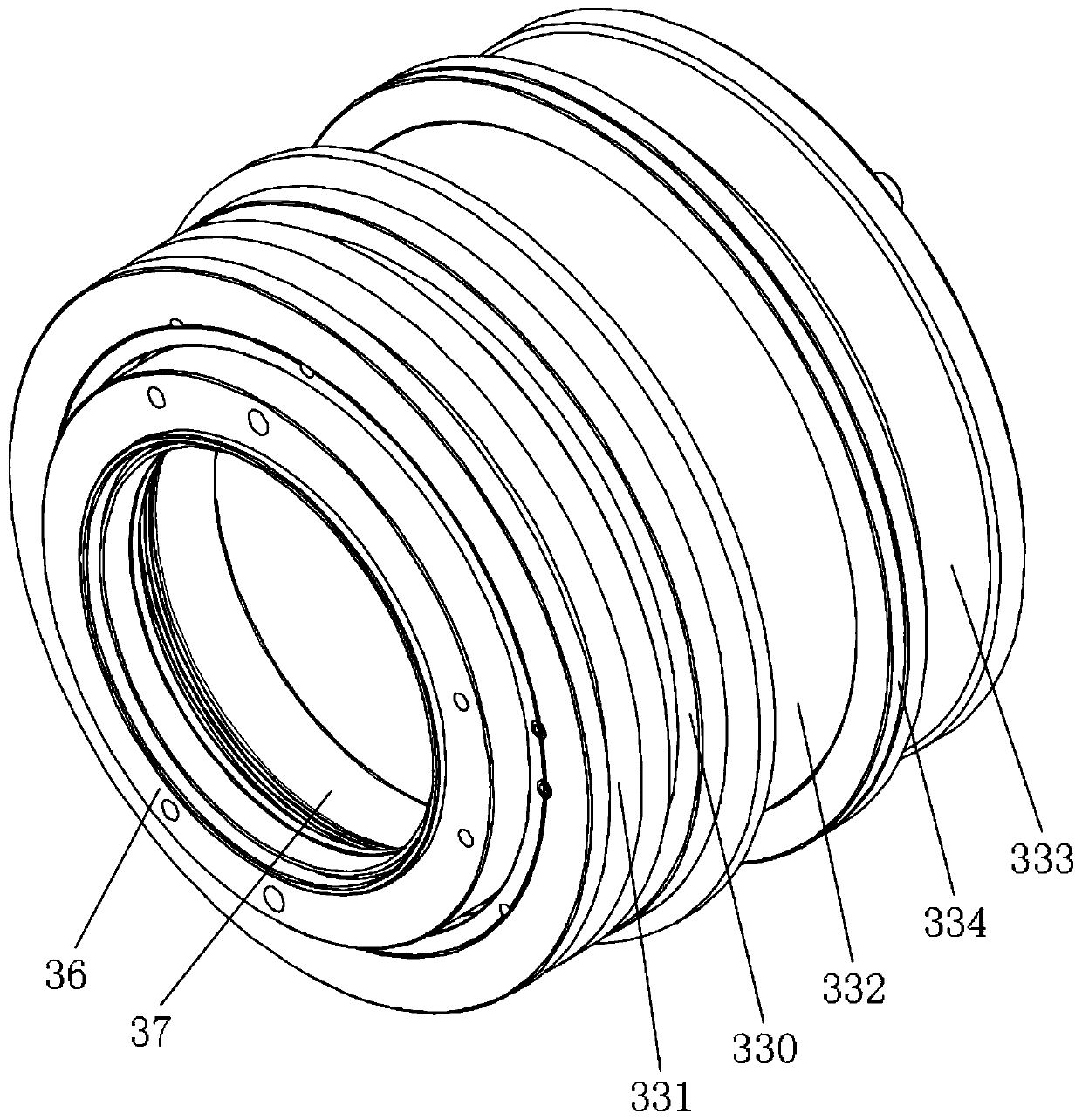

[0034] refer to Figure 1 to Figure 6 As shown, the present invention discloses a single-track needle grinding machine, which includes a frame 1, a displacement mechanism, a grinding head mechanism 3, an auxiliary mechanism, a feed adjustment mechanism 5 and a control box 6.

[0035] Shift mechanism:

[0036] The displacement mechanism above includes a guide rail 20 , a displacement driving source 21 , a displacement driving pulley 22 , a displacement driving belt 23 and a clamping member 24 .

[0037] Both the guide rail 20 and the displacement driving source 21 are arranged on the frame 1 . The central axes of the guide rail 20 and the displacement driving source 21 are perpendicular to each other.

[0038] There are two shift drive pulleys 22 described above. One of the displacement driving pulleys 22 is arranged on the free end of the displacement driving source 21 , and the other displacement driving pulley 22 is arranged on the frame 1 . The two displacement driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com