Manufacturing and pressure testing method for jacketed vessel with inner cylinder as inner groove

A technology of inner bevel and inner cylinder, which is applied in the direction of applying stable tension/pressure to test the strength of materials, manufacturing tools, welding equipment, etc., which can solve the difficulty of improving the welding quality of containers and the inability of all inner cylinders to be processed into inner grooves, etc. problems, to achieve the effect of improving production efficiency and quality, improving welding quality, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

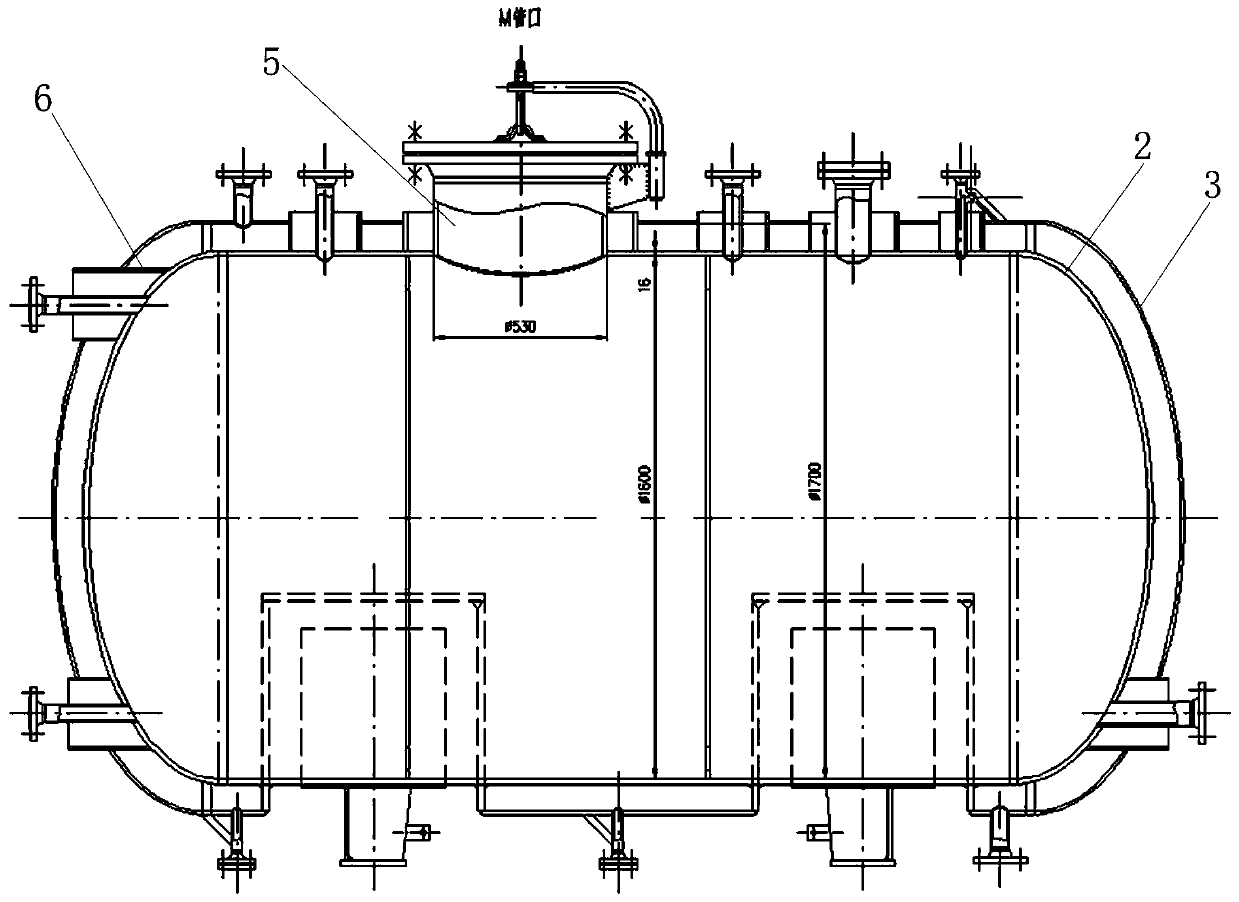

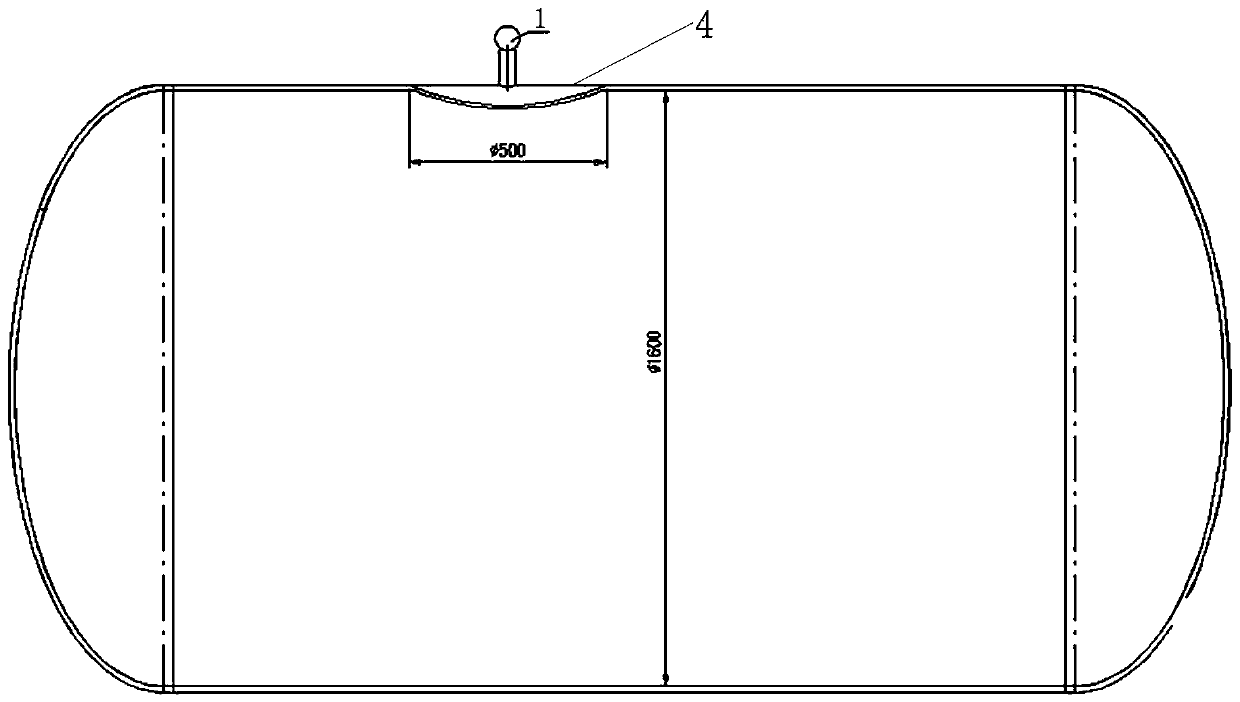

[0015] A manufacturing and pressure testing method of a jacketed vessel with an inner cylinder with an inner bevel, comprising the following steps: (1) opening a hole with a diameter smaller than the manhole in advance at the position where the manhole is to be opened on the inner cylinder, and the remaining pipes of the inner cylinder The interface is also made into an inner groove; the inner cylinder is butt-welded, and the arc plate left by the pre-opening is welded to the pre-opening from the outside, and a hole is opened on the arc plate to connect the water injection pipe and the pressure gauge. cylinder for pressure testing;

[0016] (2) The arc plate can be kept or removed, and the jacket and the inner cylinder are assembled, and the manhole with a diameter larger than the pre-opening and an inner groove is continued to be processed at the position of the pre-opening hole, and the jacket assembly welding is completed After the pressure test;

[0017] (3) Carry out ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com