Three-dimensional ribbed pipe machining cutter bar positioning device with buffer structure

A buffer structure and positioning device technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of applicability and practicability limitations, affecting processing efficiency, low heat exchange efficiency, etc., and achieve practicality Good, guaranteed processing quality, strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

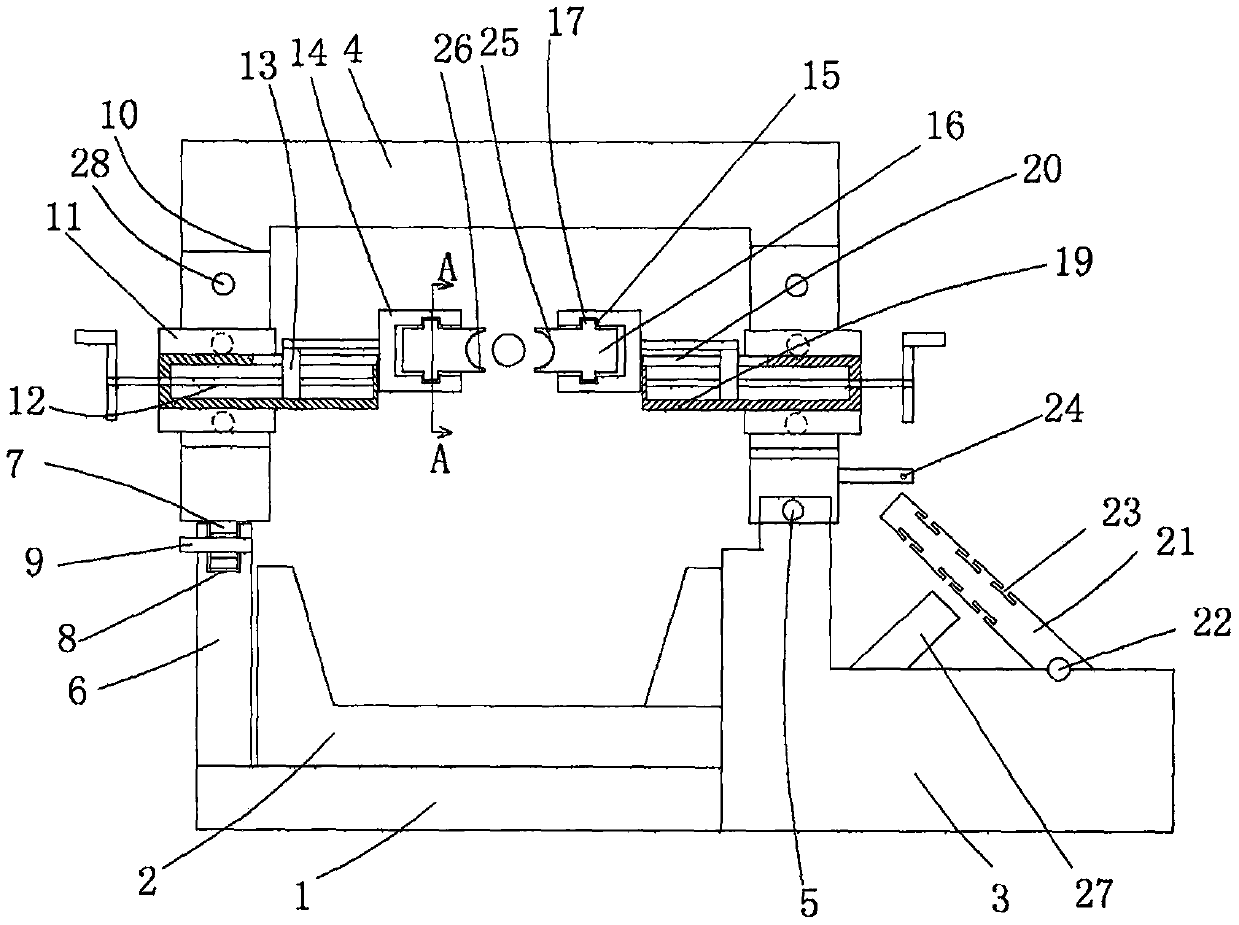

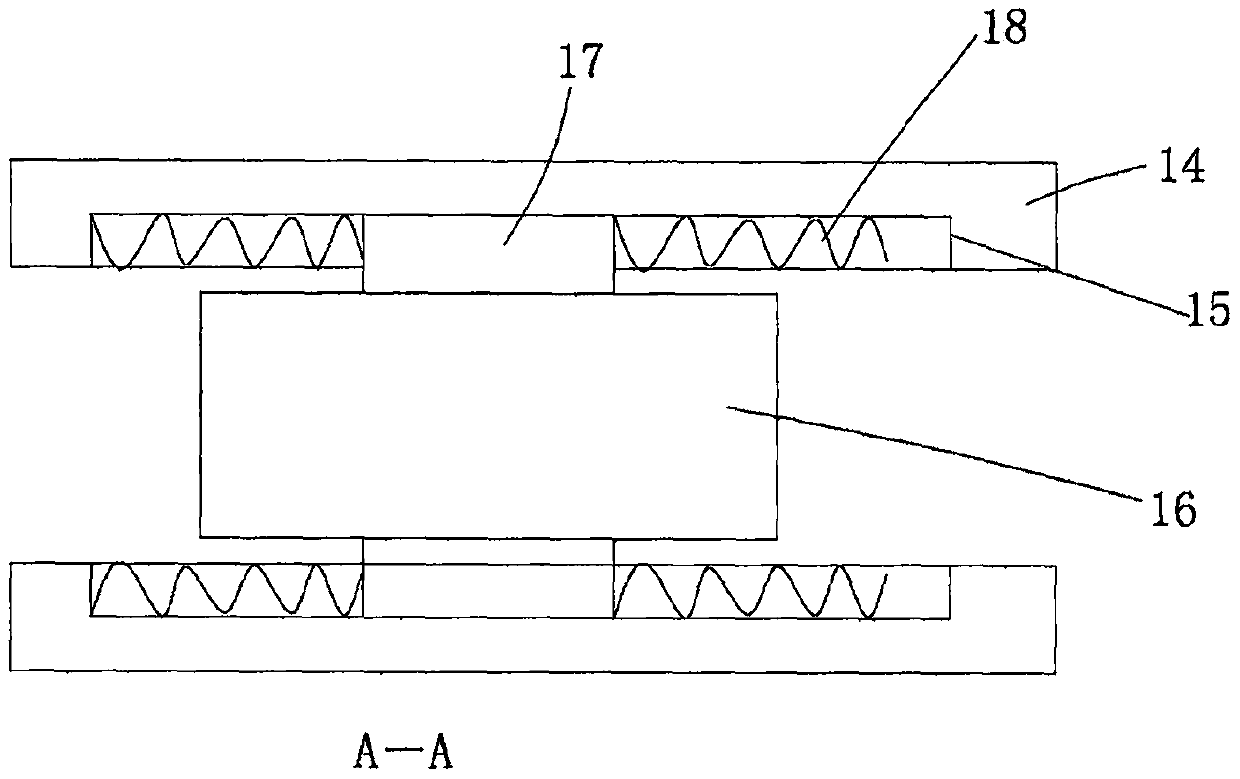

[0016] figure 1 with figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 for figure 1 Middle A-A sectional view.

[0017] See figure 1 with figure 2 , a three-dimensional ribbed tube processing cutter bar positioning device with a buffer structure, comprising a base 1, a workpiece carrier 2 arranged on the base, a limited support 3 is arranged on the side of the base, and a An n-shaped tool bar carrier 4 is provided, one end of the n-shaped tool bar carrier is connected to the connection between the base and the limit support through a pin shaft 5, and a locking convex plate 6 is arranged on the base , the locking convex plate and the limiting support are symmetrically arranged on both sides of the base, and a positioning snap ring 7 is arranged on the other end of the n-shaped tool bar carrier, and a positioning snap ring 7 is arranged on the locking convex plate. The card...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com