Well cementing and completion pipe string and method

A well completion string and well cementing technology, applied in the direction of wellbore/well parts, drill pipe, casing, etc., can solve problems such as failure of cementing and completion operations, oil layer pollution, and limited oil layer pressure bearing capacity, etc. Oil layer leakage problem, avoid pollution, improve the effect of success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Unless otherwise defined, all technical terms used in the embodiments of the present invention have the same meanings as commonly understood by those skilled in the art. In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

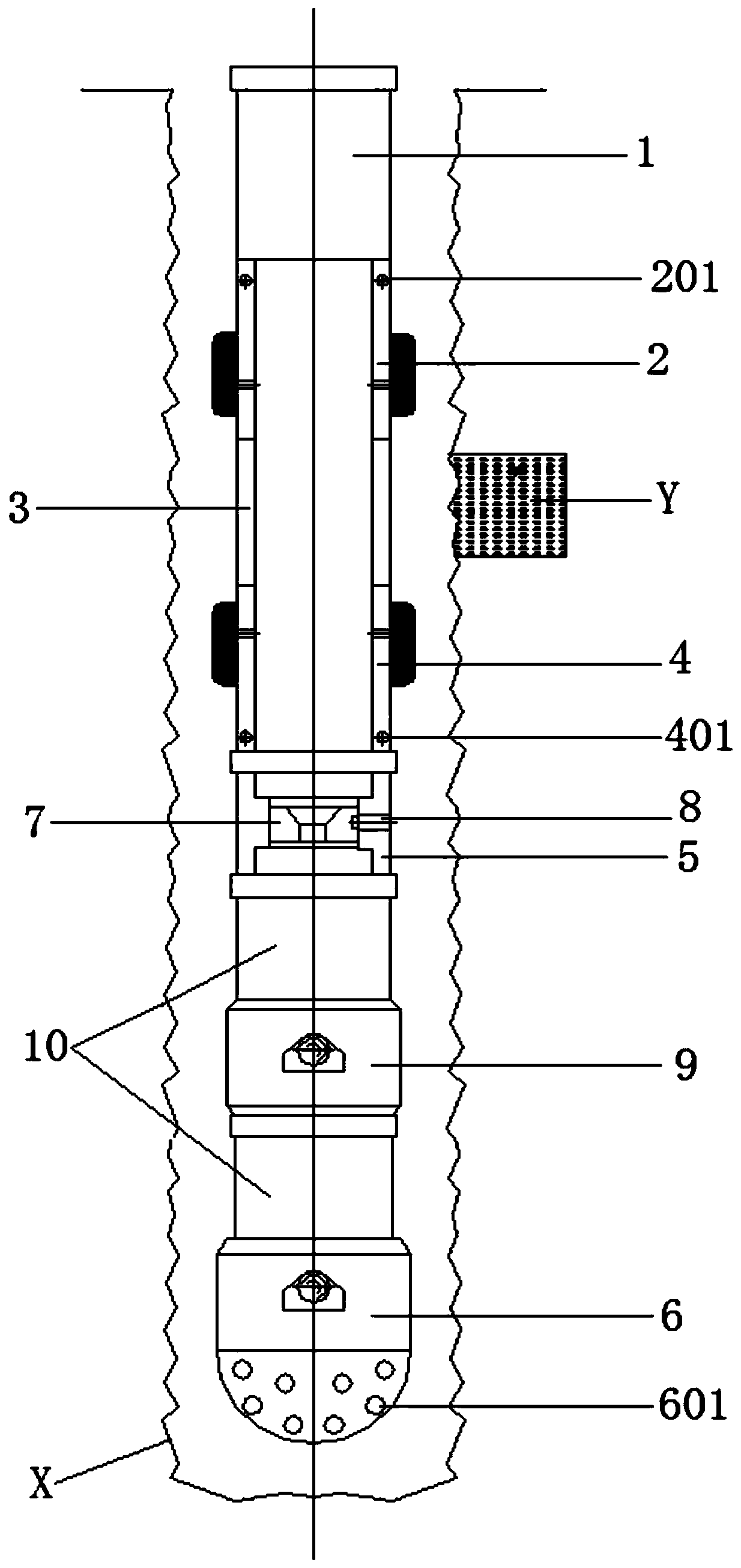

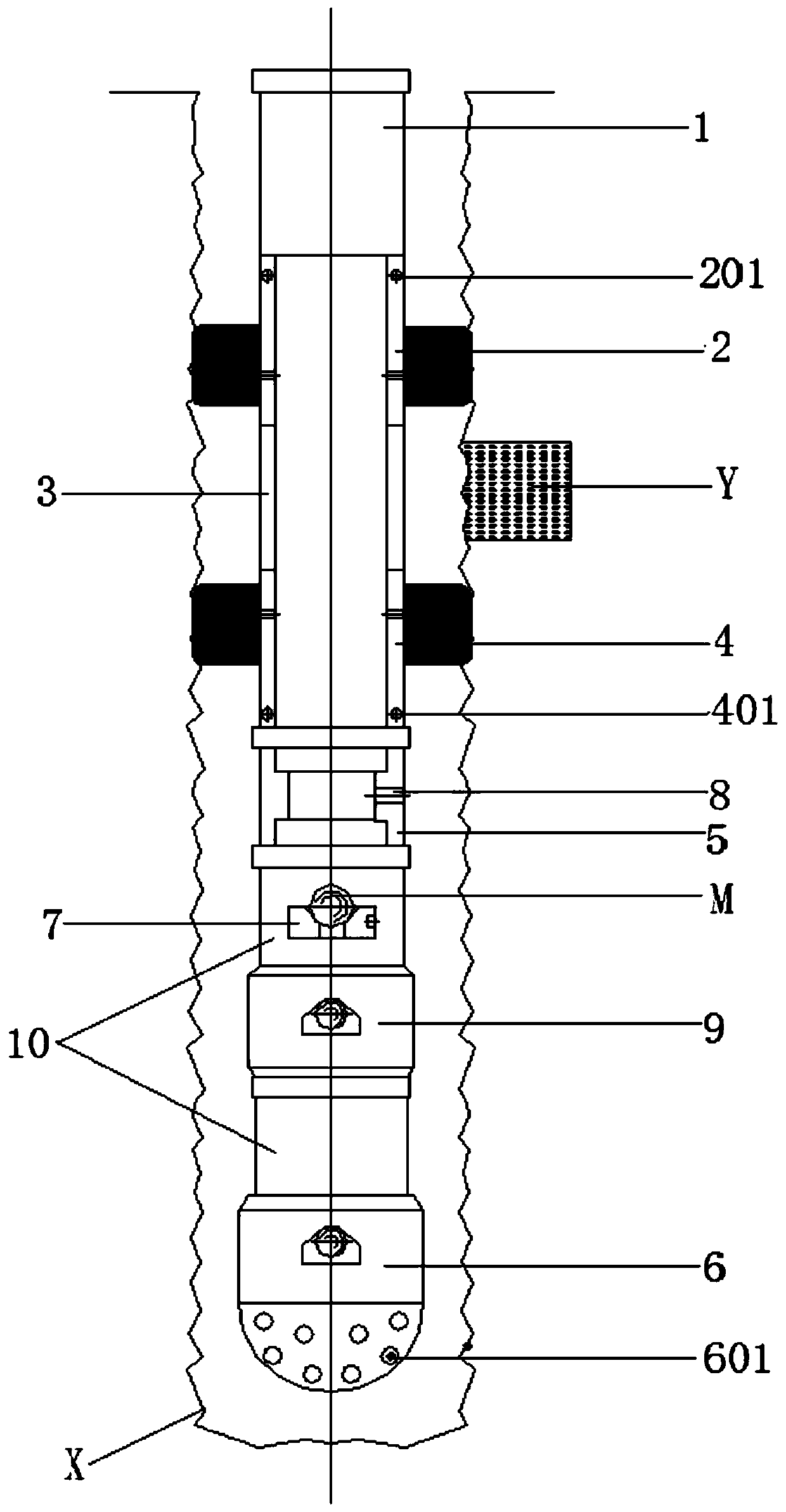

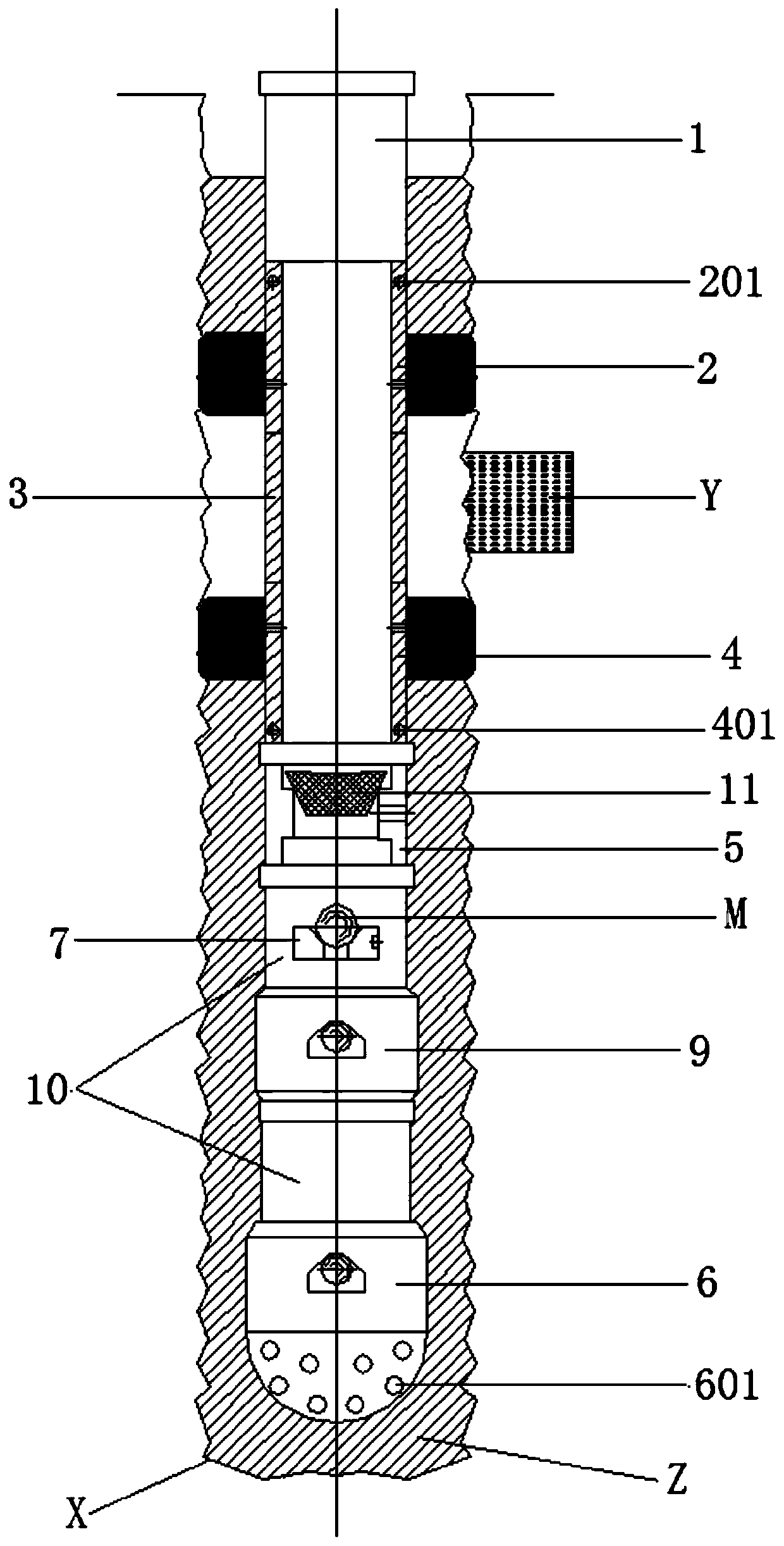

[0053] In the first aspect, the embodiment of the present invention provides a cementing and completion string, as shown in the attached figure 1 As shown, the string includes: a casing string 1 , an upper packer 2 , an annulus sleeve 3 , a lower packer 4 , a ball seat sleeve 5 , and a floating shoe 6 , which are sequentially connected and conducted from top to bottom.

[0054] Further, the pipe string also includes a ball seat 7 which is set in the ball seat sleeve 5 through a shear pin 8 .

[0055] The upper end of the upper packer 2 is provided with a cement slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com