Salted egg yolk ice cream and preparation method thereof

A technology for salted egg yolk and ice cream, which is applied to the field of salted egg yolk ice cream and its preparation, can solve the problems such as the inability to satisfy the taste of consumers, and achieve the effects of beautiful and attractive color, increased nutritional value and rich flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

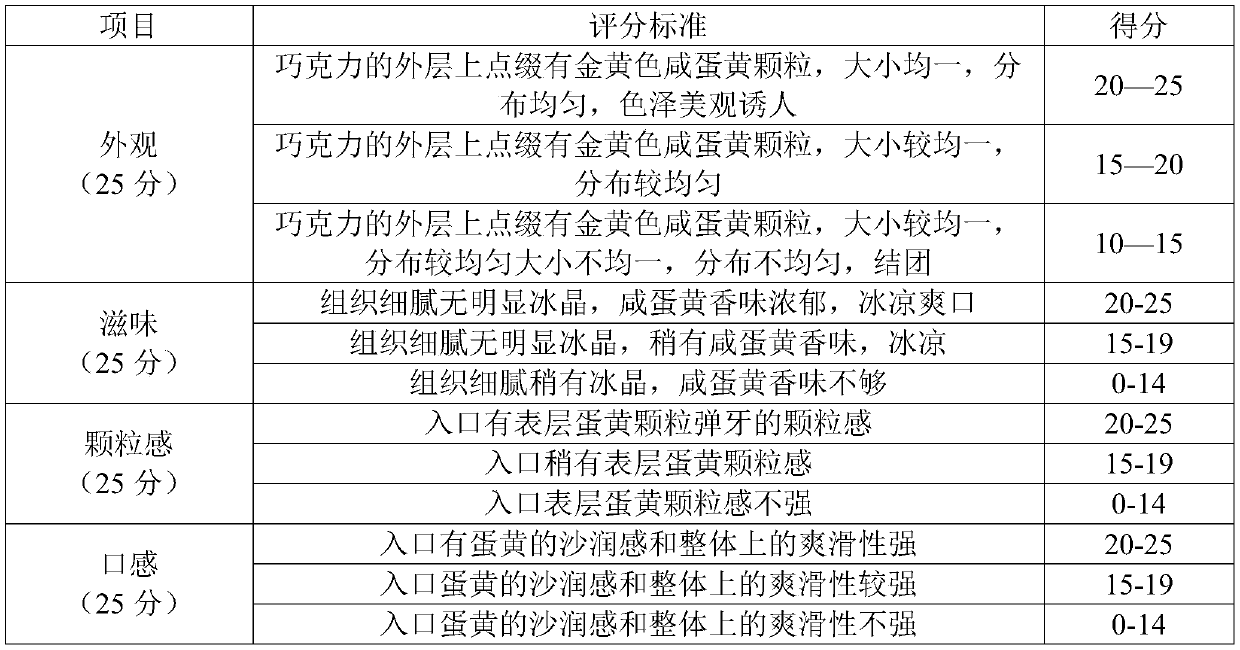

Examples

Embodiment 1

[0027] A salted egg yolk ice cream prepared from the following raw materials in parts by weight: 40.8 parts of water, 15 parts of butter, 10 parts of whole milk powder, 6 parts of butter, 6 parts of vegetable oil, 5 parts of sweetener, 2 parts of cocoa powder, 0.2 parts of emulsifier, 10 parts of salted egg yolk paste, 5 parts of salted egg yolk granules;

[0028] Wherein, the vegetable oil is obtained by stirring and mixing olive oil, corn oil, and rapeseed oil in a mass ratio of 1:1:1; the sweetener is obtained by white granulated sugar, L-arabinose, xylitol, isomaltose Alcohol is mixed and obtained by mass ratio 1:1:1:1; Described emulsifier is by mass ratio 1: Stir and mix at 1:1:1; the salted egg yolk is baked at 170°C for 30 minutes, taken out and crushed, then baked at 120°C for 30 minutes, passed through a colloid mill and crushed to 20 μm, with a salt content of 1.7%; The salted egg yolk granules are salted egg yolks baked at 150°C for 35 minutes, frozen at -18°C for...

Embodiment 2

[0037] A salted egg yolk ice cream prepared from the following raw materials in parts by weight: 35.8 parts of water, 12 parts of butter, 8 parts of whole milk powder, 5 parts of butter, 8 parts of vegetable oil, 6 parts of sweetener, 3 parts of cocoa powder, 0.2 parts of emulsifier, 15 parts of salted egg yolk paste, 7 parts of salted egg yolk granules;

[0038] Wherein, the vegetable oil is obtained by stirring and mixing olive oil, corn oil, and rapeseed oil in a mass ratio of 1:2:1; the sweetener is obtained by white granulated sugar, L-arabinose, xylitol, isomaltose Alcohol is mixed and obtained by mass ratio 1:1:2:1; Described emulsifier is by mass ratio 1: Stir and mix at 1:1:1; the salted egg yolk paste is baked at 180°C for 35 minutes, taken out and crushed, then baked at 130°C for 30 minutes, passed through a colloid mill and crushed to 30 μm, with a salt content of 1.7%; The salted egg yolk granules are salted egg yolks baked at 160°C for 35 minutes, frozen at -18°...

Embodiment 3

[0047] A salted egg yolk ice cream prepared from the following raw materials in parts by weight: 38.8 parts of water, 11 parts of butter, 9 parts of whole milk powder, 6 parts of butter, 8 parts of vegetable oil, 1 part of sweetener, 2 parts of cocoa powder, 0.2 parts of emulsifier, 17 parts of salted egg yolk paste, 7 parts of salted egg yolk granules;

[0048] Wherein, the vegetable oil is obtained by stirring and mixing olive oil, corn oil, and rapeseed oil in a mass ratio of 1:2:1; the sweetener is obtained by white granulated sugar, L-arabinose, xylitol, isomaltose Alcohol is mixed and obtained by mass ratio 1:1:2:1; Described emulsifier is by mass ratio 1: 2:2:1 Stirring and mixing; the salted egg yolk is baked at 200°C for 35 minutes, taken out and crushed, then baked at 150°C for 30 minutes, passed through a colloid mill and crushed to 30 μm, with a salt content of 1.7%; The salted egg yolk granules are salted egg yolks baked at 180°C for 45 minutes, frozen at -18°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com