A negative pressure thawing device and method thereof

A technology of negative pressure and negative pressure fan, which is applied in the direction of freezing/cooling to preserve meat/fish, etc., can solve the problems of high energy consumption, affecting the thawing speed and thawing consistency, and inconsistent thawing time, so as to improve the thawing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

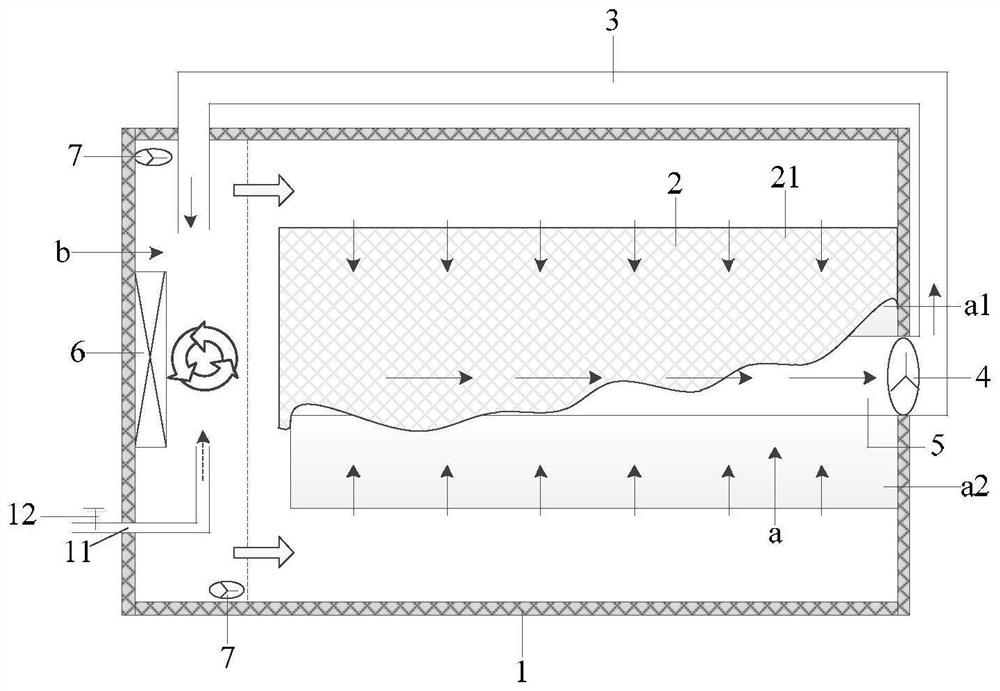

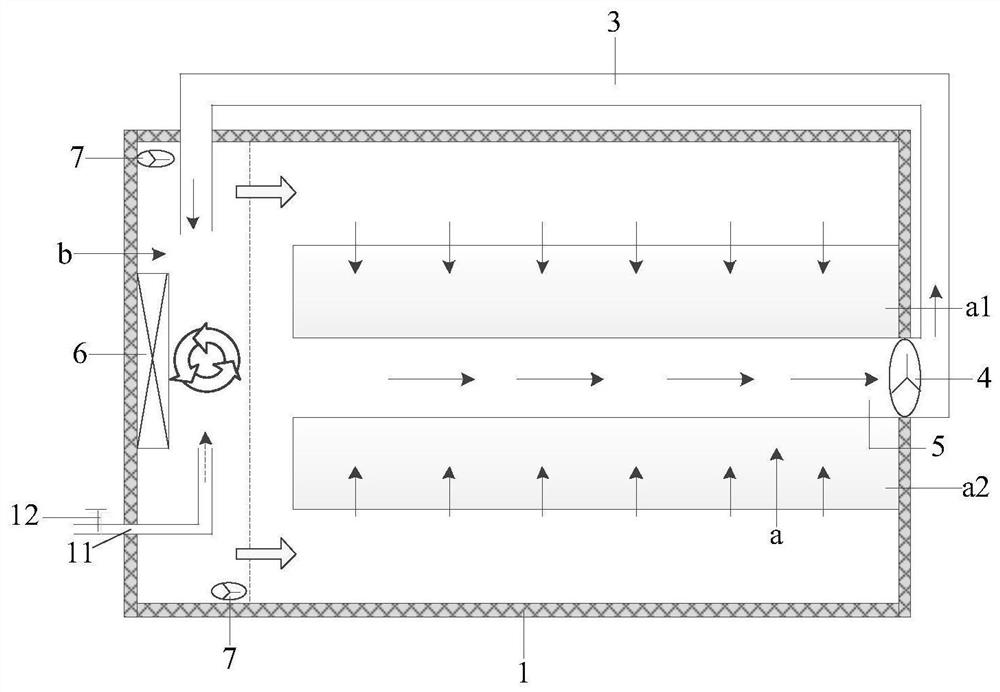

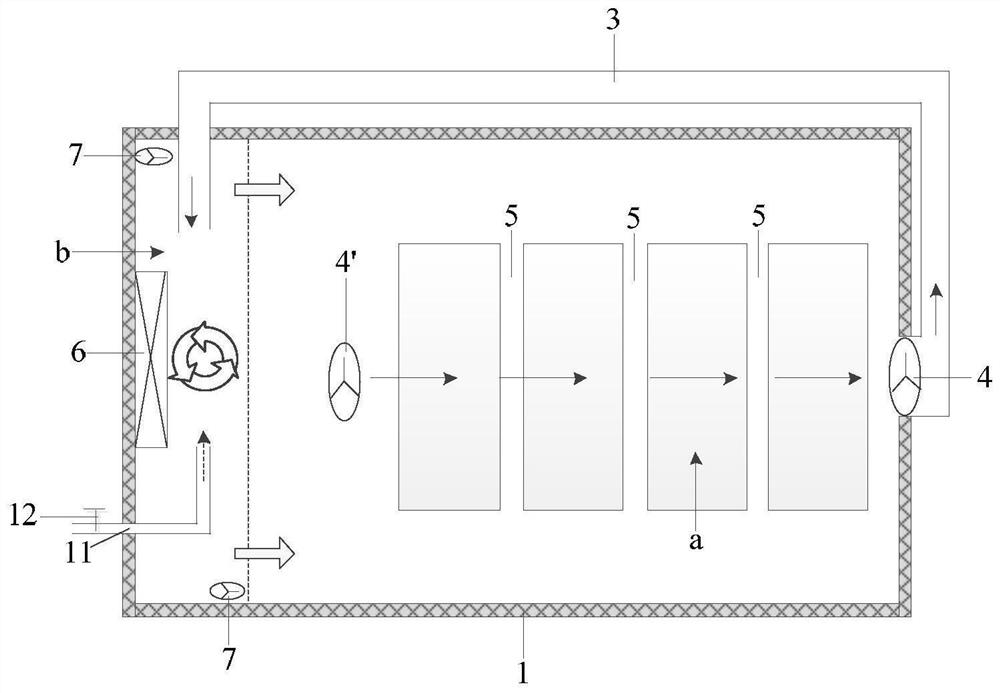

[0032] Such as figure 1 As shown, the negative pressure thawing device of this embodiment includes a box body 1, and a barrier 2 is arranged in the box body 1, and the inner space of the box body 1 is divided into a thawing area a and a warming area b, and the thawing area a It is connected with the return temperature area b through the return air pipeline 3, and the negative pressure fan 4 is arranged in the return air pipeline 3, and the defrosting area a is used for stacking the products to be unfrozen. The circulation hole 21 has a channel 5 connected with the return air pipeline 3 inside the defrosting area a, and the cold air generating component and the hot steam generating component are communicated in the returning temperature area b. The setting of the barrier 2 can isolate the products to be thawed, and realize the separation of cold and heat in the inner space of the box body 1. Two times of cold and heat exchanges, one is in the low-temperature and high-humidity a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com