Elastic mesh type straw compression pair roller

A straw and elastic technology, which is applied in the field of elastic meshing straw compression rollers, can solve the problems of non-feeding, non-compacting, and leakage of straw, and achieve the solution of non-feeding or discontinuous feeding of straw and prevention of leakage or uncompacted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

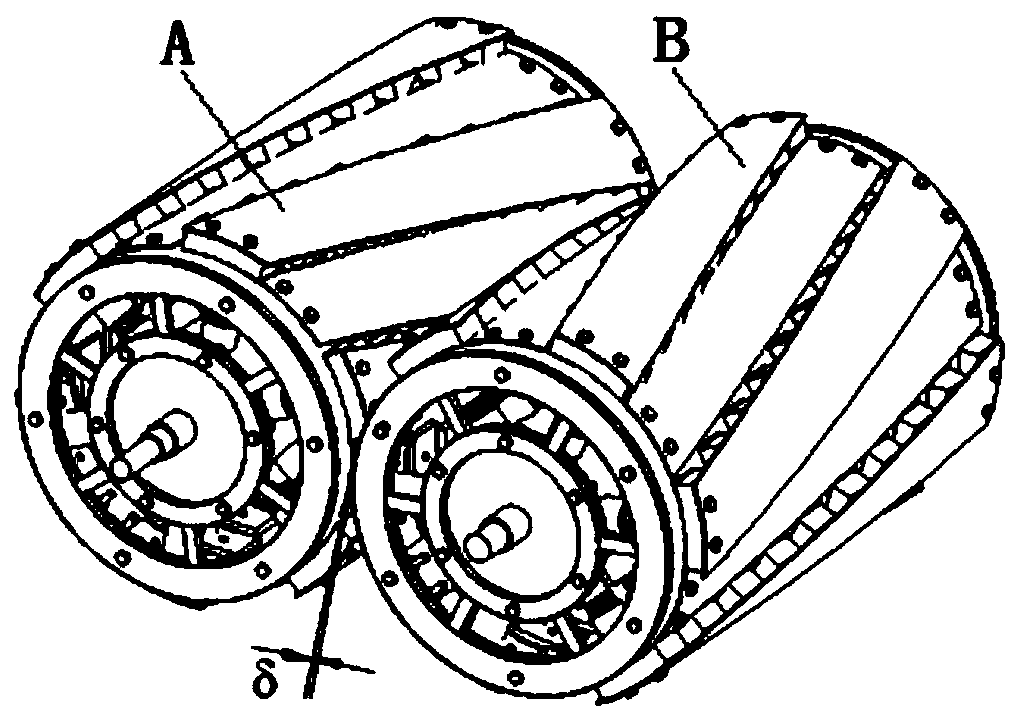

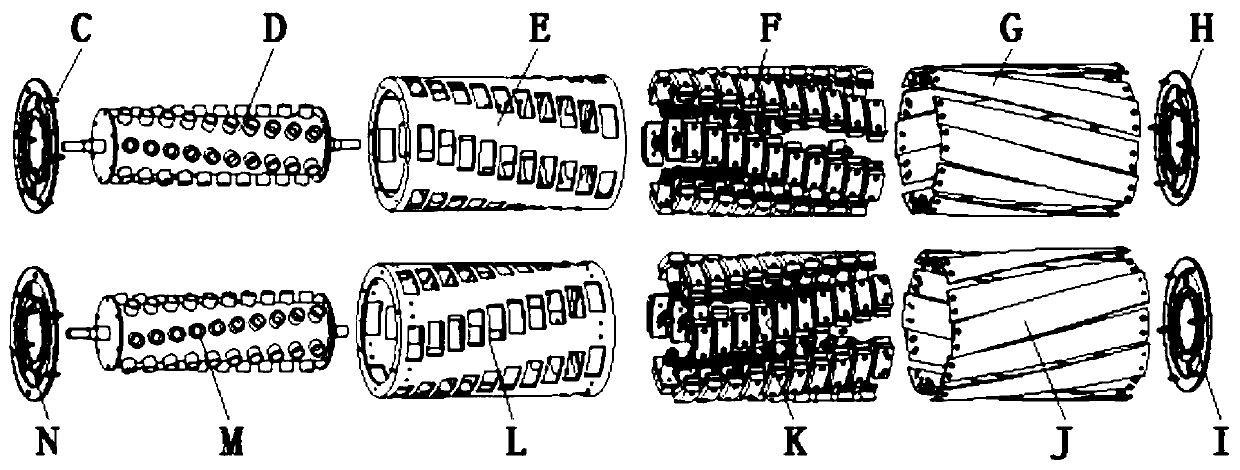

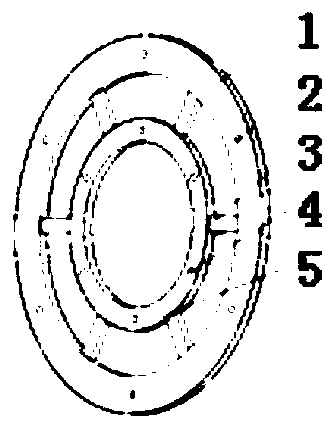

[0031] like figure 1 , figure 2 , Figure 11 and Figure 13 As shown, the present invention is composed of the first pressing roller assembly A and the second pressing roller assembly B, the first pressing roller assembly A and the second pressing roller assembly B have the same structure, the directions are opposite, and they are screw meshed and installed, and the installation gap δ=0 -5mm; where the first pressure roller assembly A is composed of left end cover assembly IC, pressure roller shaft assembly ID, roller assembly IE, shrapnel assembly IF, rubber strip assembly IG and right end cover assembly IH; the second pressure roller assembly B consists of the right end The cover assembly ⅡI, the rubber strip assembly ⅡJ, the shrapnel assembly ⅡK, the roller assembly ⅡL, the pressure roller shaft assembly ⅡM and the left end cover assembly ⅡN; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com