Methods and systems for spark timing control

A technology of spark timing and intake system, applied in spark ignition controller, electrical control, automatic control and other directions, can solve the problem of torque response time reduction, knocking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

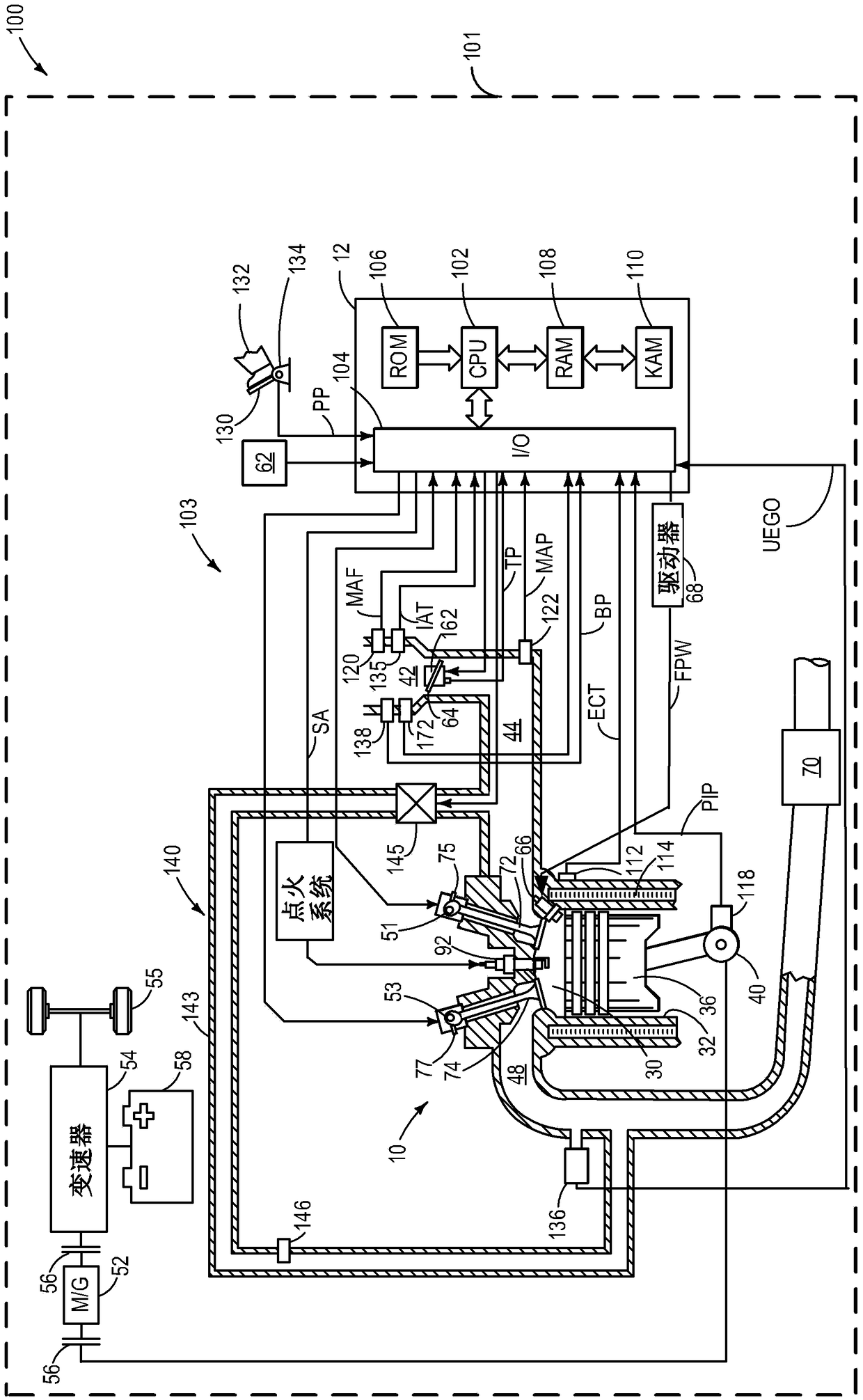

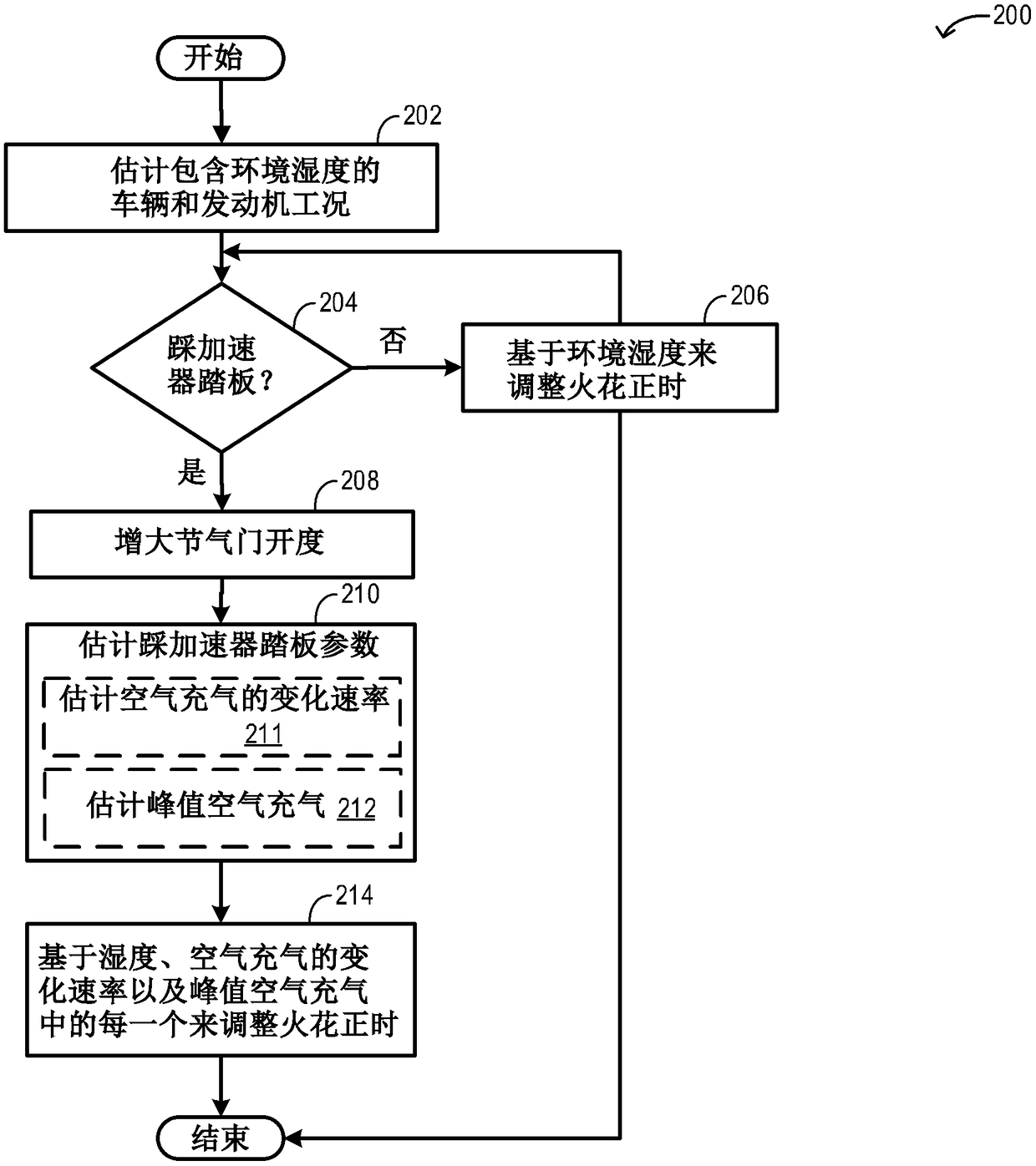

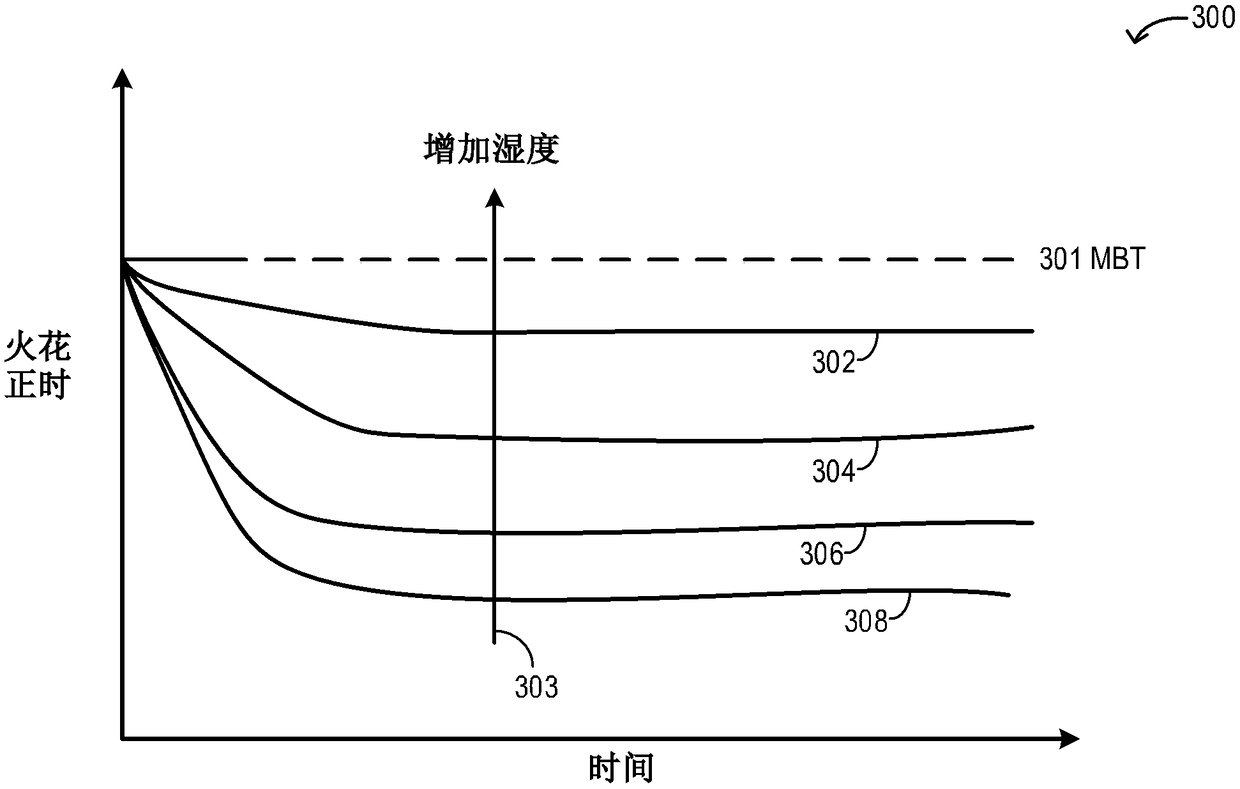

[0017] The following description relates to systems and methods for adjusting spark timing during a tip-in event based on ambient humidity and instantaneous tip-in parameters. An example engine system coupled to a hybrid vehicle is in figure 1 shown in . The engine controller can be configured to execute control routines such as figure 2 Example routine to adjust spark timing during tip-in conditions. Example graphs for adjusting spark timing based on each of humidity, rate of change of air charge, and peak air charge during multiple tip-ins are shown separately at Figure 3A to Figure 3C middle. An example plot with spark timing curves adjusted based on each of humidity, rate of change of air charge, and peak air charge while compensating for synergistic and counterproductive effects is shown at Figure 3D place. Example adjustments to spark timing during a tip-in are shown in Figure 4 middle.

[0018] figure 1 is a schematic diagram illustrating a vehicle system 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com