A device for continuously preparing organosilicon monomers containing special groups and a preparation method using the device

A technology of organosilicon and groups, which is applied in the field of continuous preparation of organosilicon monomers containing special groups, which can solve the problems of potential safety hazards in the preparation method, unsafe production, large consumption, etc., and solve the problems of triggering and heat dissipation , to avoid flushing or explosion, to prevent the effect of blocking valves and pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 equipment

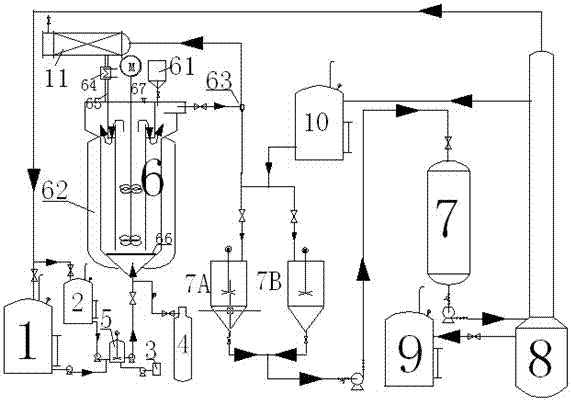

[0043] Such as figure 1 Shown: a device for continuously preparing organosilicon monomers containing special groups provided by the present invention, including: raw material storage 1 / 2, catalyst storage 3, raw gas storage container 4, raw material mixing container 5, and reactor 6 , magnesium feeding bin 61, heating insulation jacket 62, gas-liquid separator 63, condenser 64, glass air condenser 65, support plate 66, liquid feeding port 67, filter device 7A / 7B, filtrate storage 7, distillation tower 8. Product storage 9 , washing solvent storage 10 , tail gas recovery device 11 . The raw material storage container is connected to the raw material mixing container; the raw material mixing container is connected to the raw material gas storage container through a three-way valve; the raw material mixer 1 / 2 is connected to the feed port of the reactor 6; The overflow port of the reactor 6 is connected with the gas-liquid separator 63; the upper o...

Embodiment 2

[0075] Example 2 Preparation Example

[0076] use figure 1 The device shown continuously prepares organosilicon monomers containing special groups. The reactor used is a stirred three-phase fluidized bed reactor made of stainless steel enamel reactor with a diameter of 23cm and a length of 125cm; the lower insulation layer The length is 85cm, the overflow port is 100cm away from the bottom of the reactor, the effective reaction diameter of the reactor is 20cm, and the effective reaction volume is 31.4L.

[0077] A) drying equipment

[0078] The reactor and all piping are to be purged with dry air until dry.

[0079] B) Loading magnesium chips

[0080] Under the protection of inert gas, magnesium chips are fed into the stirred three-phase fluidized bed reactor through the magnesium feeding bin until the 5~50cm above the stirring paddle is buried.

[0081] C) Initiate a reaction

[0082]Heating the reactor means that when the temperature in the reactor reaches 65 degrees Ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com