Ion-specific filter membrane/mesoporous silicon composite materials, nanosensors and their products and applications

A composite material and specific technology, applied in the field of ion-specific filter membrane/mesoporous silicon composite material, can solve the problems of narrow fluctuation range, insufficient sensitivity of optical sensor, and achieve controllable conditions, good possibility of clinical transformation, Mild effect of the reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Synthesis of mesoporous silica nanoparticles: 2 g of cetyltrimethylammonium chloride and 0.07 g of triethanolamine were sequentially dissolved in 20 ml of deionized water, and heated to 95° C. for 1 h under vigorous stirring. Afterwards, 1.5 ml of ethyl orthosilicate was added dropwise, and the stirring reaction was continued for 1 h. Impurities were removed by washing with methanol several times, and the product was collected by centrifugation. The collected product was extracted with 1 wt% sodium chloride methanol solution for 3 hours to wash away the template agent to obtain mesoporous silica nanoparticles.

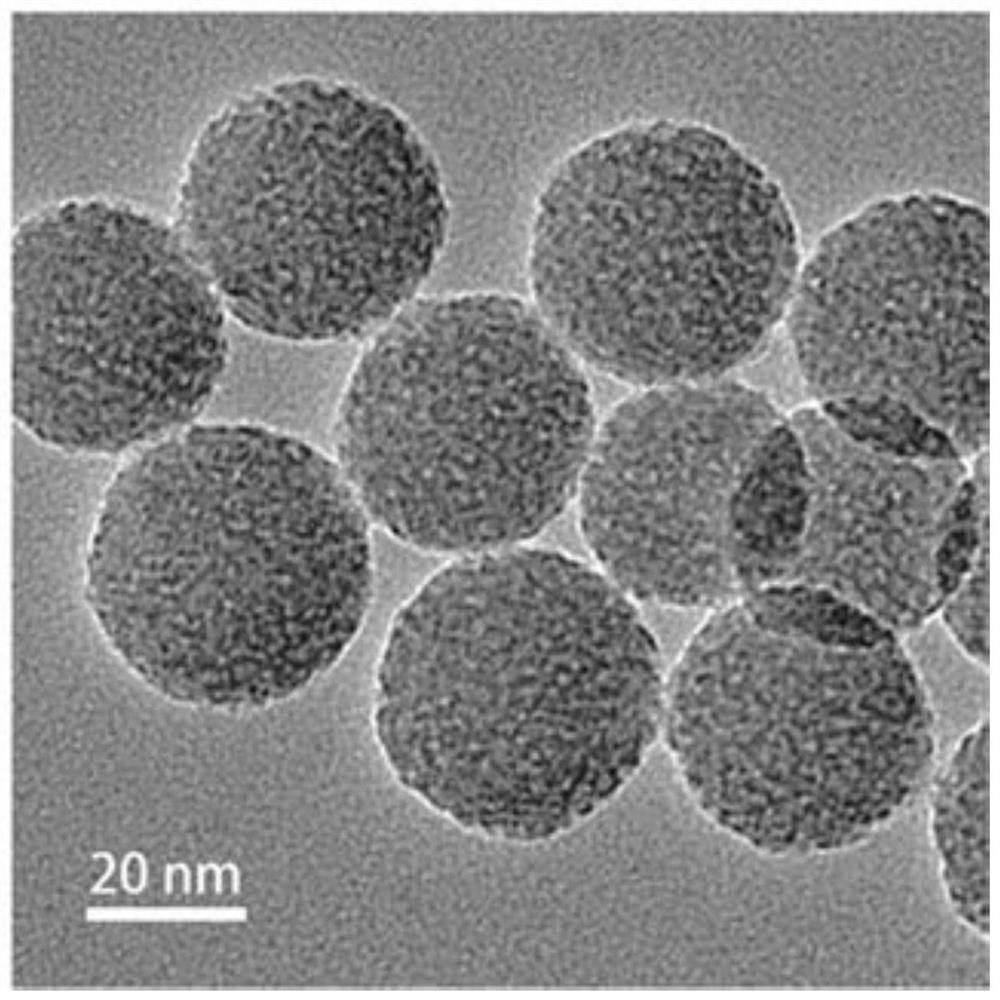

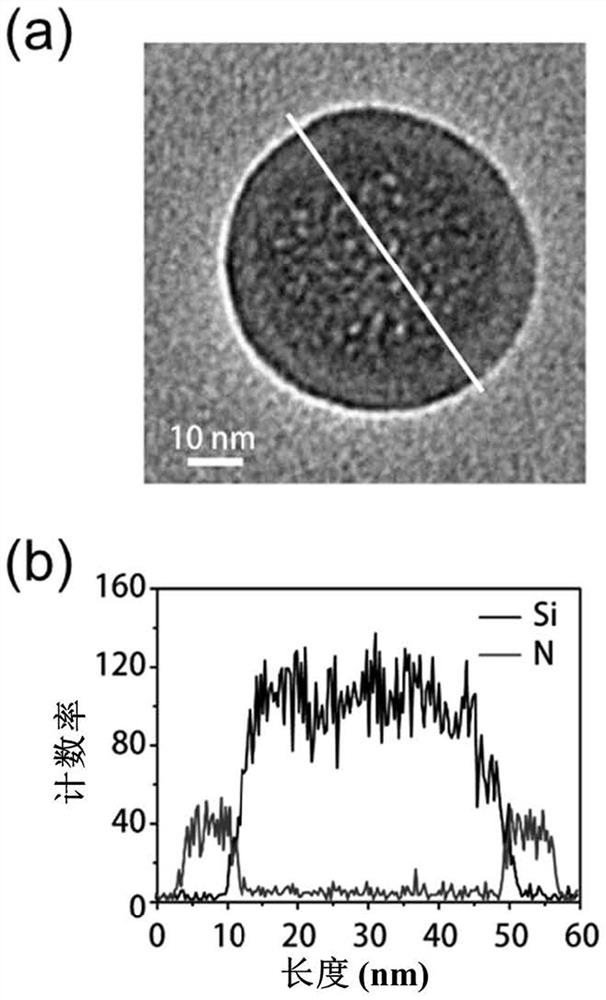

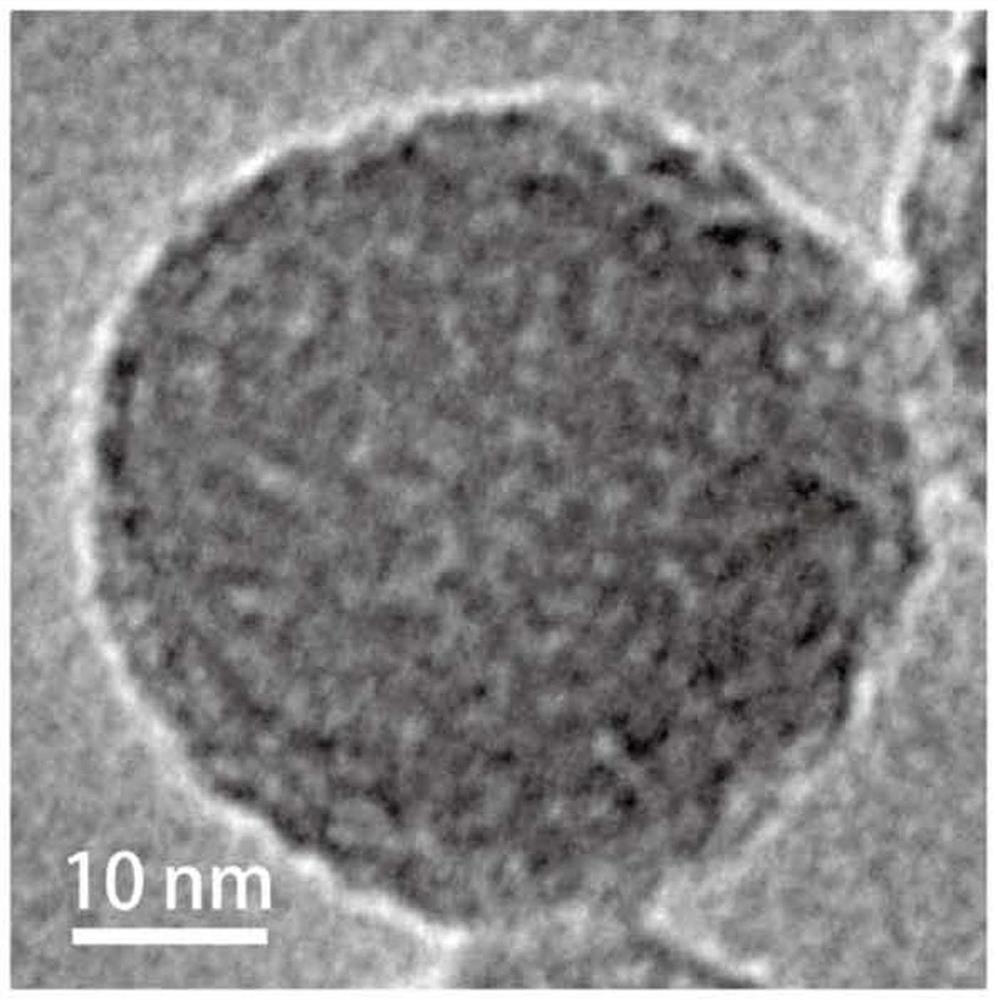

[0054] The prepared mesoporous silica nanoparticles were characterized by transmission electron microscopy, as shown in the attached figure 1 As shown, the diameter is about 30-50 nm.

[0055] (2) Synthesis of the composite material of potassium ion-specific filter membrane / mesoporous silicon: 3.4g N-benzyl salicylamide and 2.5g anhydrous potassium carbona...

Embodiment 2

[0061] (1) Synthesis of mesoporous silica nanoparticles: 2 g of cetyltrimethylammonium chloride and 0.07 g of triethanolamine were sequentially dissolved in 20 ml of deionized water, and heated to 95° C. for 1 h under vigorous stirring. Afterwards, 1.5 ml of ethyl orthosilicate was added dropwise, and the stirring reaction was continued for 1 h. Impurities were removed by washing with methanol several times, and the product was collected by centrifugation. The collected product was extracted with 1 wt% sodium chloride methanol solution for 3 hours to wash away the template agent to obtain mesoporous silica nanoparticles.

[0062](2) Synthesis of the composite material of potassium ion-specific filter membrane / mesoporous silicon: 3.4g N-benzyl salicylamide and 2.5g anhydrous potassium carbonate were added successively in 25mL anhydrous dimethylformamide and the temperature was raised to 90 ℃, then added 2.9g 1,1,1-tris(p-toluenesulfonyloxy-methyl)ethane and 0.3mL 2-aminotereph...

Embodiment 3

[0066] (1) Synthesis of mesoporous silica nanoparticles: 2 g of cetyltrimethylammonium chloride and 0.07 g of triethanolamine were sequentially dissolved in 20 ml of deionized water, and heated to 95° C. for 1 h under vigorous stirring. Afterwards, 1.5 ml of ethyl orthosilicate was added dropwise, and the stirring reaction was continued for 1 h. Impurities were removed by washing with methanol several times, and the product was collected by centrifugation. The collected product was extracted with 1 wt% sodium chloride methanol solution for 3 hours to wash away the template agent to obtain mesoporous silica nanoparticles.

[0067] (2) Synthesis of the composite material of potassium ion-specific filter membrane / mesoporous silicon: 3.4g N-benzyl salicylamide and 2.5g anhydrous potassium carbonate were added successively in 25mL anhydrous dimethylformamide and the temperature was raised to 90 ℃, then added 2.9g 1,1,1-tris(p-toluenesulfonyloxy-methyl)ethane and 0.3mL 2-aminoterep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com