Regenerative catalytic oxidizer for treating VOCs (Volatile organic compounds) waste gas

A catalytic oxidizer and heat storage technology, applied in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve catalyst burning, catalyst damage, and inability to effectively control the operating temperature of high-temperature oxidation reaction chambers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

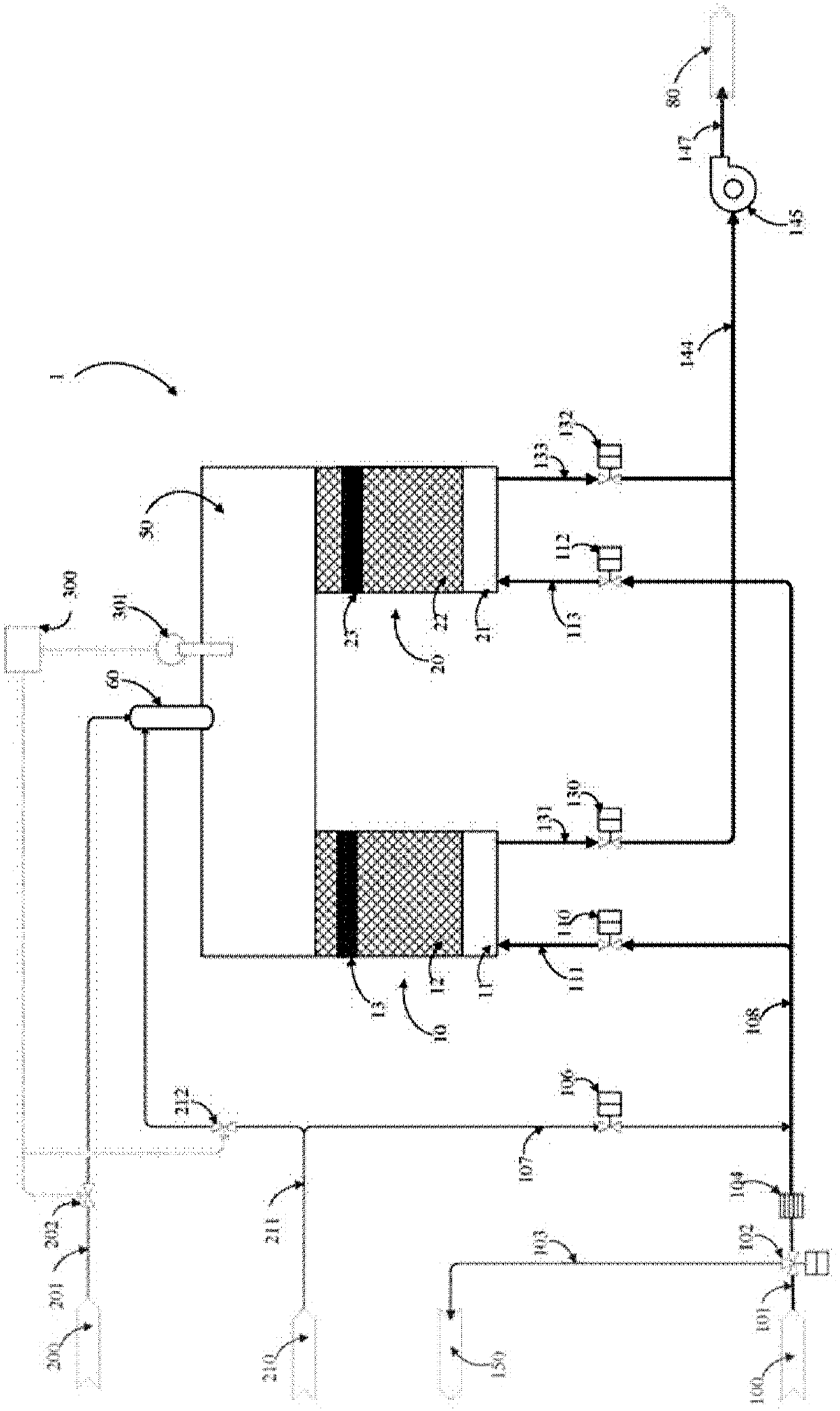

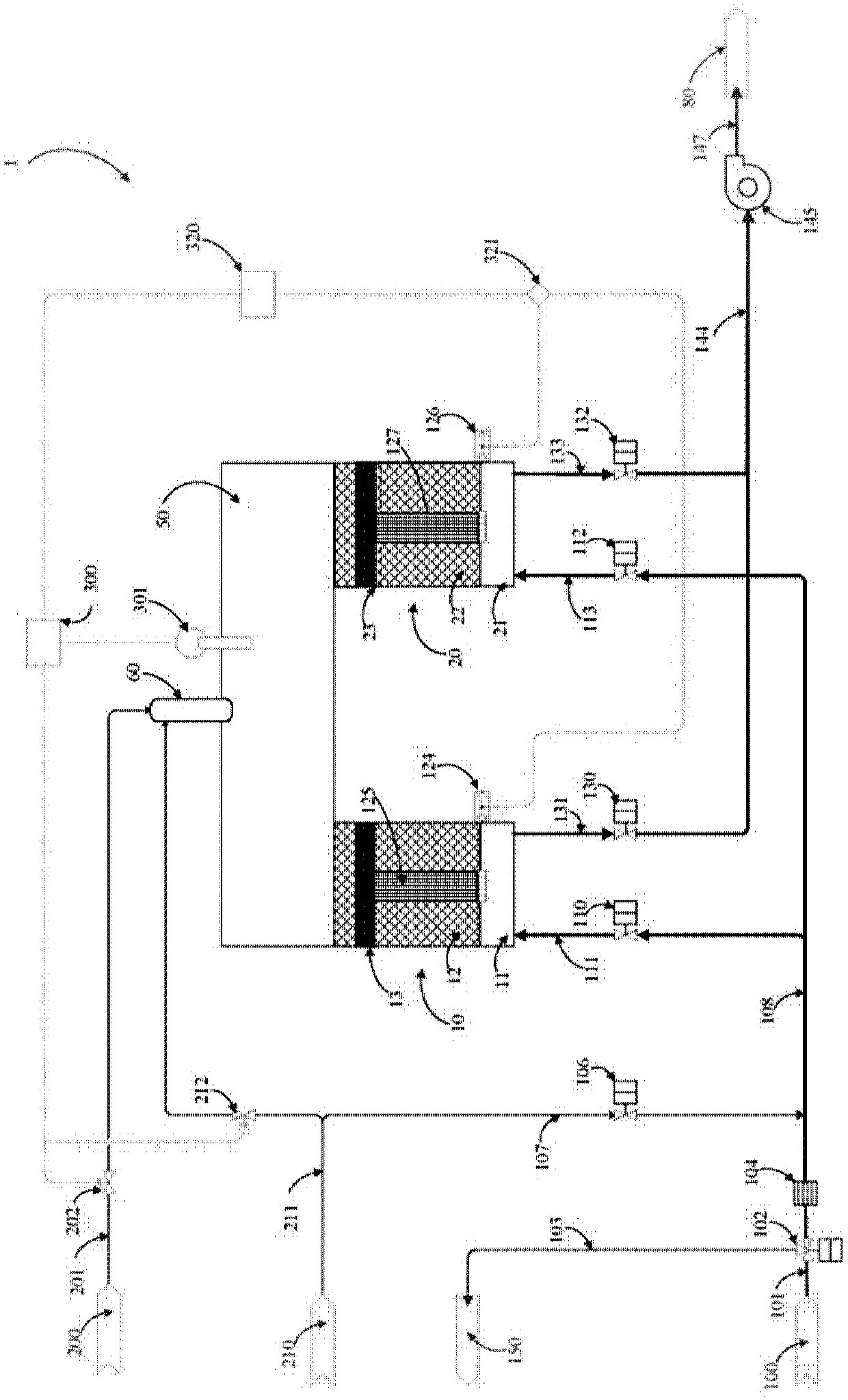

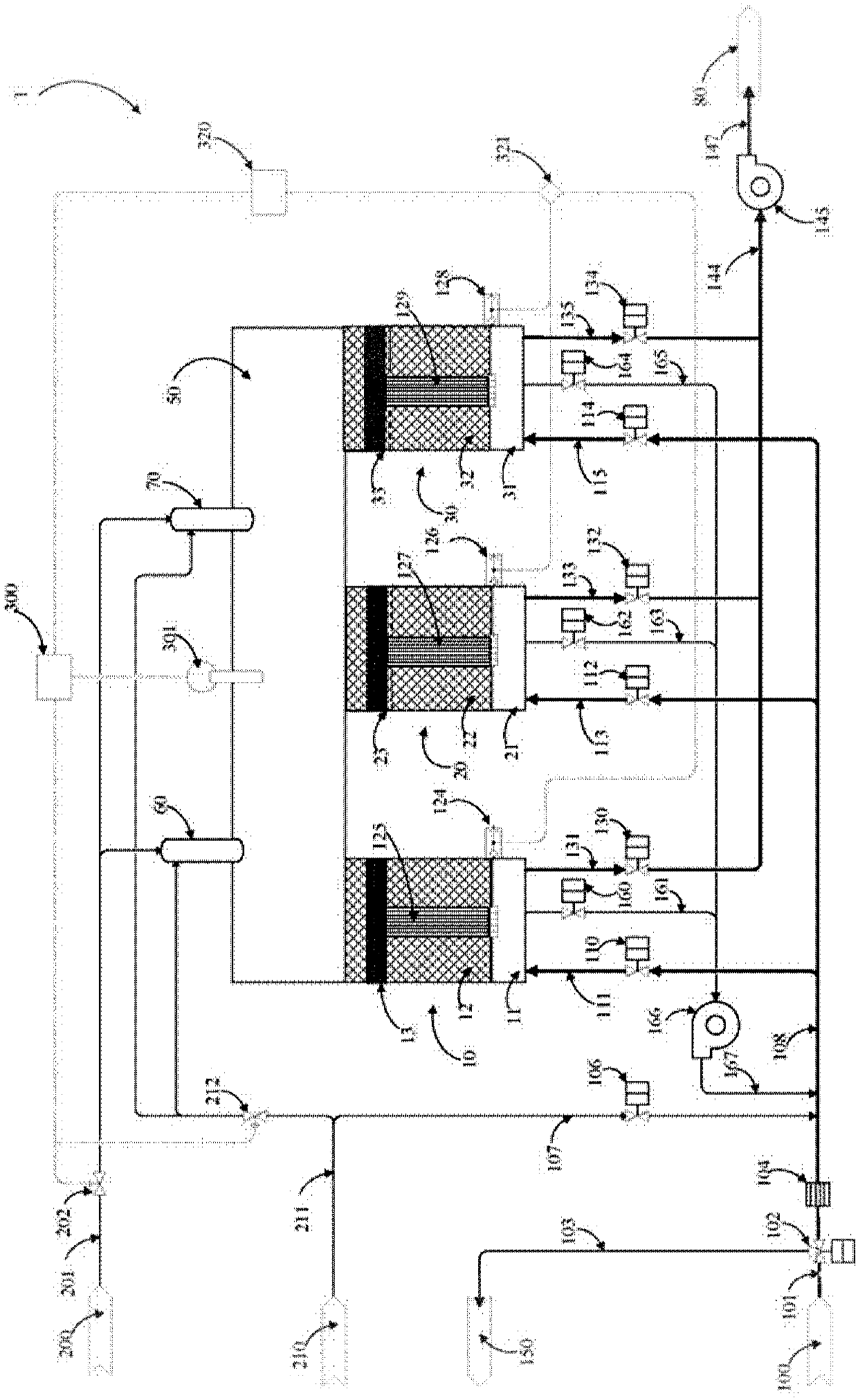

[0093] In order to achieve the above effects, the present invention provides a regenerative catalytic oxidizer 1 capable of treating VOC exhaust gas, which contains at least two catalytic regenerators, a high-temperature oxidation reaction chamber and an over-temperature logic for the high-temperature oxidation reaction chamber In the controller, there is a porous heat storage bed formed by stacking porous materials in the catalytic heat storage chamber, a porous catalyst bed above the porous heat storage bed, the high temperature oxidation reaction chamber is located above the catalytic heat storage chamber and combined with the catalytic heat storage chamber, and In the porous heat storage bed, some porous materials use materials with large porosity and low heat capacity to form the cold bypass fast channel inside the catalytic regenerator, and the cold bypass fast channel in the catalytic regenerator is equipped with automatic temperature control. Flow regulating valve and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com