Continuous rolling production line cold bed material tracking method, device and system and medium

A technology of production line and cooling bed, which is applied in the field of steel manufacturing, can solve the problems of inconvenience for post personnel, long distance between operating table and cooling bed, and influence on process production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In the continuous rolling production line, when the steel billet is rolled and transferred to the rear area of the second bar of steel rolling, it is first cut into bars by 3# flying shears on the continuous rolling line, and each bar after being cut by 3# flying shears, The input roller after the 3# flying shear is transported to the apron, and the up and down movement of the apron moves the bars on it to the cooling bed, and the action of the rack on the cooling bed transports each bar to the output roller. , transported to the cold shear through the output roller table for cold shear shearing.

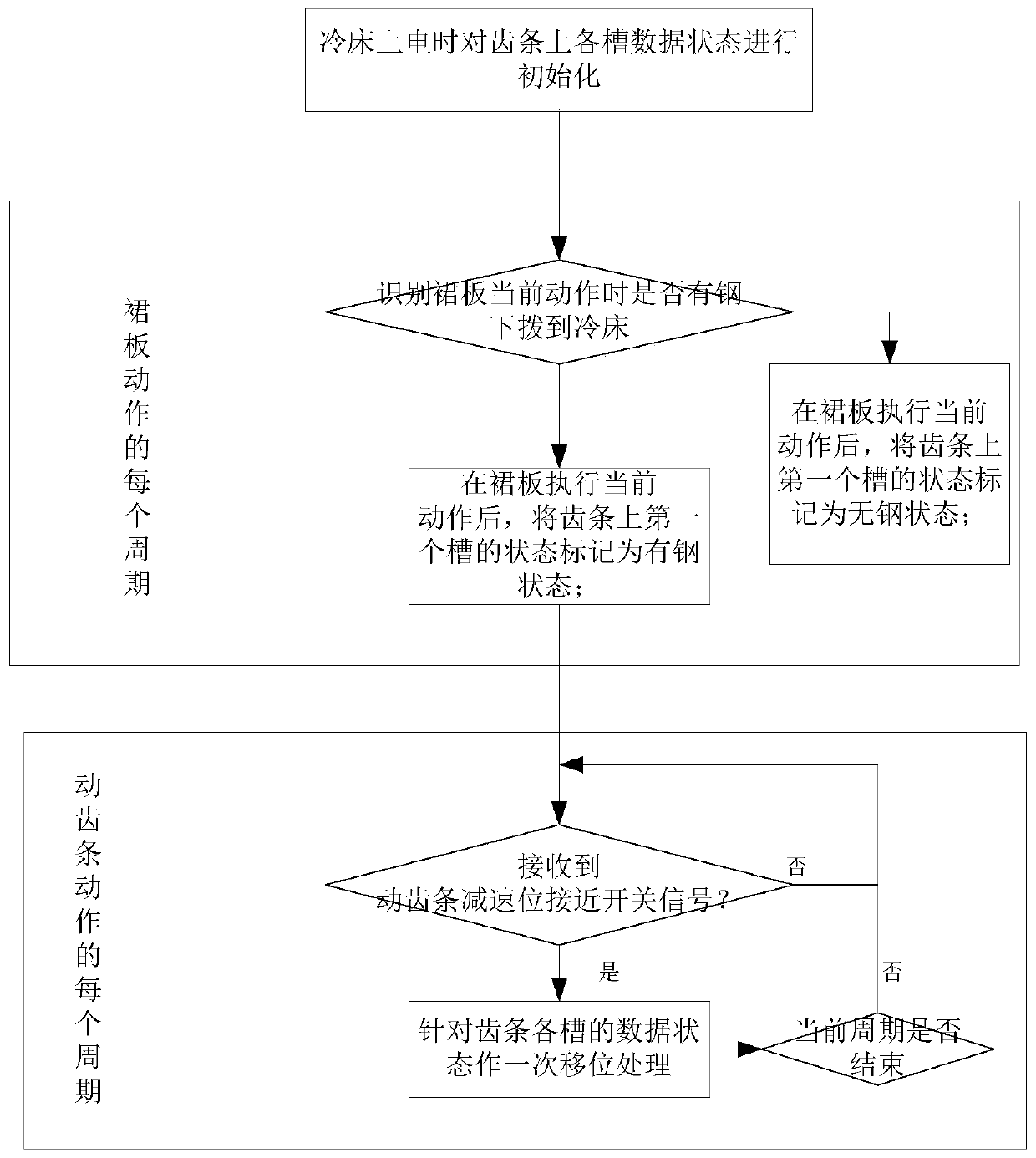

[0051] This embodiment discloses a method for tracking materials in the cooling bed of a continuous rolling production line, such as figure 1 As shown, the steps are as follows:

[0052] Step 1. When powering on the cooling bed, initialize the data state of each slot on each rack of the cooling bed, and initialize them to a steel-free state;

[0053] Step 2. In each cycle...

Embodiment 2

[0064] This embodiment discloses a cooling bed material tracking device for a continuous rolling production line, including:

[0065] The initialization unit is used to initialize the data state of each slot on each rack of the cooling bed when the cooling bed is powered on, all of which are initialized to a steel-free state;

[0066] The identification unit is used to identify whether there is steel lowering on the cooling bed when the skirt board is currently in motion;

[0067] The first groove state marking unit is used to mark the state of the first groove on the rack as the state of the rod tail after the skirt performs the action when the steel is transferred to the cooling bed under the action of the skirt; it is used for When the data state is shifted, the state of the first slot of the rack is marked as the state of no bar tail gauge; the first slot of the rack is the slot closest to the skirt side; it is used for the data of each slot When the state is shifted ever...

Embodiment 3

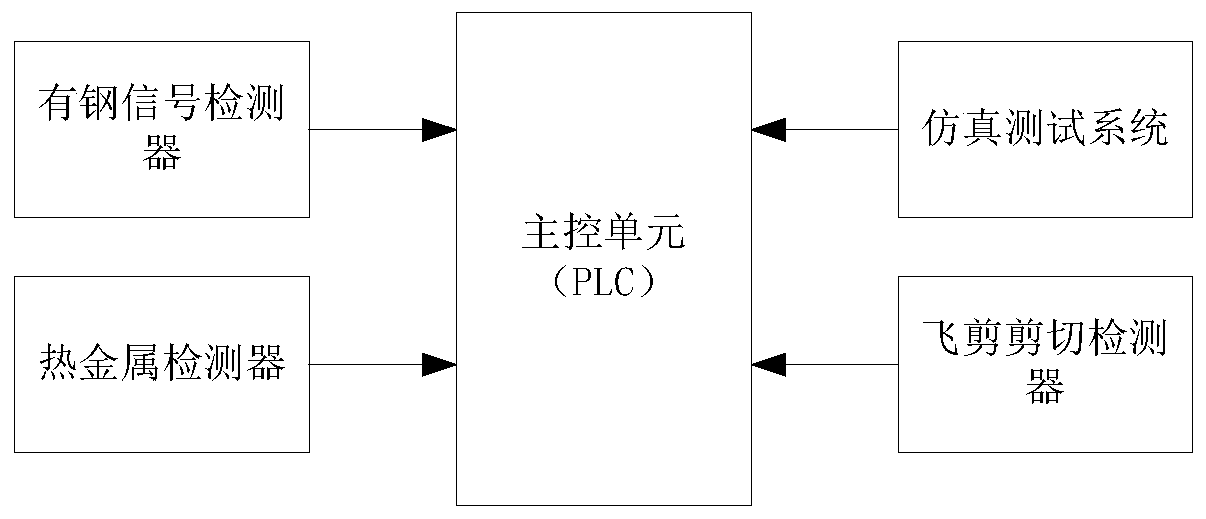

[0077] This embodiment discloses a continuous rolling production line cooling bed material tracking system, such as figure 2 As shown, it includes main control unit, steel signal detector, hot metal detector and flying shear detector. In this embodiment, the main control unit may be a PLC.

[0078] The steel signal detector is used to detect the motor current of the rolling mill in the rolling area. When the motor current is detected to be greater than a certain threshold, it is judged that there is steel in the rolling area, and a steel signal is sent to the main control unit. In the steel signal detector in this embodiment, when the motor current is detected to be greater than 15% to 20% of the rated current, it is judged that there is steel in the rolling area, and a steel signal is sent to the main control unit.

[0079]The hot metal detector is installed on the continuous rolling production line before the first flying shear to detect whether there is a billet passing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com