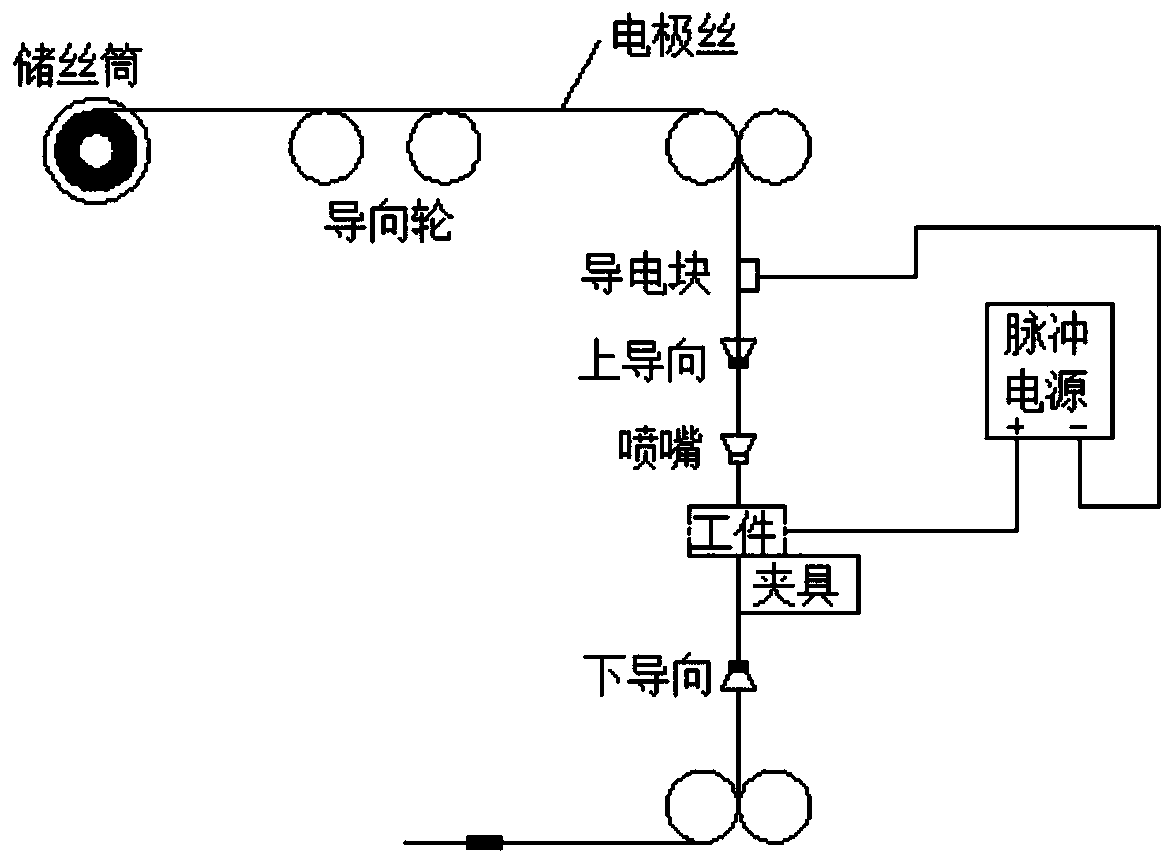

Applied to the device for photographing the discharge channel of slow-moving wire electric discharge cutting

An EDM wire and discharge channel technology, applied in accessories, color TV parts, TV system parts and other directions, can solve the problems of spark shooting interference, unclear shooting, unfavorable shooting, etc., to achieve clear shooting, avoid Flush interference, ensure efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

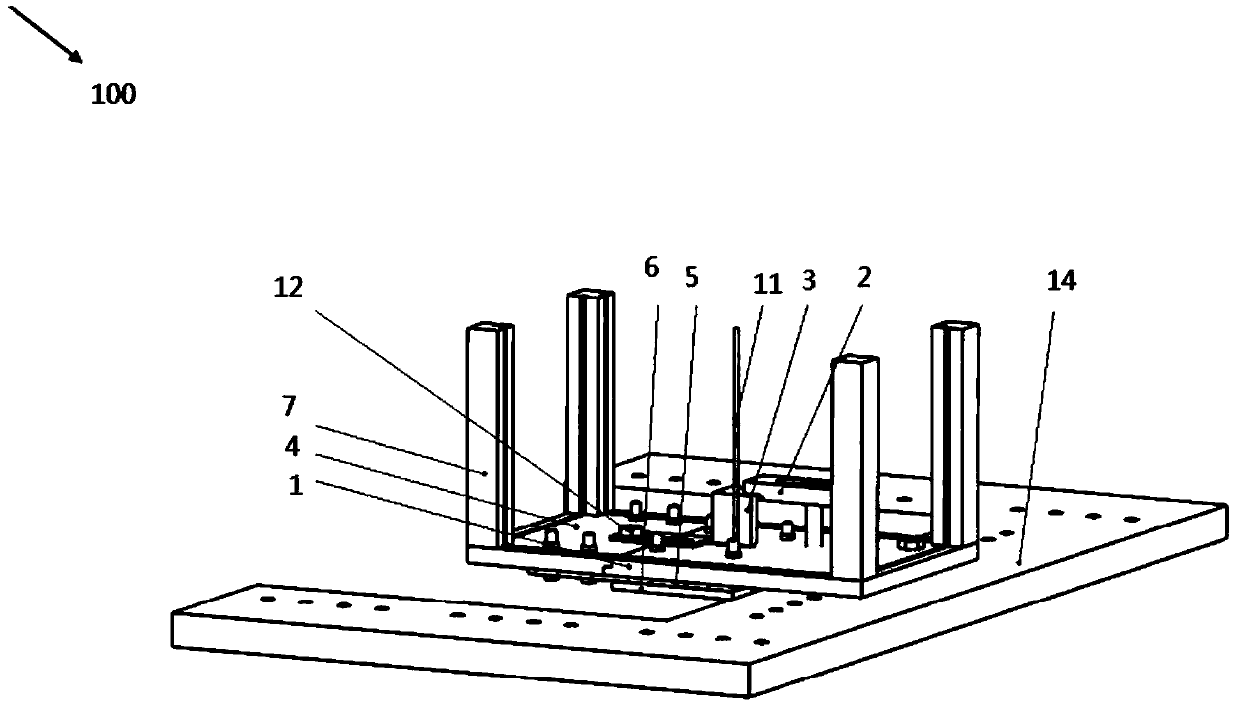

[0023] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

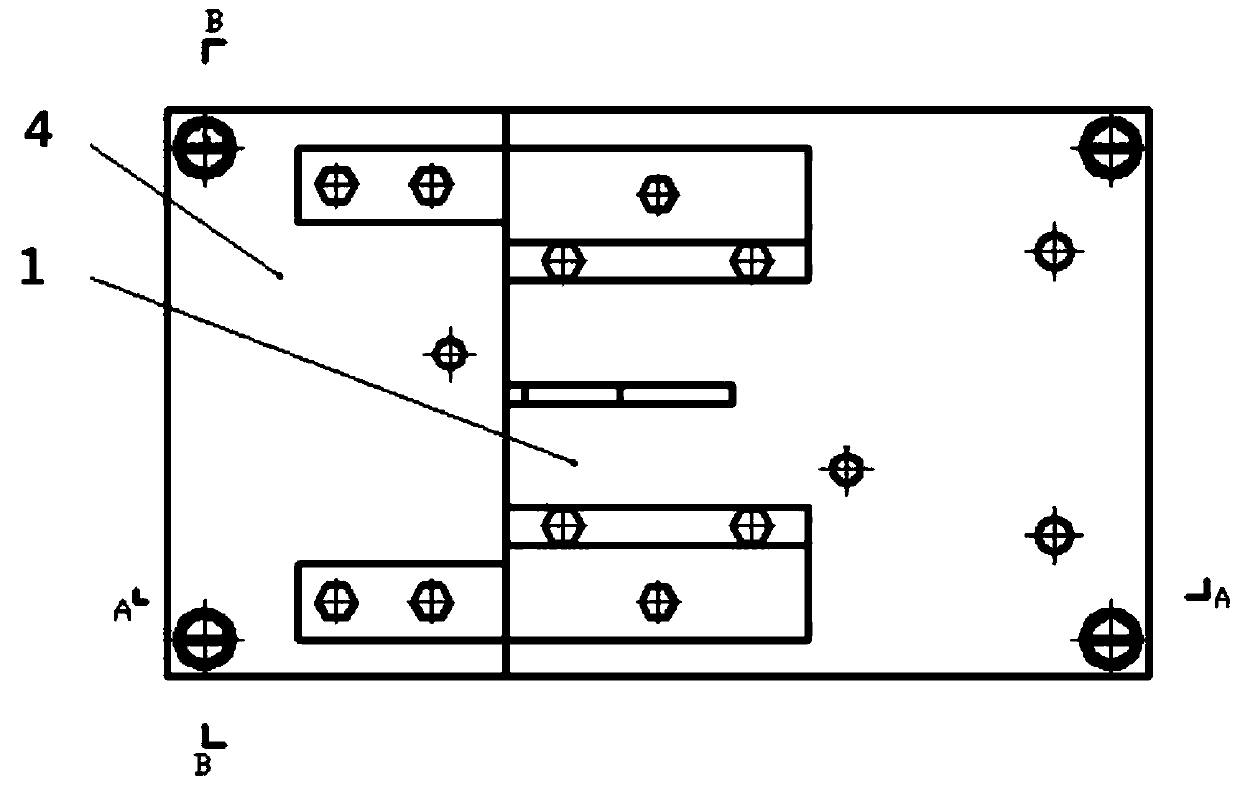

[0024] figure 2 It is a schematic diagram of the overall structure of the device used to photograph the slow-moving wire electric discharge discharge channel after the acrylic plate is pulled out in the embodiment of the present invention, image 3 It is a schematic diagram of the bottom of the device used to photograph the slow-moving wire electric discharge discharge channel in the embodiment of the present invention, Figure 4 yes image 3 The A-A section diagram, Figure 5 yes image 3 The B-B section diagram.

[0025] Such as figure 2 , image 3 , Figure 4 as well as Figure 5 As shown, the device 100 of the present embodiment for photographing slow-moving WEDM discharge channels includes a bottom plate, an adapter plate, a connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com