Water mobile-type slurry treatment equipment and treatment process

A treatment device and mobile technology, applied in the direction of water/sludge/sewage treatment, sludge treatment, water/sewage multi-stage treatment, etc., can solve the problem of transportation costs, high comprehensive labor costs, inconvenience at the construction site, centrifugal dehydration Problems such as high energy consumption can solve the problem of mud treatment, the effect of weight reduction is remarkable, and the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

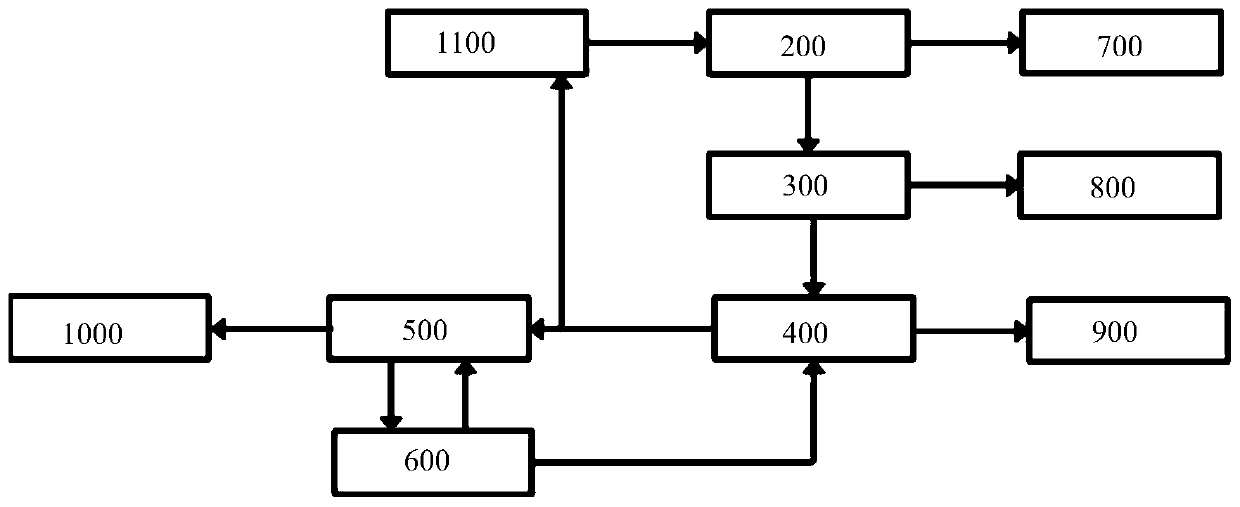

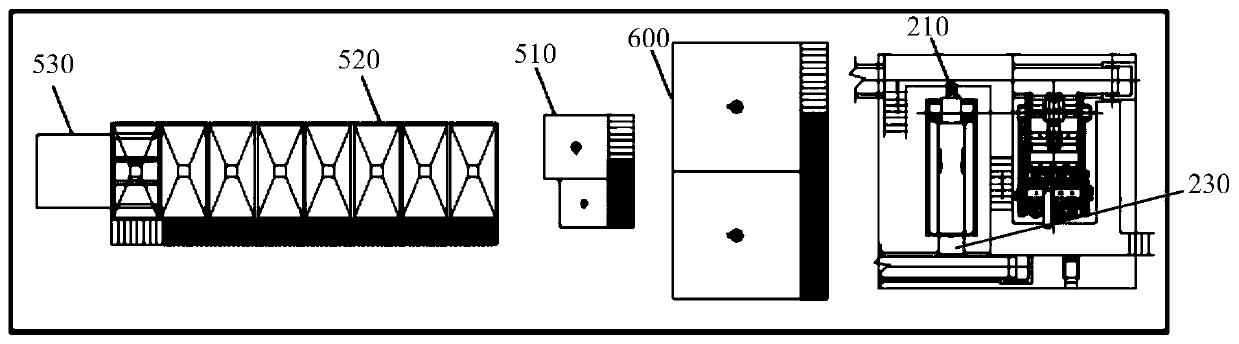

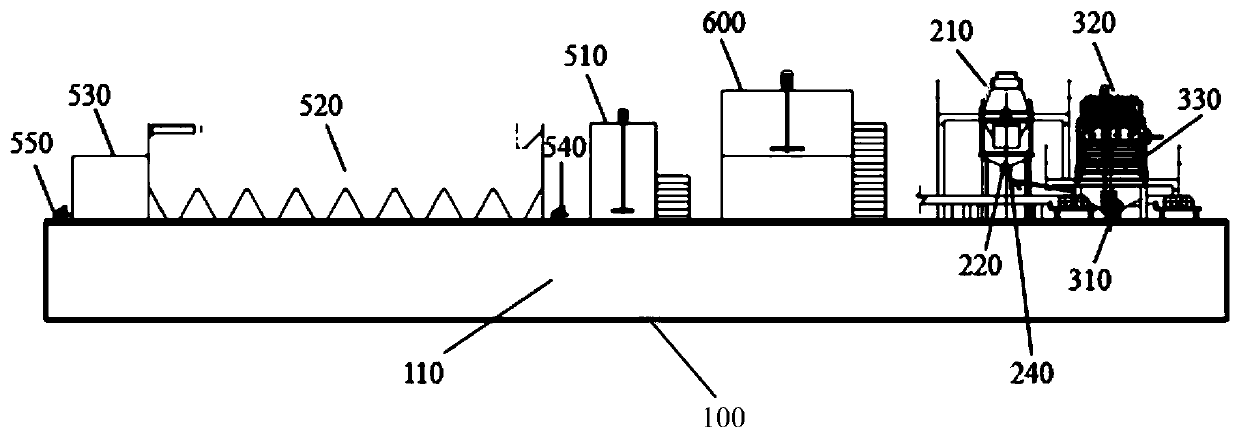

[0034] figure 1 It is a process flow diagram of the present invention. figure 2 It is a schematic top view of the first buoyancy platform of the present invention. image 3 It is a schematic plan view of the first buoyancy platform of the present invention. Figure 4 It is a schematic top view of the second buoyancy platform of the invention. Figure 5 It is a schematic plan view of the second buoyancy platform of the invention.

[0035] Such as Figure 1 to Figure 5 As shown, a water mobile mud treatment device includes: buoyancy platform 100, impurity removal system 200, sand removal system 300, dehydration system 400, tail water treatment system 500, drug dispensing system 600, solid residue recovery device 700, waste residue receiving device 800, the mud cake receiving device 900 and the tail water standard discharge device 1000, the impurity removal system 200, the sand removal system 300, the dehydration system 400, the tail water treatment system 500 and the dispen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com