High-density water-based drilling fluid and preparation method thereof

A water-based drilling fluid and high-density technology, applied in the field of oilfield drilling fluids, can solve the problems of unknown rock-carrying effect of high-density drill cuttings, achieve good settlement stability, improve drilling efficiency, and avoid the effects of sticking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

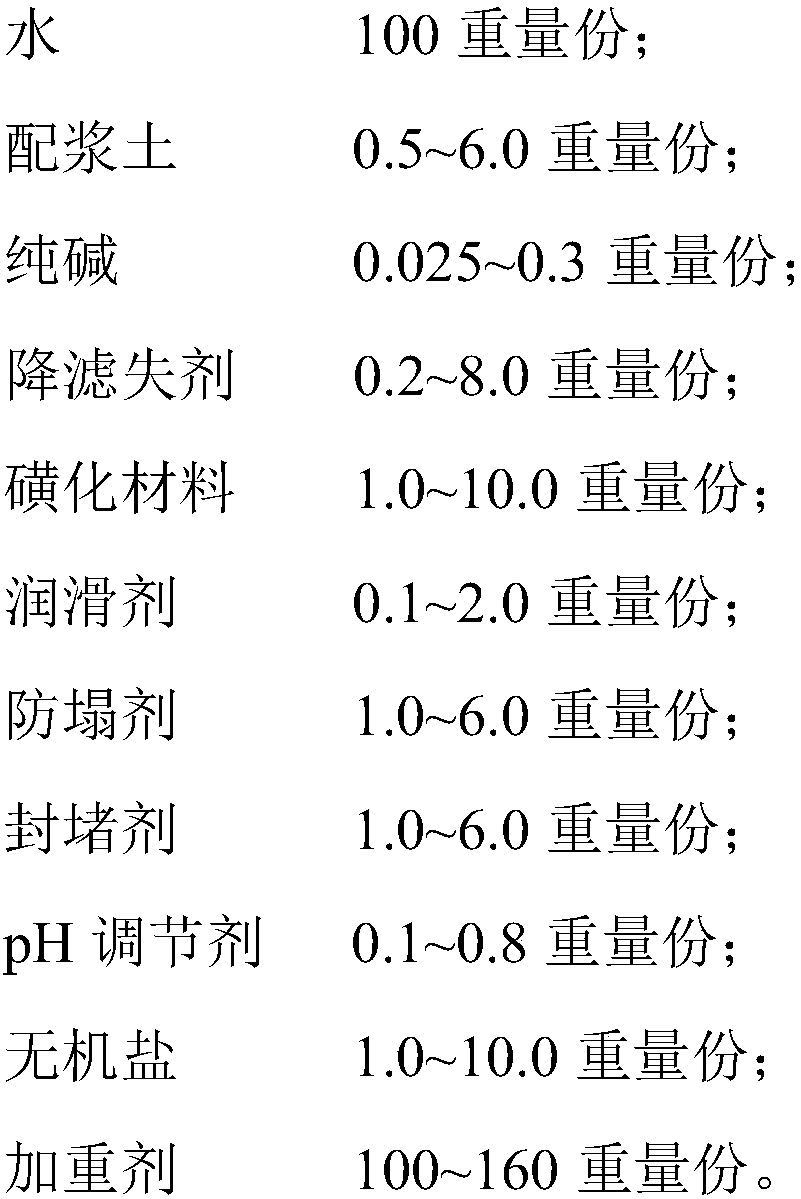

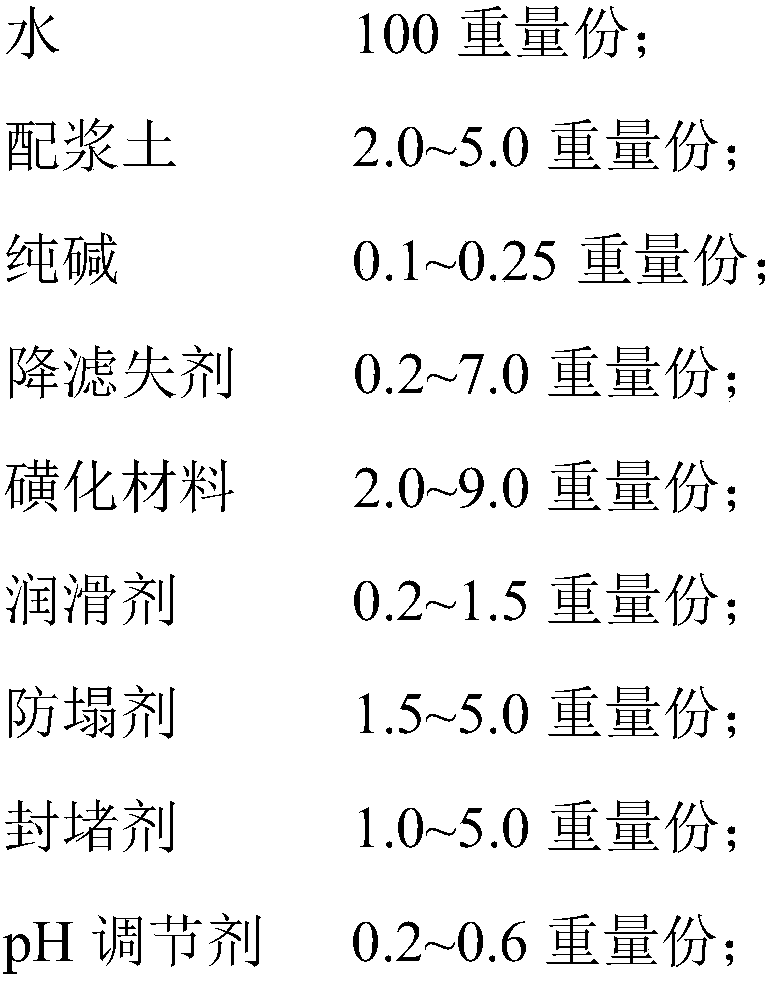

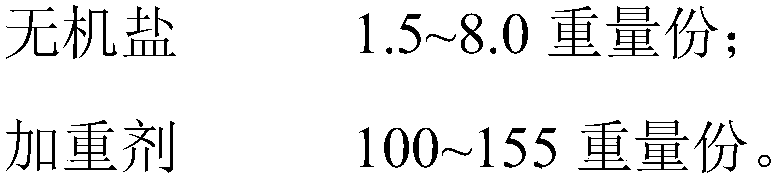

Method used

Image

Examples

Embodiment 1

[0040] This embodiment relates to a high-density drilling fluid suitable for safe drilling in diabase formations. The components include 100 parts of water, 2.5 parts of calcium-based bentonite, and 0.125 parts of Na 2 CO 3, 1.5 parts of LV-PAC, 1.0 parts of SMC, 1.0 parts of SMP-2, 1.0 parts of SPNH, 0.5 parts of graphite, 2.5 parts of emulsified pitch FF-III, 1.5 parts of superfine calcium carbonate, 0.2 parts of NaOH, 2.0 parts of NaCl, 103 parts Barite. The ultrafine calcium carbonate particle size is 20-50 μm. All components are commercially available products.

[0041] The concrete preparation method of this embodiment is: at first 0.125 parts of Na 2 CO 3 Dissolve in 100 parts of water, add 2.5 parts of calcium-based bentonite, after hydration, add 1.5 parts of LV-PAC, 1.0 parts of SMC, 1.0 parts of SMP-2, 1.0 parts of SPNH, 0.5 parts of graphite, 2.5 parts of emulsified asphalt FF-III , 1.5 parts of superfine calcium carbonate, 0.2 parts of NaOH and 2.0 parts of N...

Embodiment 2

[0046] This embodiment relates to a high-density drilling fluid suitable for safe drilling in diabase formations. The components include 100 parts of water, 2.5 parts of calcium-based sodium bentonite, and 0.125 parts of Na 2 CO 3 , 2.0 parts of LV-CMC, 1.5 parts of SMC, 1.0 parts of SMP-2, 2.0 parts of SPNH, 0.5 parts of graphite, 2.0 parts of emulsified pitch FF-III, 1.5 parts of butyl rubber, 0.2 parts of NaOH, 2.0 parts of NaCl, 115 parts by weight spar. The particle size of butyl rubber is 40-80 μm. All components are commercially available products.

[0047] The concrete preparation method of this embodiment is: at first 0.125 parts of Na 2 CO 3 Dissolve in 100 parts of water, add 2.5 parts of calcium-based sodium bentonite, after hydration, add 2.0 parts of LV-CMC, 1.5 parts of SMC, 1.0 parts of SMP-2, 2.0 parts of SPNH, 0.5 parts of graphite, 2.0 parts of emulsified asphalt FF -III. Add 1.5 parts of butyl rubber, 0.2 parts of NaOH and 2.0 parts of NaCl into the so...

Embodiment 3

[0052] This embodiment relates to a high-density drilling fluid suitable for safe drilling in diabase formations. The components include 100 parts of water, 3.0 parts of sodium bentonite, and 0.125 parts of Na 2 CO 3 , 0.6 parts of HV-PAC, 1.5 parts of SMC, 1.5 parts of SMP-2, 1.5 parts of SPNH, 1.2 parts of graphite, 2.5 parts of emulsified pitch FF-III, 1.5 parts of asbestos fiber, 0.2 parts of NaOH, 3.0 parts of KCl, 135 parts of recrystallization stone. The length of asbestos fiber particles is 20-60 μm, and the diameter is 15-30 μm. All components are commercially available products.

[0053] The concrete preparation method of this embodiment is: at first 0.125 parts of Na 2 CO 3 Dissolve in 100 parts of water, add 3.0 parts of sodium bentonite, after hydration, add 0.6 parts of HV-PAC, 1.5 parts of SMC, 1.5 parts of SMP-2, 1.5 parts of SPNH, 1.2 parts of graphite, 2.5 parts of emulsified pitch FF-III, Add 1.5 parts of asbestos fiber, 0.2 parts of NaOH and 3.0 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com