A metastable cerium oxide or cerium-zirconium solid solution nanomaterial

A technology of cerium-zirconium solid solution and nanomaterials, applied in the direction of catalyst supports, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of inability to form oxide crystals, etc., and achieve the promotion of oxygen Activation, improvement of supply capacity, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 116.3 g of cerium acetylacetonate (12% Ce content) and 82 ml of xylene were mixed to prepare a precursor solution, and the concentration of the cerium precursor was 0.5 mol / L. The solution was placed on a magnetic stirrer and stirred until a clear solution was obtained. Use a syringe to pump the prepared solution into the flame at a rate of 5ml / min. The flame combustion gas is a mixture of methane (0.6L / min) and oxygen (1.9L / min), and the mixture is ejected from a nozzle with a diameter of 2mm. The gas distribution plate is used to blow a large amount of air (6L / min) into the flame area, driven by the high-speed air flow, the combustion products leave the flame area quickly, and the sum of the radial cross-sectional area of the gas through holes on the gas distribution plate is 3.5 square meters cm, the temperature drops to 40°C when the sample reaches the glass fiber filter paper. Catalyst particles obtained by combustion were collected with glass fiber filter pape...

Embodiment 2

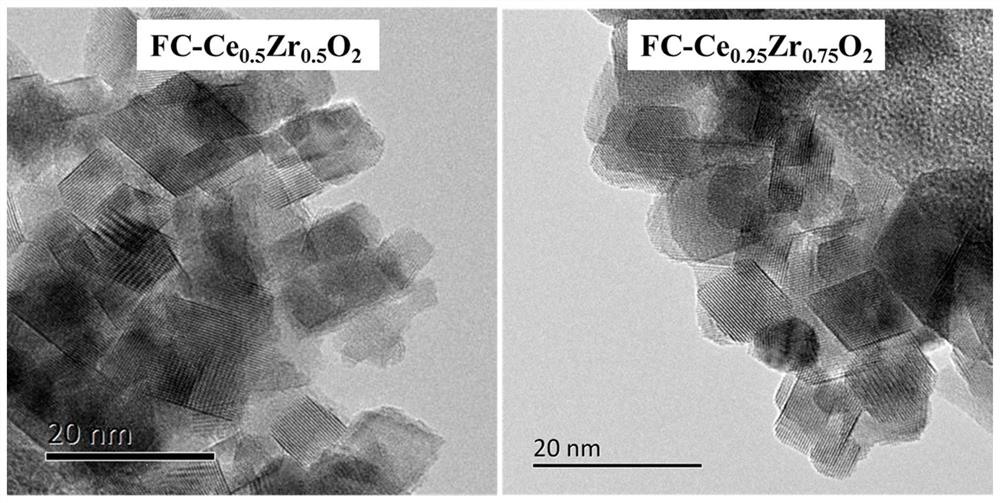

[0021] 65.4 g of cerium acetylacetonate (12% Ce content), 9.8 ml of zirconium acetylacetonate and 74 ml of xylene were mixed to prepare a precursor solution. The solution was placed on a magnetic stirrer and stirred until a clear solution was obtained. Use a syringe to pump the prepared solution into the flame at a rate of 5ml / min. The flame combustion gas is a mixture of methane (0.6L / min) and oxygen (1.9L / min), and the mixture is ejected from a nozzle with a diameter of 2mm. The gas distribution plate is used to blow a large amount of air (6L / min) into the flame area, driven by the high-speed air flow, the combustion products leave the flame area quickly, and the sum of the radial cross-sectional area of the gas through holes on the gas distribution plate is 3.5 square meters cm, the temperature drops to 40°C when the sample reaches the glass fiber filter paper. Catalyst particles obtained by combustion were collected with glass fiber filter paper. The particle diameter...

Embodiment 3

[0023] 43.6g of cerium acetylacetonate (Ce content 12%), 19.6ml of zirconium acetylacetonate and 86ml of xylene were mixed to prepare a precursor solution. The solution was placed on a magnetic stirrer and stirred until a clear solution was obtained. Use a syringe to pump the prepared solution into the flame at a rate of 5ml / min. The flame combustion gas is a mixture of methane (0.6L / min) and oxygen (1.9L / min), and the mixture is ejected from a nozzle with a diameter of 2mm. The gas distribution plate is used to blow a large amount of air (6L / min) into the flame area, driven by the high-speed air flow, the combustion products leave the flame area quickly, and the sum of the radial cross-sectional area of the gas through holes on the gas distribution plate is 3.5 square meters cm, the temperature drops to 40°C when the sample reaches the glass fiber filter paper. Catalyst particles obtained by combustion were collected with glass fiber filter paper. The particle diameter i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com