Ship fuel oil monitoring and opposite bank internet-of-things management system

A management system and Internet of Things technology, which is applied in the field of ship fuel oil monitoring and on-shore Internet of Things management system, can solve the problems of insufficient timeliness of information interaction, the urgency of stopping, and the inability to pursue accountability after the event, so as to reduce the risk of fuel oil theft and improve Shipping safety, the effect of supervising the crew's work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

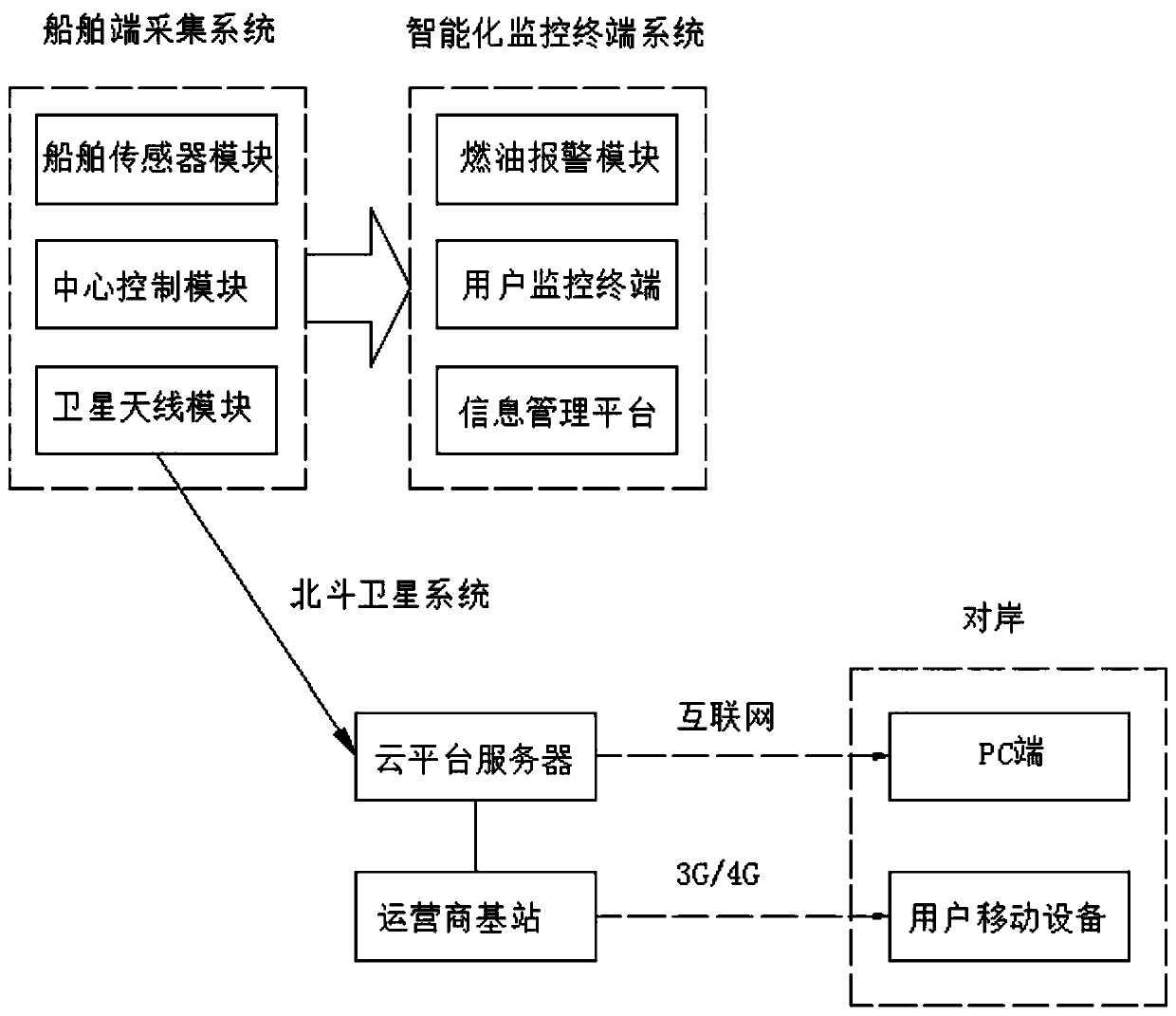

[0043] see figure 1 , a ship fuel oil monitoring and shore-side Internet of Things management system, including a ship-side collection system, an intelligent monitoring terminal system, and a power supply system. The power supply system includes a main power supply and a backup power supply. Emergency start to ensure the normal operation of the system. You can also write the timing program to the backup power supply after predicting the shutdown time of the main power supply. When the main power supply fails, the backup power supply will supply power immediately. The control module and satellite antenna module, the ship sensor module includes flowmeter, oil pressure sensor, odometer and speed sensor, and the ship sensor module is connected with the central control module based on the RS485 bus standard.

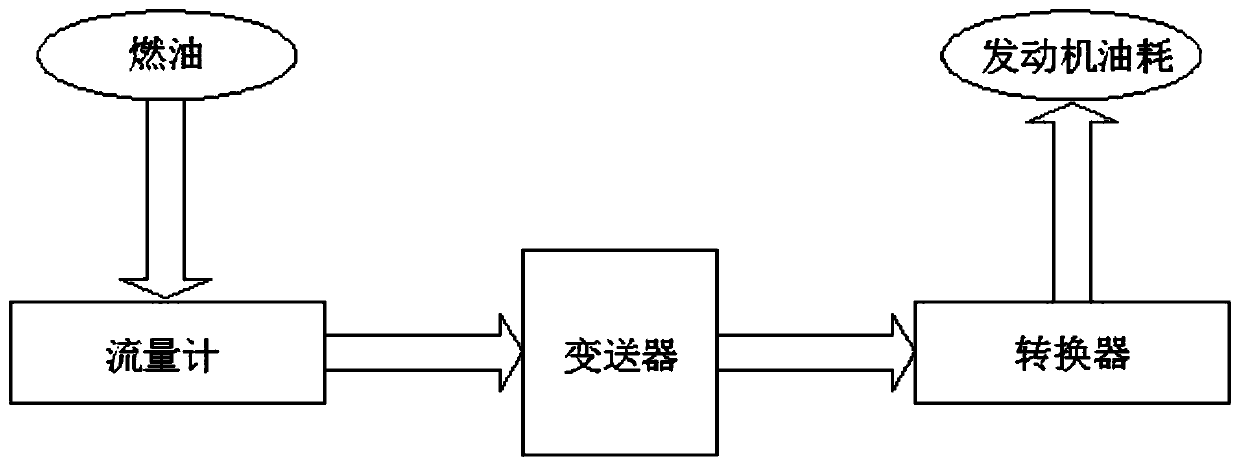

[0044] see figure 2 The flow meter method to measure fuel consumption is to connect the flow meter to the fuel pipeline of the internal combustion engine, and the flow sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com