Method and device for preparing 5-hydroxymethylfurfural through high fructose corn syrup

A technology of hydroxymethylfurfural and fructose syrup, applied in the direction of organic chemistry, can solve the problems of high fructose price, complex system, low yield, etc., and achieve the effects of reducing the discharge of three wastes, simple equipment, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

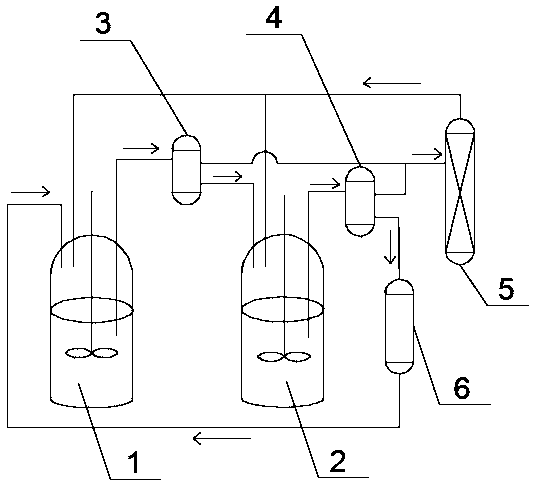

[0023] Such as figure 1 As shown, 0.25 L of HCl and 0.75 L of MIBK with a concentration of 0.5 mol / L were pre-added in the reactor I1; ZnCl was pre-added in the reactor II2 2 Concentration of 0.25mol / L aqueous solution 0.25L, MIBK 0.75L. Control the temperature of reactor Ⅰ1 and reactor Ⅱ2 to be 100 o C and 180 o c. Fructose and glucose with a total mass fraction of 25% fructose syrup solution (F55 type, HCl to adjust pH = 0.3) and MIBK were injected into the continuous reactor I1 with a pump, the residence time of the aqueous solution was 60 minutes, and the residence time of the organic phase was 6 minutes. At the same time, the reaction liquid in the continuous reactor I1 is pumped out to the liquid separation tower I3. After liquid separation, the organic phase is transferred to the vacuum distillation tower 5 to obtain the crude product 5-hydroxymethylfurfural after vacuum distillation, and the organic phase MIBK is reused. The water phase in the separator Ⅰ3 is adju...

Embodiment 2

[0025] The difference between this example and Example 1 is that in this example, the B acid added in advance in the reactor I1 is HCl with a concentration of 0.75 mol / L, and the L acid added in the reactor II2 has a concentration of 0.05 mol / L ZnCl 2 , and the organic phase MIBK is replaced by toluene, and the residence time of toluene in the double continuous reactor is 10min. Finally, the yield of crude 5-hydroxymethylfurfural obtained through continuous reaction was 72%.

Embodiment 3

[0027] The difference between this example and Example 1 is: in this example, the B acid added in advance in the reactor I1 is HCl with a concentration of 0.25 mol / L, and the L acid added in the reactor II2 has a concentration of 0.15 mol / L ZnCl 2 , and replace the organic phase MIBK with CH 2 Cl 2 , CH 2 Cl 2 The residence time in the double continuous reactor is 10min. Finally, the yield of crude 5-hydroxymethylfurfural obtained through continuous reaction was 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com