Damping-force-adjustable stretching drier

A technology of stretching oven and adjusting damping, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems of large tension of strip material, increased tension of damping roller, and increased tension of traction roller, etc. The effect of winding and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

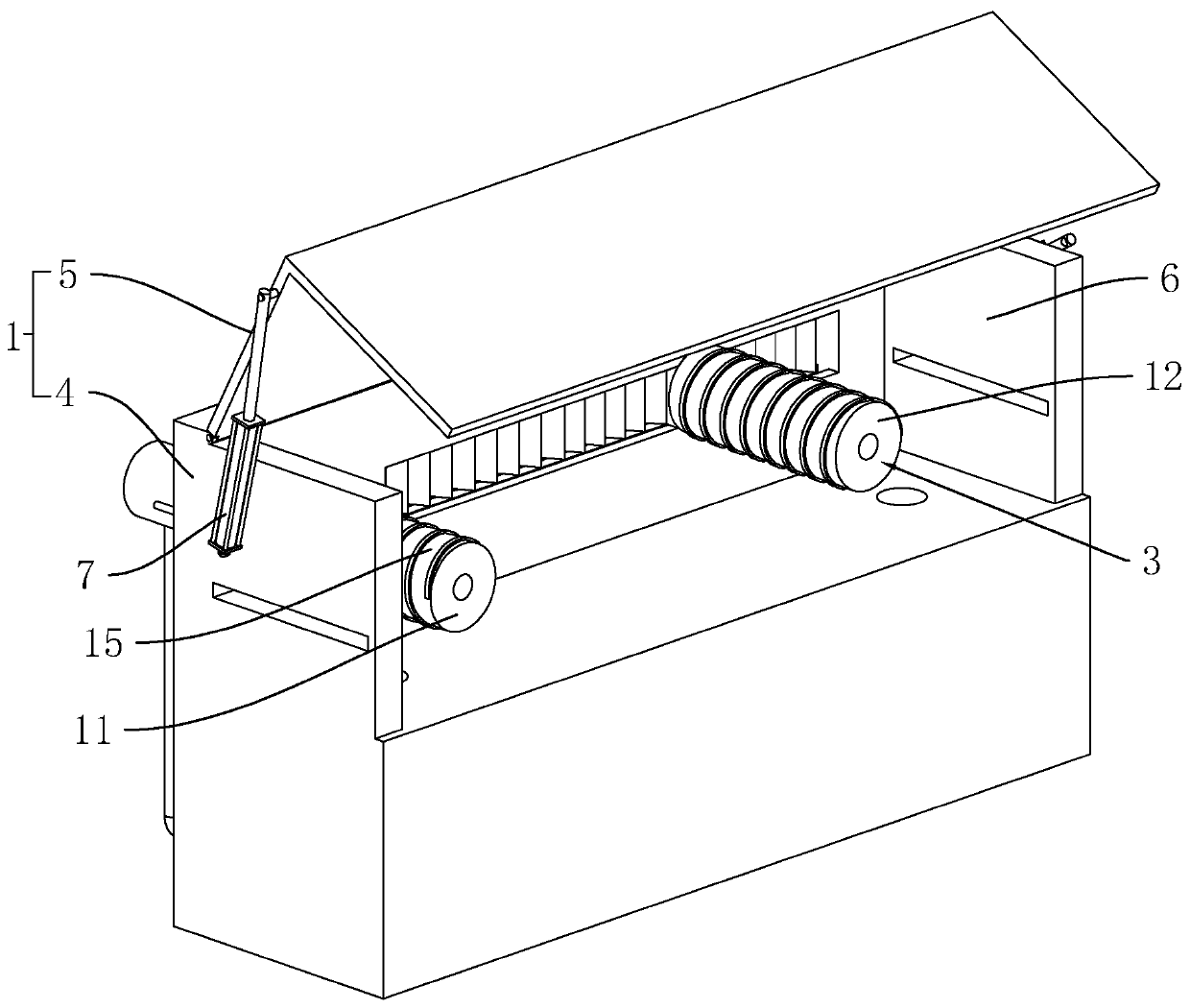

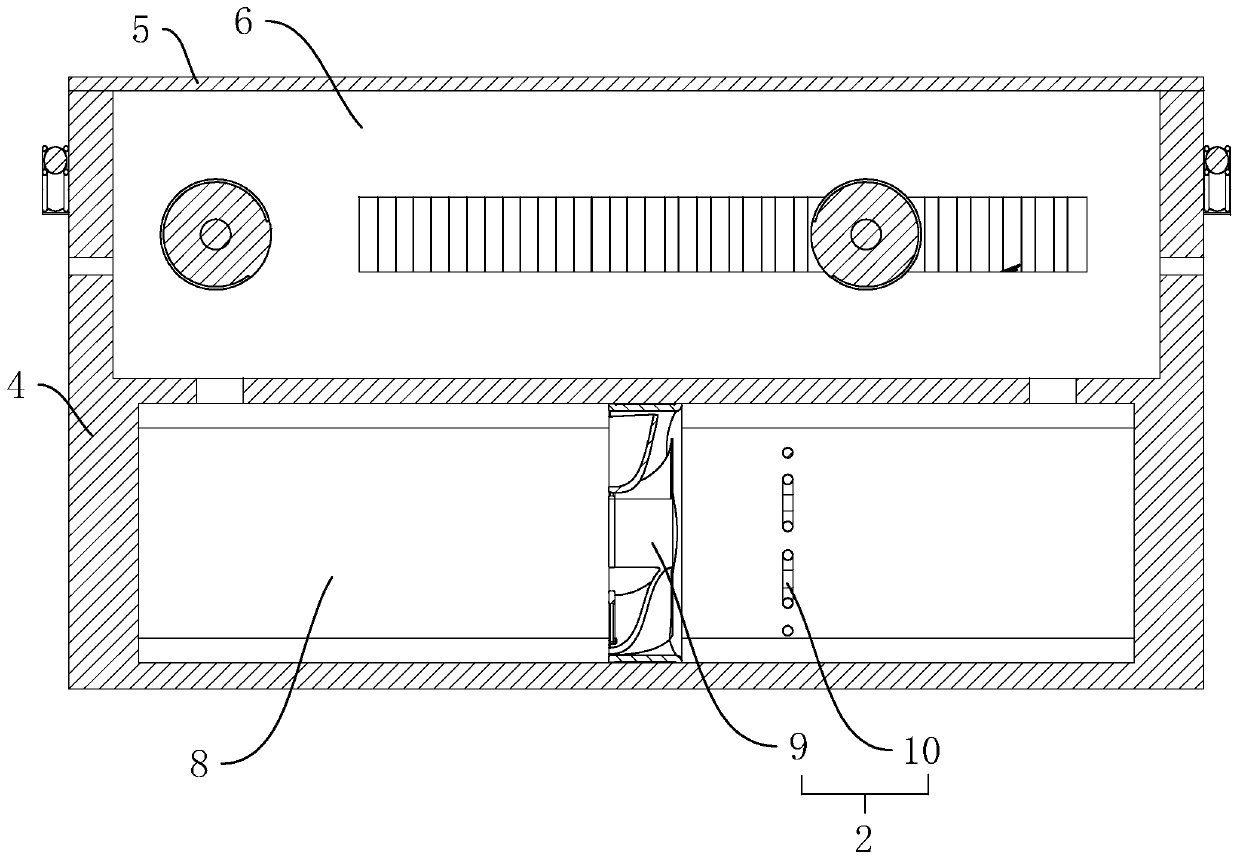

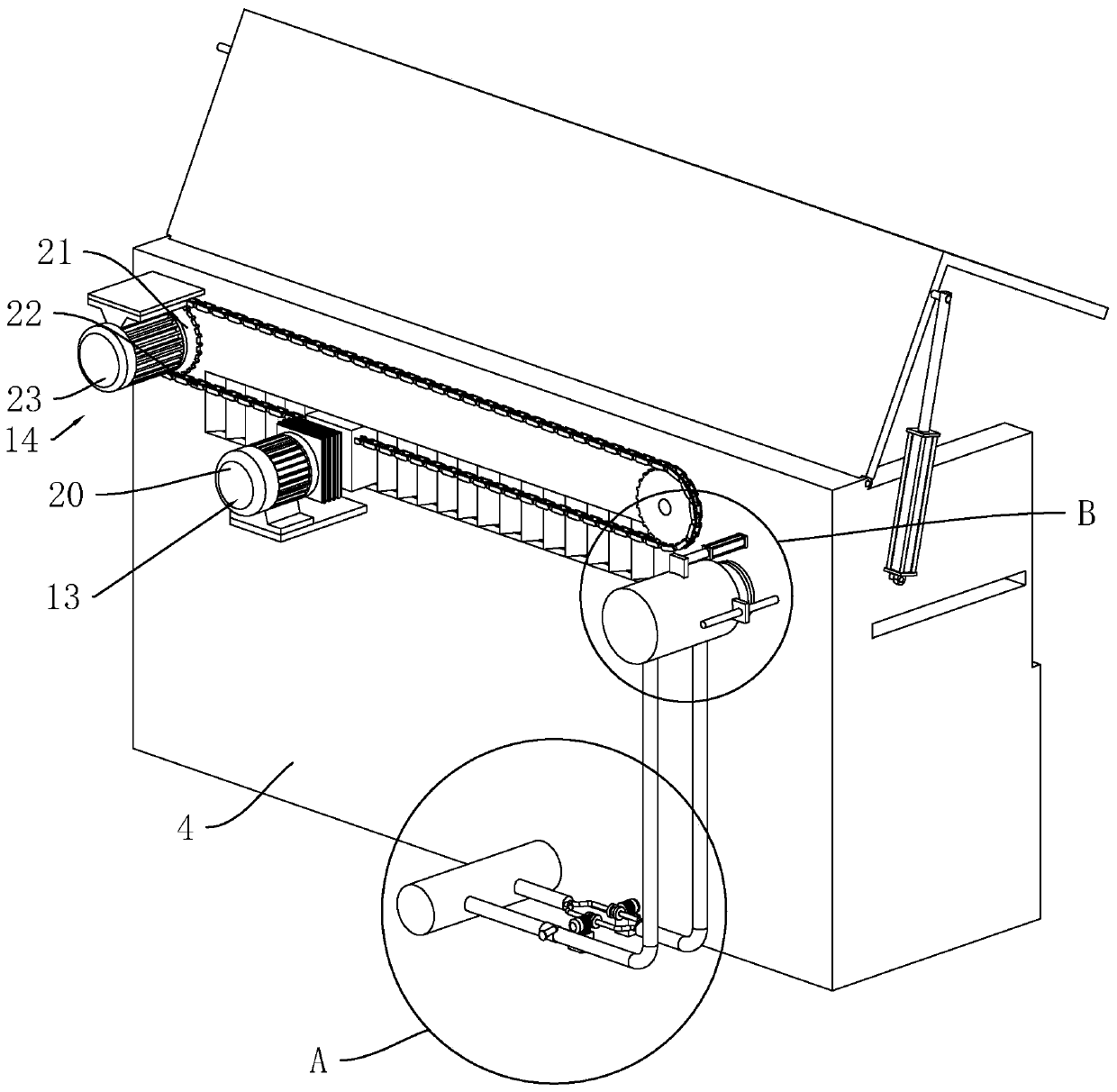

[0036] Embodiment: a kind of stretching oven with adjustable damping force, such as figure 1 with figure 2 As shown, it includes a box body 1, a heating structure 2 and a tensile structure 3. There are openings at both ends of the box body 1, and the strip-shaped material extends into the box body 1 from the opening at one end of the box body 1, then wraps around the tensile structure 3, and finally leaves the box body 1 through the outlet at the other end of the box body 1. The heating structure 2 is used to heat the strip-shaped material to soften it, and then the stretching structure 3 is used to apply tension to the strip-shaped material to elongate it and reduce its width and thickness.

[0037] Such as figure 1 As shown, the box body 1 includes a base 4 and an upper cover 5 with one end hinged to the base 4 , a rectangular cavity 6 is opened at the upper end of the base 4 , and the tensile structure 3 is located in the cavity 6 . The upper end and one side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com