Distillate spirit canning and filtering equipment

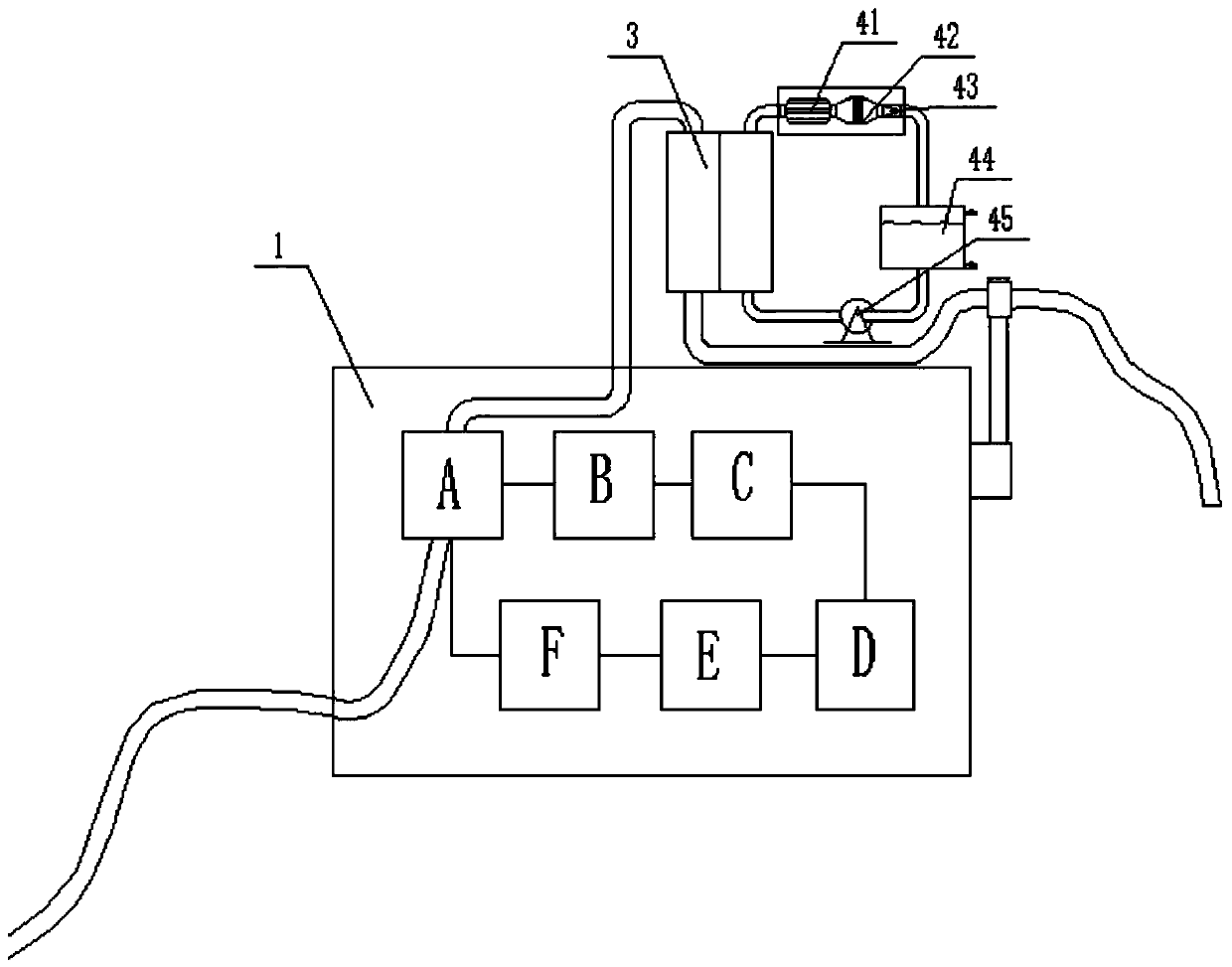

A filtration equipment and canning technology, applied in the field of liquor canning filtration equipment, can solve the problems of unsatisfactory filtration effect, inaccurate filling accuracy, affecting the quality of liquor, etc., and achieve the effects of low cost, speeding up efficiency, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

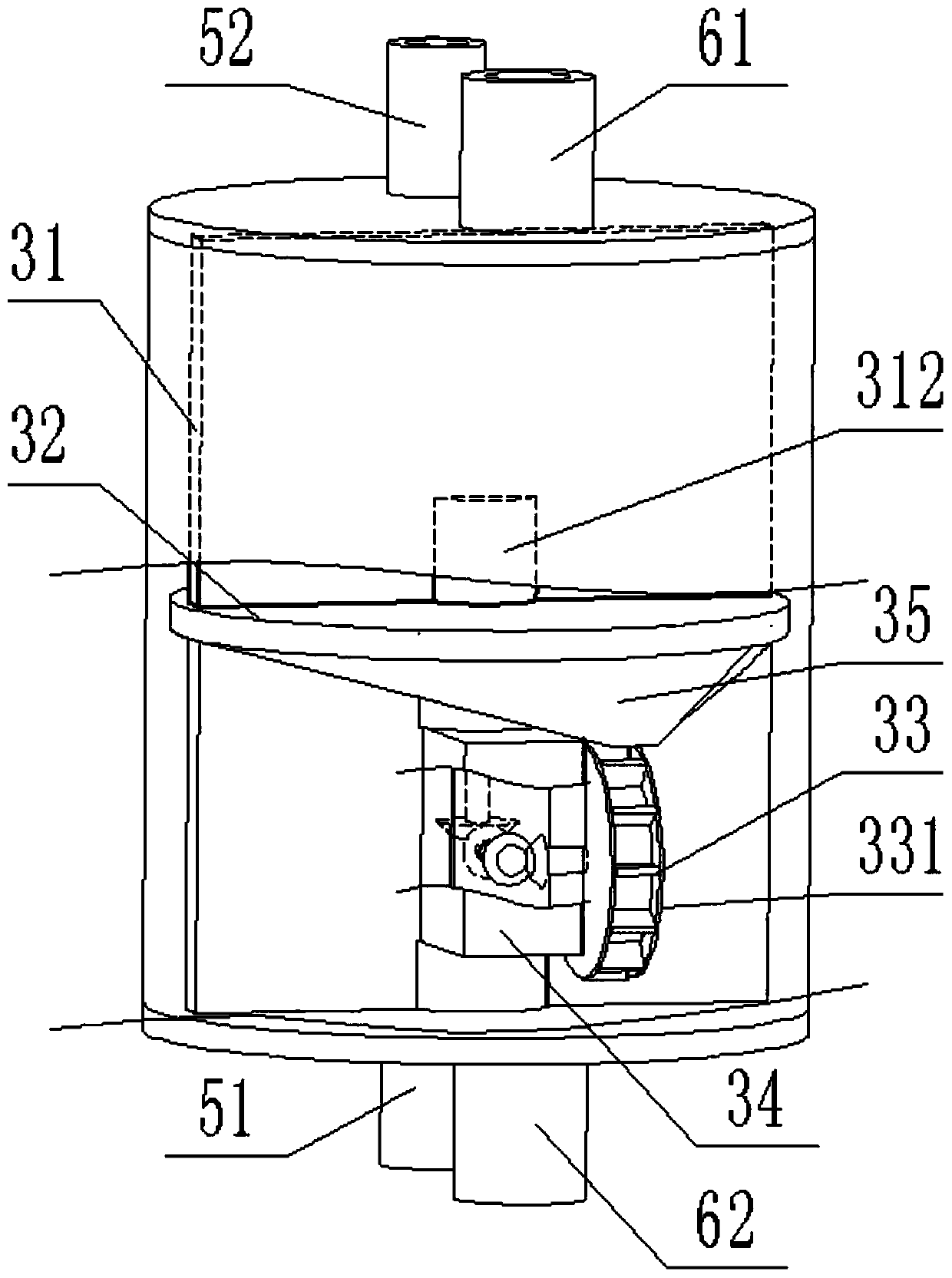

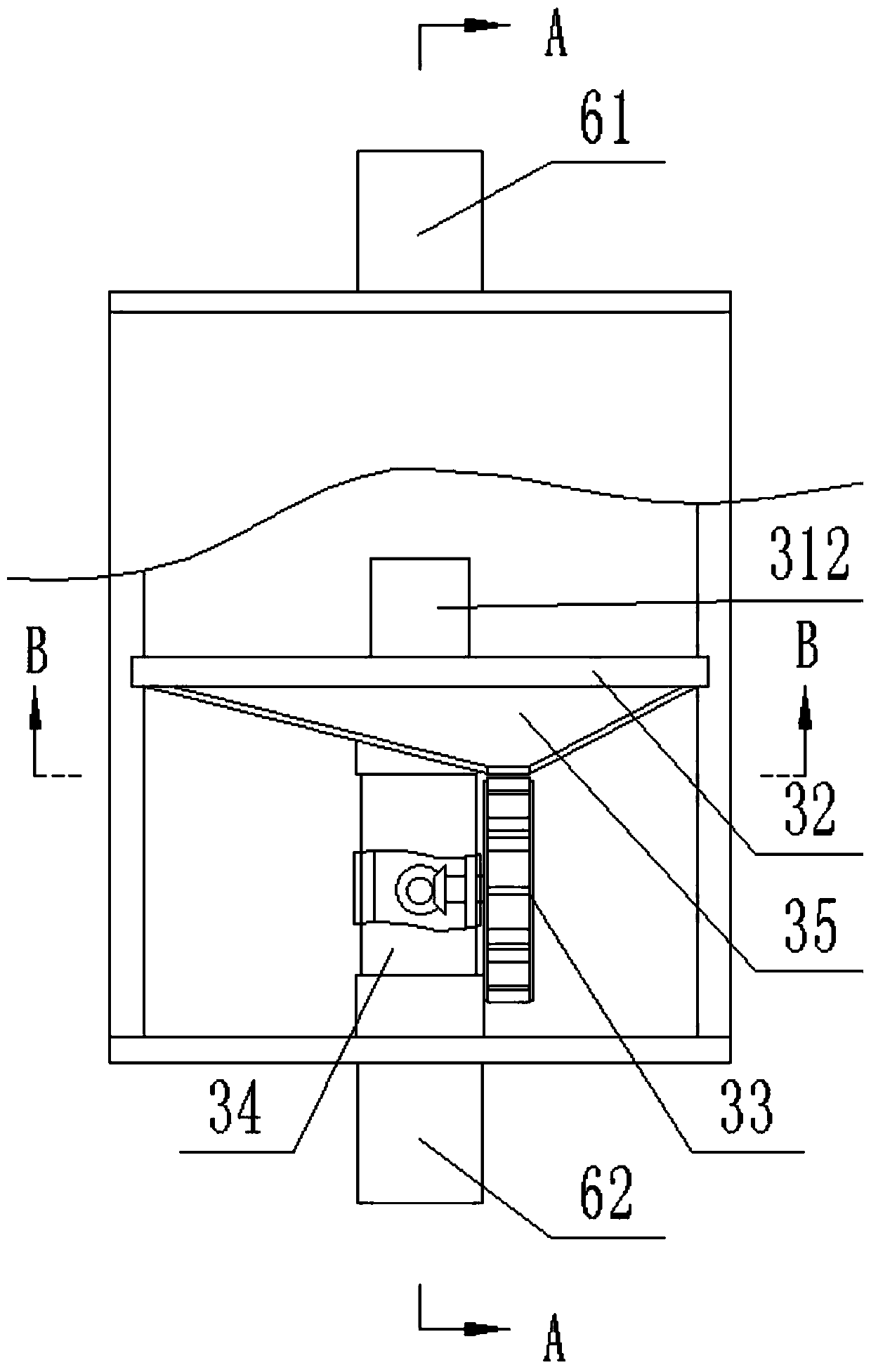

[0042] Embodiment 2: When canning, the wine liquid that needs to be filled is injected into the liquid storage tank through the front end of the supercharger to remove the solid matter in the wine liquid; then open the filling machine and adjust the time switch and current controller according to the demand and then Step on the pedal to make the filling body run. When the canning is in progress, the wine liquid is pumped into the canning body by a small electric pump and sent to the filter chamber of the filter barrel for filtration to remove solid substances in the wine. The filtered wine is diverted Under the drainage of the funnel, the water wheel is concentrated and impacted to make the water wheel rotate. The tooth plate of the water wheel is set in a concave shape. The condition of the water wheel; then the water wheel drives the filter screen to rotate slowly through the transmission box, and the filter screen is provided with sink holes for depositing solid matter, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com