A device and method for refining molten steel by full bottom blowing ladle

A ladle refining and ladle technology, which is used in manufacturing tools, casting melt containers, casting equipment, etc., can solve problems such as inability to efficiently capture and remove inclusions, inability to stir molten steel well, and lower argon blowing efficiency. The effect of speeding up the production efficiency of enterprises, improving the quality of steel products, and reducing the area of slag holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

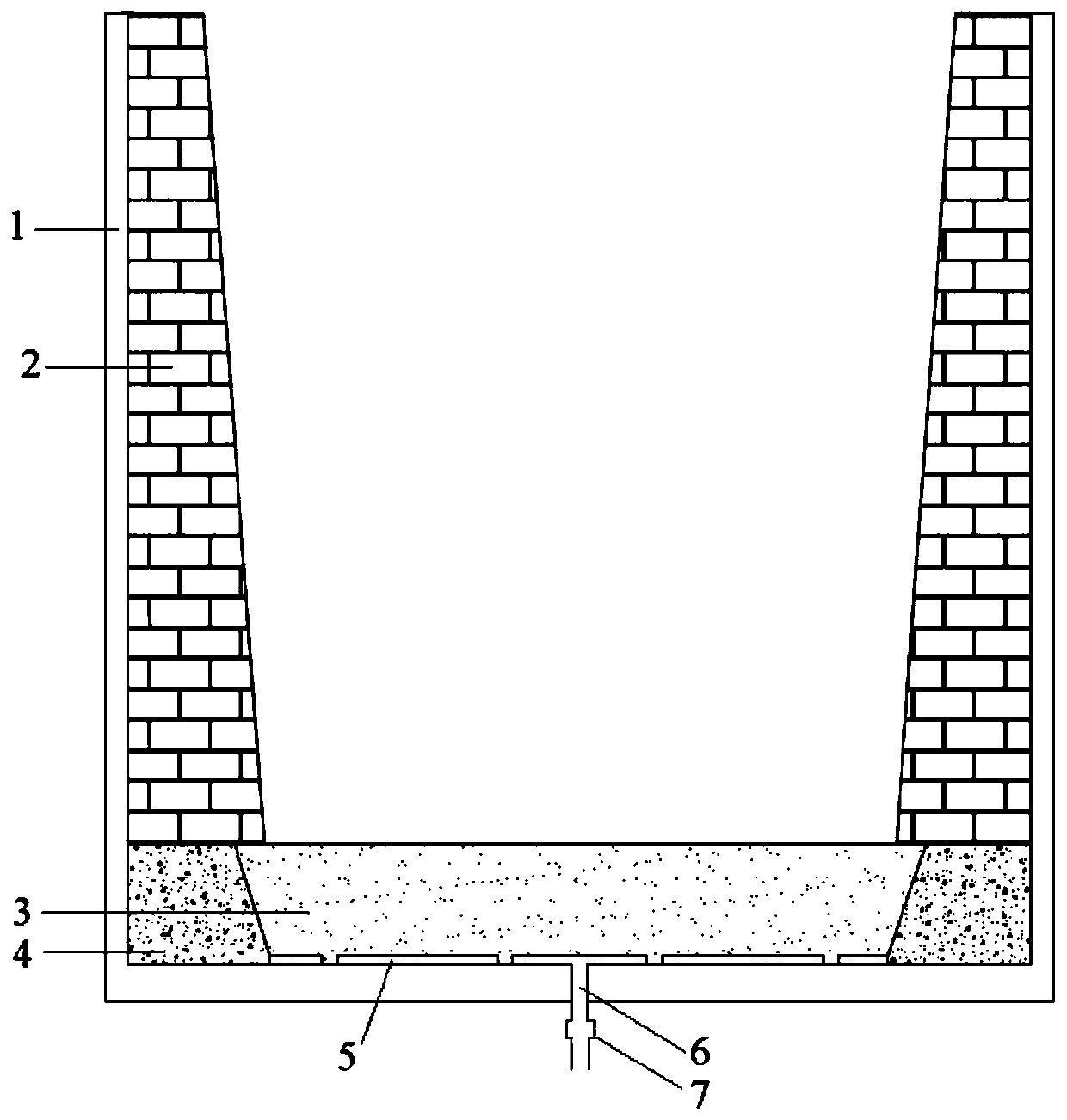

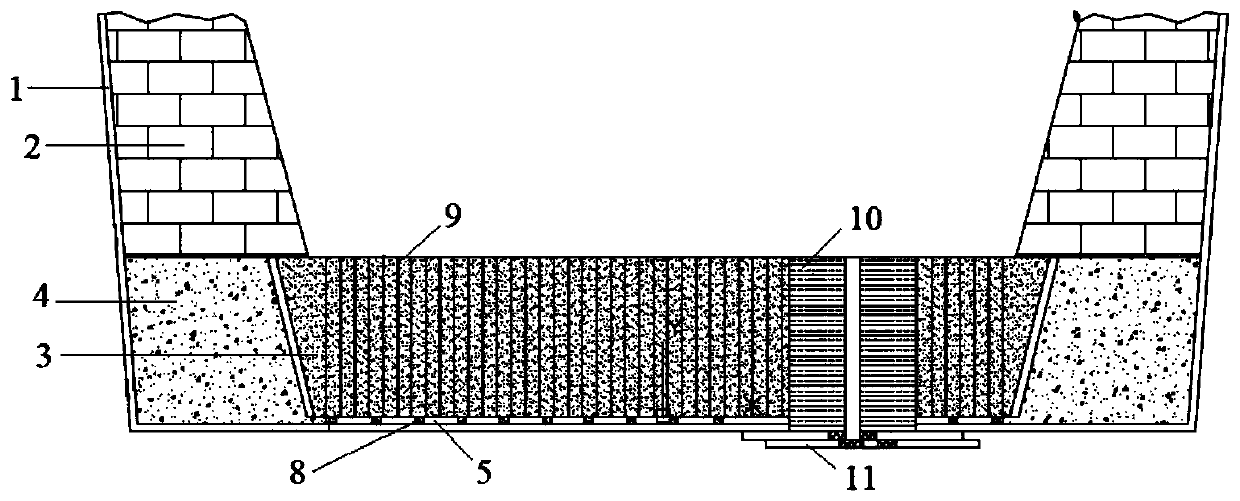

[0029] Such as figure 1 , 2 As shown, the present embodiment provides a device for refining molten steel by blowing a ladle at the bottom, including a ladle 1 for refining molten steel. The ladle 1 includes a ladle wall and a ladle bottom, and the ladle wall is formed by laying bricks 2 of refractory materials The bottom of the ladle is located below the molten steel, and a full-bottom blowing and ventilating element 3 is embedded in the bottom of the ladle. With steel sleeve. A tamping material 4 is filled between the refractory brickwork 2 and the full-bottom blowing and ventilating element 3, and the tamping chamber material 4 makes the position of the full-bottom blowing and ventilating element 3 in the ladle 1 more fixed and will not move.

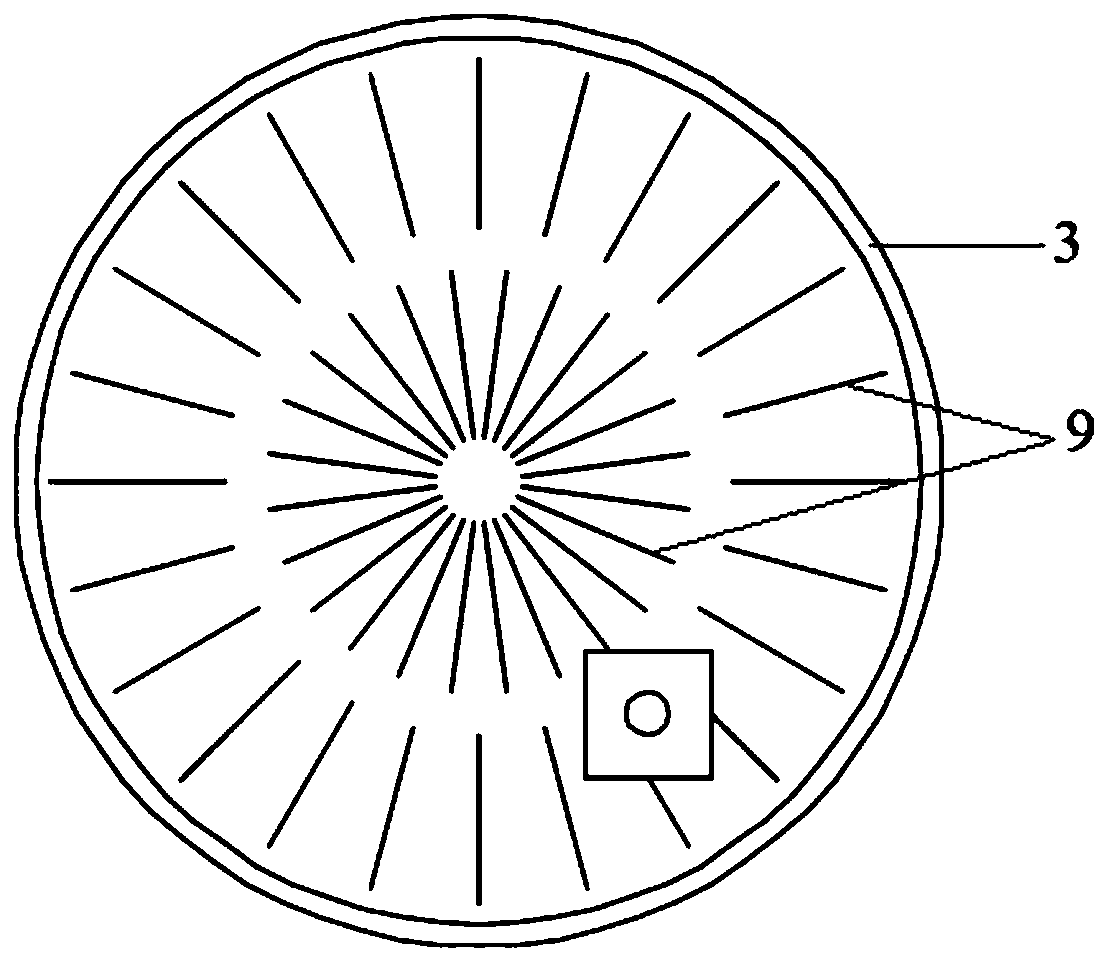

[0030] The full-bottom air-ventilating element 3 includes a frustum-shaped element body and legs 8, and 16 legs 8 are evenly arranged on the bottom of the element body, sintered with the element body, and formed between the full-bot...

Embodiment 2

[0037] This embodiment adopts as figure 1 The device shown is used for refining molten steel. In this embodiment, a cylindrical full-bottom blowing and ventilating element 3 is embedded in the bottom of the ladle. within the area of 81%.

[0038] Such as Figure 4 As shown, the slits 9 on the full-bottom air-ventilating element 3 are arranged in the form of annular seams throughout the full-bottom air-ventilating element 3, and the width of the slits 9 is 0.05mm.

Embodiment 3

[0040] This embodiment adopts as figure 1 The shown device carries out molten steel refining, and the height of supporting leg 8 is 1mm in the present embodiment, and the whole bottom air-blowing element 3 is arranged on the radius of 25% in the area centered on the center of circle at the bottom of the ladle.

[0041] Such as Figure 5 As shown, the slits 9 on the full-bottom air-ventilating element 3 are set in a straight slit pattern and run through the full-bottom air-ventilating element 3, and the width of the slits 9 is 0.1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com