Vibration-reduction fastener system

A technology of vibration-damping fasteners and bosses, which is applied in the field of rail transit, can solve problems such as adverse effects on system safety and stability, increased cost, and inability to withstand repeated disassembly and tightening, so as to provide safety and stability, reduce The effect of construction cost, convenient installation and fixed operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

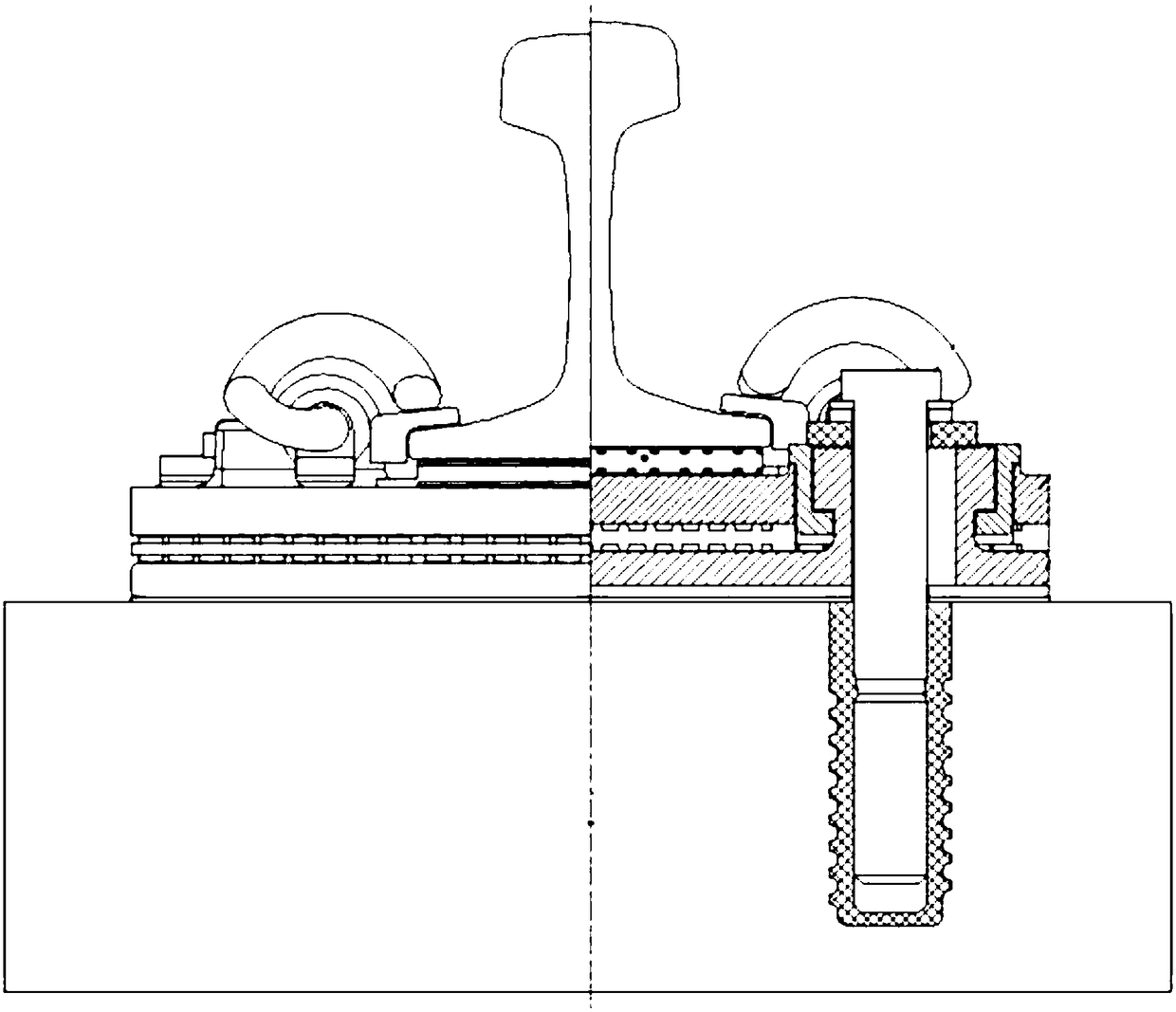

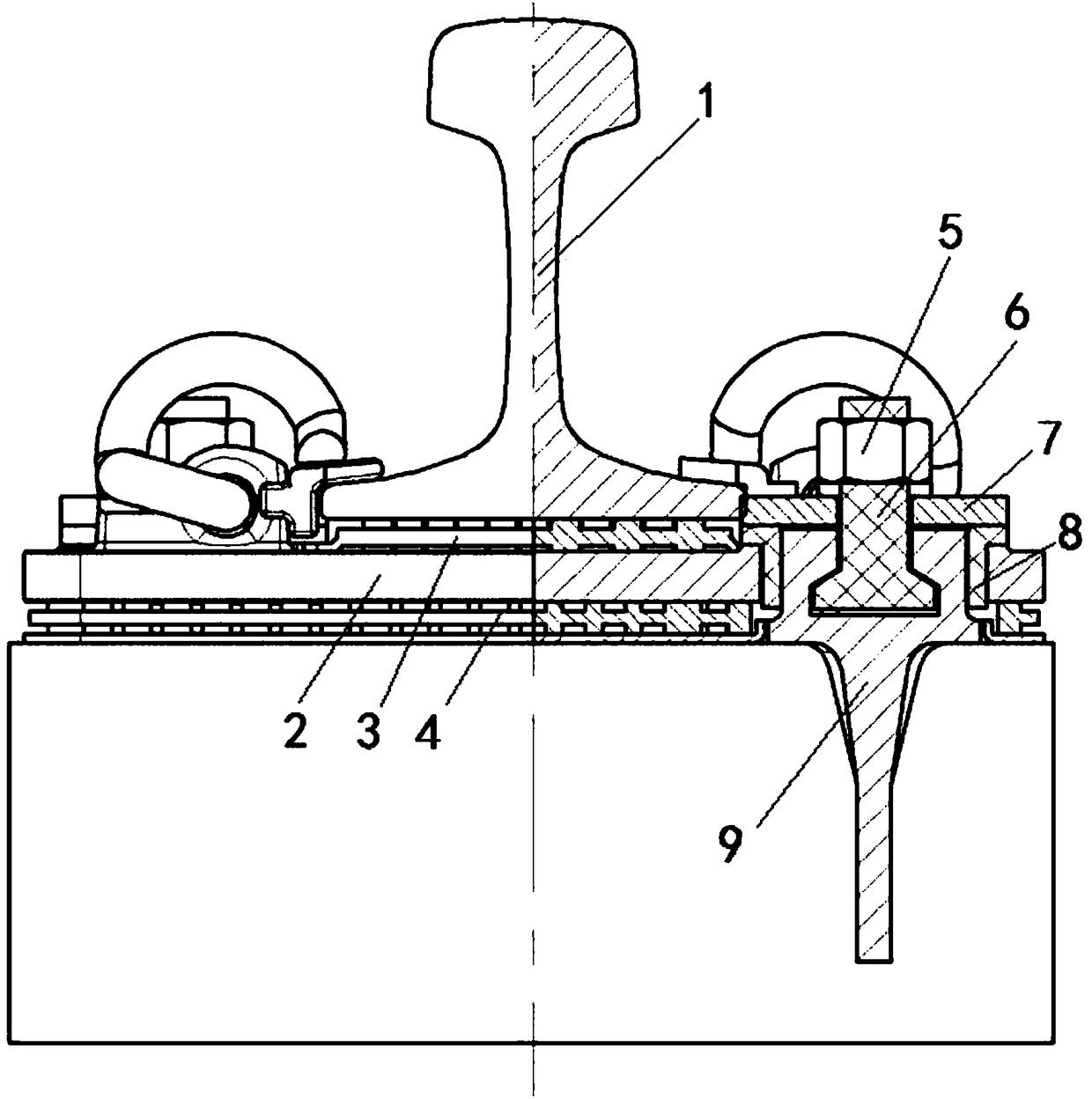

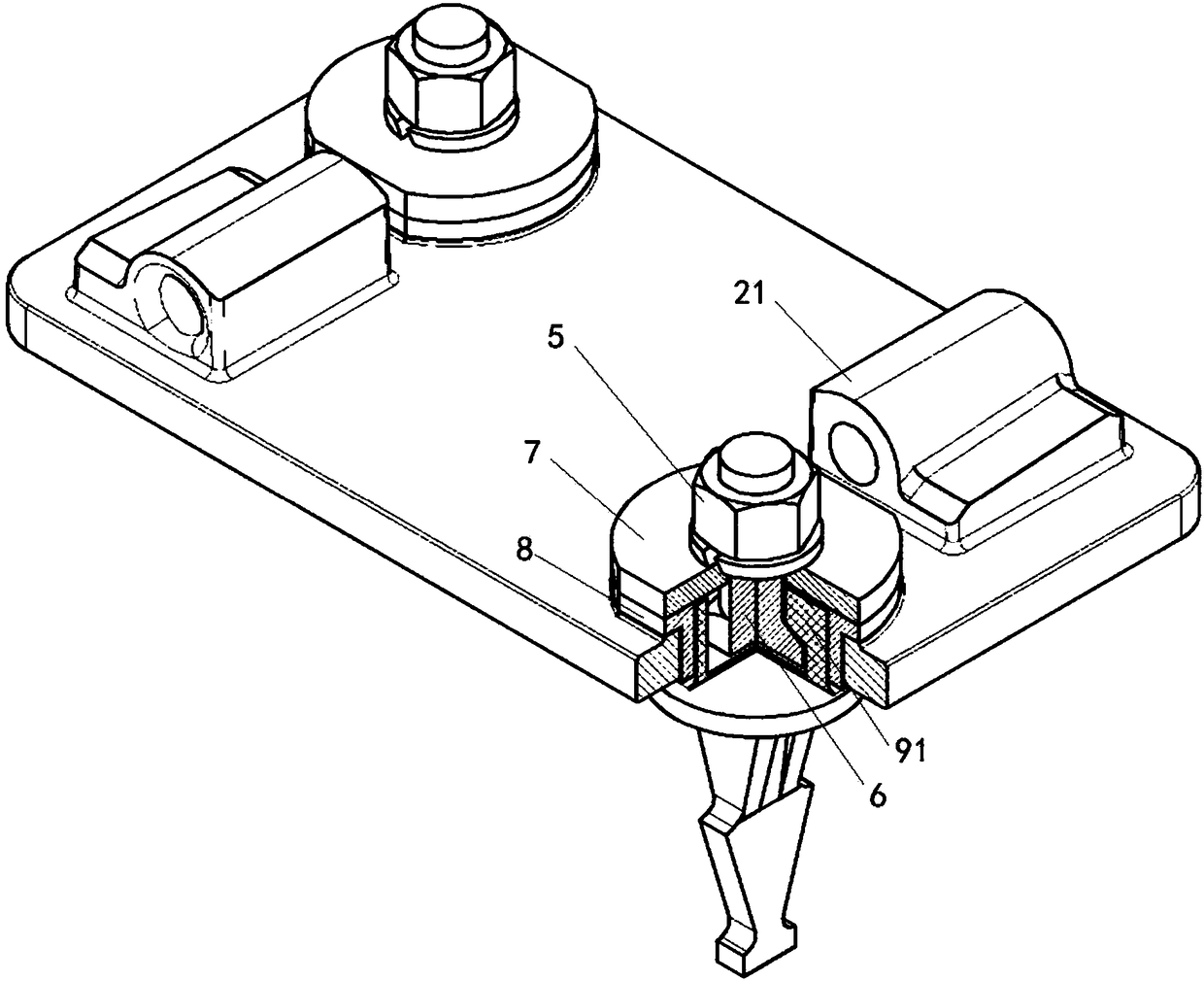

[0066] combine Figure 2-Figure 12 shown;

[0067] The embodiment of the present invention provides a vibration-damping fastener system, including a positioning seat 9, a rail support plate 2, and a locking structure; wherein, the lower part of the positioning seat 9 is a column 92 for embedding the track foundation, and the upper part is a It is used to connect the boss 91 of the rail backing plate 2; the rail backing plate 2 is provided with an elastic seat 21 and a first through hole 22 for the boss 91 to pass through; the locking structure is used to realize the rail backing plate 2 and the locking limit connection between the positioning seat 9.

[0068] In the specific operation, the above-mentioned positioning seat 9 can be pre-embedded in the track foundation, and the connection and support of the rail backing plate 2 can be realized; The connection between them can realize the application of a single-layer metal plate; during the installation process, the rail 1 can...

Embodiment 2

[0091] The substantial difference between the second embodiment and the first embodiment lies in that the connection relationship between the bolt and the protrusion is different.

[0092] The main structure of the vibration-damping fastener system provided in this embodiment is similar to that of Embodiment 1. For the connection of the main structure, please refer to the description of Embodiment 1. This embodiment aims to illustrate the differences between the two.

[0093] In this embodiment, the bottom end of the above-mentioned bolt is integrally connected with the boss; that is, the above-mentioned screw and the positioning seat are integrally formed, and the structural form of the above-mentioned integrally formed structure can avoid the setting of structures such as T-shaped slots. It can also realize the stable connection of the backing plate of the rail; in addition, the top of the bolt is provided with a nut, and the above-mentioned nut can also be provided with a sp...

Embodiment 3

[0095] The substantial difference between the third embodiment and the first embodiment lies in that the connection relationship between the bolt and the protrusion is different.

[0096] The main structure of the vibration-damping fastener system provided in this embodiment is similar to that of Embodiment 1. For the connection of the main structure, please refer to the description of Embodiment 1. This embodiment aims to illustrate the differences between the two.

[0097] In this embodiment, the bottom end of the above-mentioned bolt is threadedly connected with the boss; stable connection; the realization of the above-mentioned threaded connection structure can meet the installation of rail backing plates of different thicknesses, and can effectively improve the adaptability of the fastener system; in addition, the top of the bolt is provided with a head structure, which is used for pressing Lock the cover tightly.

[0098] Further, such as Figure 13 and Figure 14 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com