Preparation method of magnetic response self-repairing intelligent hydrogel

A self-healing and magnetic response technology, applied in the field of hydrogel preparation, can solve the problems of soft texture and poor plasticity, and achieve the effects of good biocompatibility, short self-healing time, and long useful life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

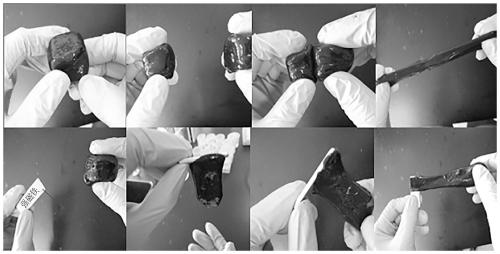

Image

Examples

Embodiment 1

[0033] A method for preparing a magnetically responsive self-healing smart hydrogel, comprising the following steps:

[0034] (1) Preparation of ferric oxide microparticles: Weigh 9.12g of ferrous sulfate heptahydrate and 21.7g of ferric chloride hexahydrate and dissolve them in 50mL of distilled water, then add 50mL of ammonia water to the system, heat in a water bath at 40°C and 1000rmp , after the solution turns from light brown to black, continue to react for 30 minutes, then raise the temperature to 80°C to make it completely crystallized, and obtain magnetic ferric oxide microparticles;

[0035] (2) Preparation of polyvinyl alcohol solution: Weigh 5 g of polyvinyl alcohol solids, add them to 45 g of distilled water, heat and stir in a water bath at 90° C. at a stirring speed of 500 rpm, and continue for 2 hours until the polyvinyl alcohol is completely dissolved to obtain a uniform solution;

[0036] (3) Preparation of cross-linking solution: Weigh 1.5 g of boric acid po...

Embodiment 2

[0043] A method for preparing a magnetically responsive self-healing smart hydrogel, comprising the following steps:

[0044] (1) Preparation of ferric oxide microparticles: Weigh 9.12g of ferrous sulfate heptahydrate and 21.7g of ferric chloride hexahydrate and dissolve them in 50mL of distilled water, then add 50mL of ammonia water to the system, heat in a water bath at 40°C and 1000rmp , after the solution turns from light brown to black, continue to react for 30 minutes, then raise the temperature to 80°C to make it completely crystallized, and obtain magnetic ferric oxide microparticles;

[0045] (2) Preparation of polyvinyl alcohol solution: Weigh 5 g of polyvinyl alcohol solids, add them to 45 g of distilled water, heat and stir in a water bath at 90° C. at a stirring speed of 500 rpm, and continue for 2 hours until the polyvinyl alcohol is completely dissolved to obtain a uniform solution;

[0046] (3) Preparation of cross-linking solution: Weigh 0.5 g of boric acid po...

Embodiment 3

[0051] A method for preparing a magnetically responsive self-healing smart hydrogel, comprising the following steps:

[0052] (1) Preparation of ferric oxide microparticles: Weigh 9.12g of ferrous sulfate heptahydrate and 21.7g of ferric chloride hexahydrate and dissolve them in 50mL of distilled water, then add 50mL of ammonia water to the system, heat in a water bath at 40°C and 1000rmp , after the solution turns from light brown to black, continue to react for 30 minutes, then raise the temperature to 80°C to make it completely crystallized, and obtain magnetic ferric oxide microparticles;

[0053] (2) Preparation of polyvinyl alcohol solution: Weigh 5 g of polyvinyl alcohol solids, add them to 45 g of distilled water, heat and stir in a water bath at 90° C. at a stirring speed of 500 rpm, and continue for 2 hours until the polyvinyl alcohol is completely dissolved to obtain a uniform solution;

[0054] (3) Preparation of cross-linking solution: Weigh 0.5 g of boric acid po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com