Preparation method of porosity controllable graphene modified silicon-carbon composite material

A silicon-carbon composite material, graphene modification technology, applied in nanotechnology, electrical components, electrochemical generators for materials and surface science, etc., can solve the problem of low specific surface area, high electrical conductivity, first efficiency cycle maintenance The problem of high rate, low specific surface area, high electrical conductivity, and excellent point-to-point conductivity are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

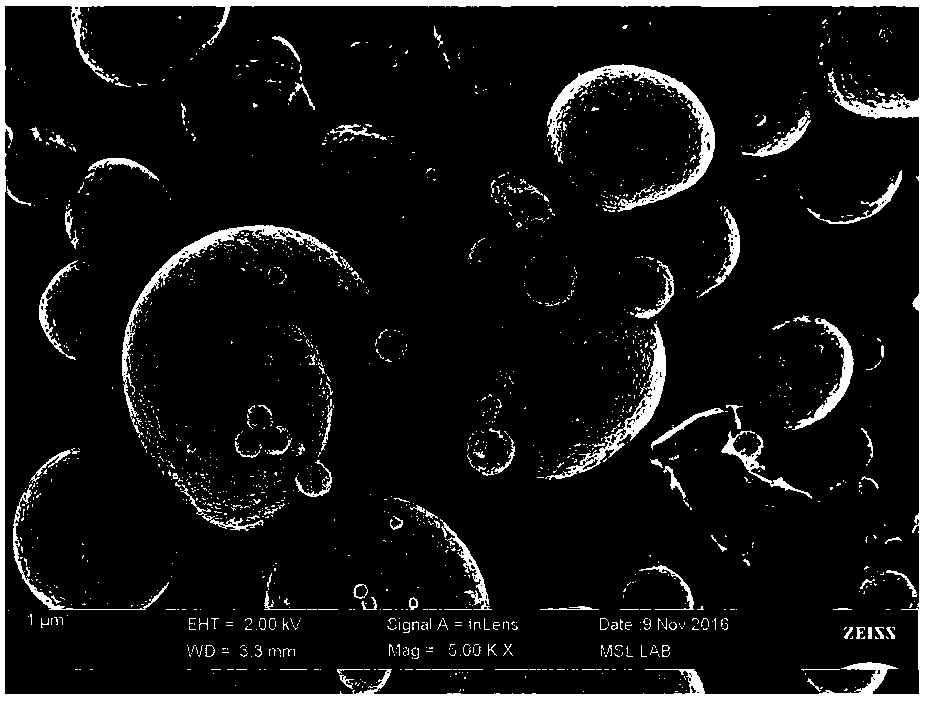

[0037] Embodiment 1, the present embodiment is the preparation of the graphene-modified nano silicon powder of particle diameter 10-60nm porosity 45%:

[0038] Step 1. Pre-disperse coarse silicon powder: Add 300g of polymer copolymer dispersant to the mixed solvent of 10kg of deionized water and 9kg of absolute ethanol, stir until completely dissolved; then add 1kg of high-purity metal silicon with a particle size of 5um powder, and high-speed stirring to disperse evenly to obtain a slurry with a solid content of 5% coarse silicon powder.

[0039]Step 2. Preparation of nano-silicon slurry: pass nitrogen protection into the dispersion tank, add 0.1mm zirconia balls to the ball mill tank according to the ball-to-material ratio of 100:1, set the line speed to 800m / s and the feed pump pressure to 0.2MPa , start circulating ball milling, and obtain uniformly dispersed nano-silicon slurry after ball milling for 8 hours.

[0040] Step 3, preparing nano-silicon powder: spray-drying t...

Embodiment 2

[0044] Embodiment 2, the present embodiment is the preparation of the graphene-modified nano silicon powder of particle diameter 50-100nm porosity 30%:

[0045] Step 1. Pre-disperse coarse silicon powder: Add 250g of polymer copolymer dispersant and 50g of ascorbic acid to 19kg of absolute ethanol, then add 1kg of high-purity metal silicon powder with a particle size of 5um, stir at high speed and disperse evenly to obtain a concentration of 10% The pre-dispersed coarse silica powder slurry.

[0046] Step 2. Prepare nano-silicon slurry: pass nitrogen protection into the dispersion tank, add 0.2mm zirconia balls to the ball mill tank according to the ball-to-material ratio of 100:1, set the line speed to 800m / s and the feed pump pressure to 0.2MPa , start circulating ball milling, and obtain uniformly dispersed nano-silicon slurry after ball milling for 7 hours.

[0047] Step 3, preparing nano-silicon powder: spray-drying the nano-silicon slurry obtained in step 2 to obtain na...

Embodiment 3

[0051] Embodiment 3, the present embodiment is the preparation of the graphene-modified nano silicon powder of particle diameter 80-200nm purity 20%:

[0052] Step 1. Pre-disperse coarse silicon powder: add 200g of polymer copolymer dispersant and 50g of ascorbic acid until 15kg of ethylene glycol dissolves completely, then add 1kg of high-purity metal silicon powder with a particle size of 5um, stir at high speed and disperse evenly to obtain 10 % concentration of pre-dispersed coarse silicon powder slurry.

[0053] Step 2. Preparation of nano-silicon slurry: pass nitrogen protection into the dispersion tank, add 0.3mm zirconia balls into the ball mill tank according to the ball-to-material ratio of 100:1, set the line speed to 600m / s and the feed pump pressure to 0.2MPa , start circulating ball milling, and obtain uniformly dispersed nano-silicon slurry after ball milling for 7 hours.

[0054] Step 3, preparing nano-silicon powder: spray-drying the nano-silicon slurry obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com