Harmonic microscopic measurement method based on sheet-light microscopy and confocal slit detection

A microscopic measurement and harmonic technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of unfavorable microscopic imaging of living samples, reduce the image acquisition rate, etc., to achieve enhanced contrast and resolution, The effect of increasing the rate and suppressing background noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The implementation examples of the present invention will be described in detail below in conjunction with the accompanying drawings.

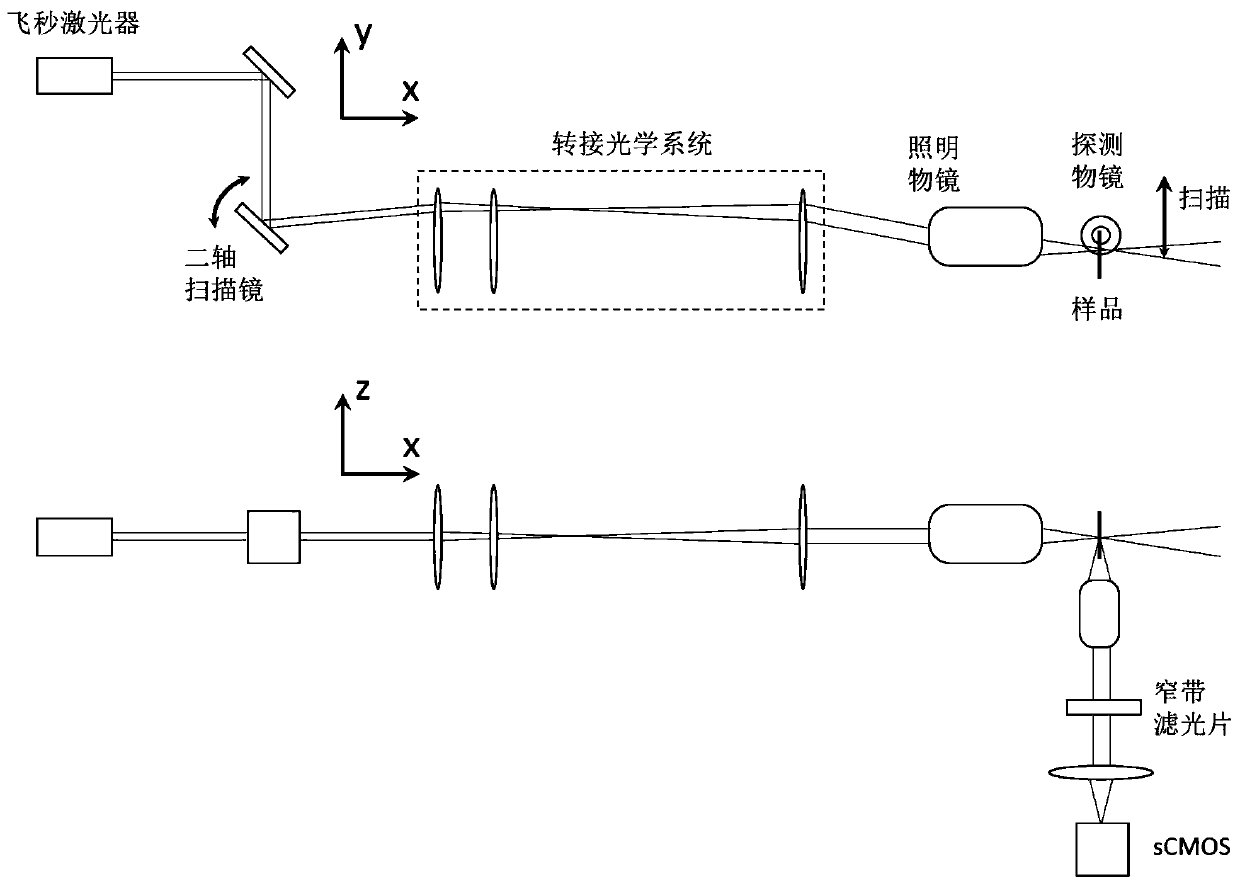

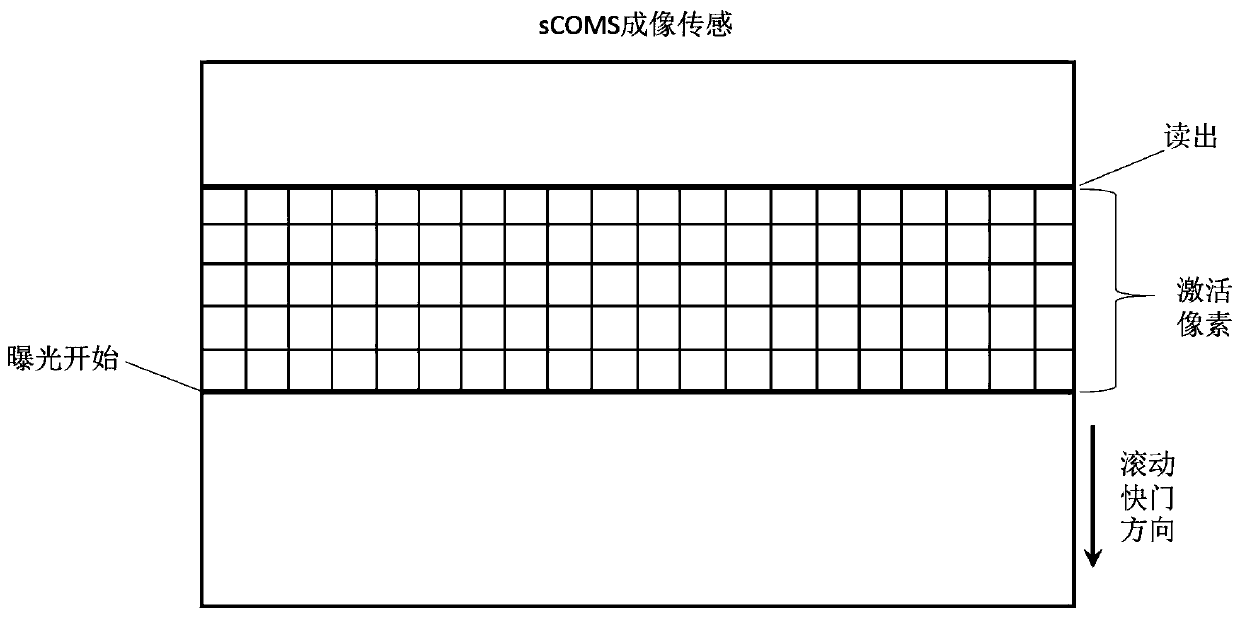

[0013] The schematic diagram of the harmonic microscopic measurement method based on sheet light microscopy and confocal slit detection in this embodiment is as follows figure 1 shown. The detection direction of the harmonic signal is perpendicular to the sample illumination direction, so as to realize the sheet light measurement in harmonic microscopy. Confocal slit detection is realized by using sCMOS as the detector and using rolling shutter working mode. The femtosecond laser pulse is reflected by the scanning galvanometer and enters the transfer optical system for spherical aberration compensation, and then the microscopic objective lens converges inside the sample to form the excitation focus spot required for harmonic signal generation. The harmonic signal excited by the sample is collected by the detection objective lens perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com