Hydraulic balanced motor dynamic sealing device

A sealing device and motor-driven technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of increasing maintenance costs, leaking motors, wasting time, etc., achieving simple structure, reducing maintenance costs, and simplifying process links. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings and examples.

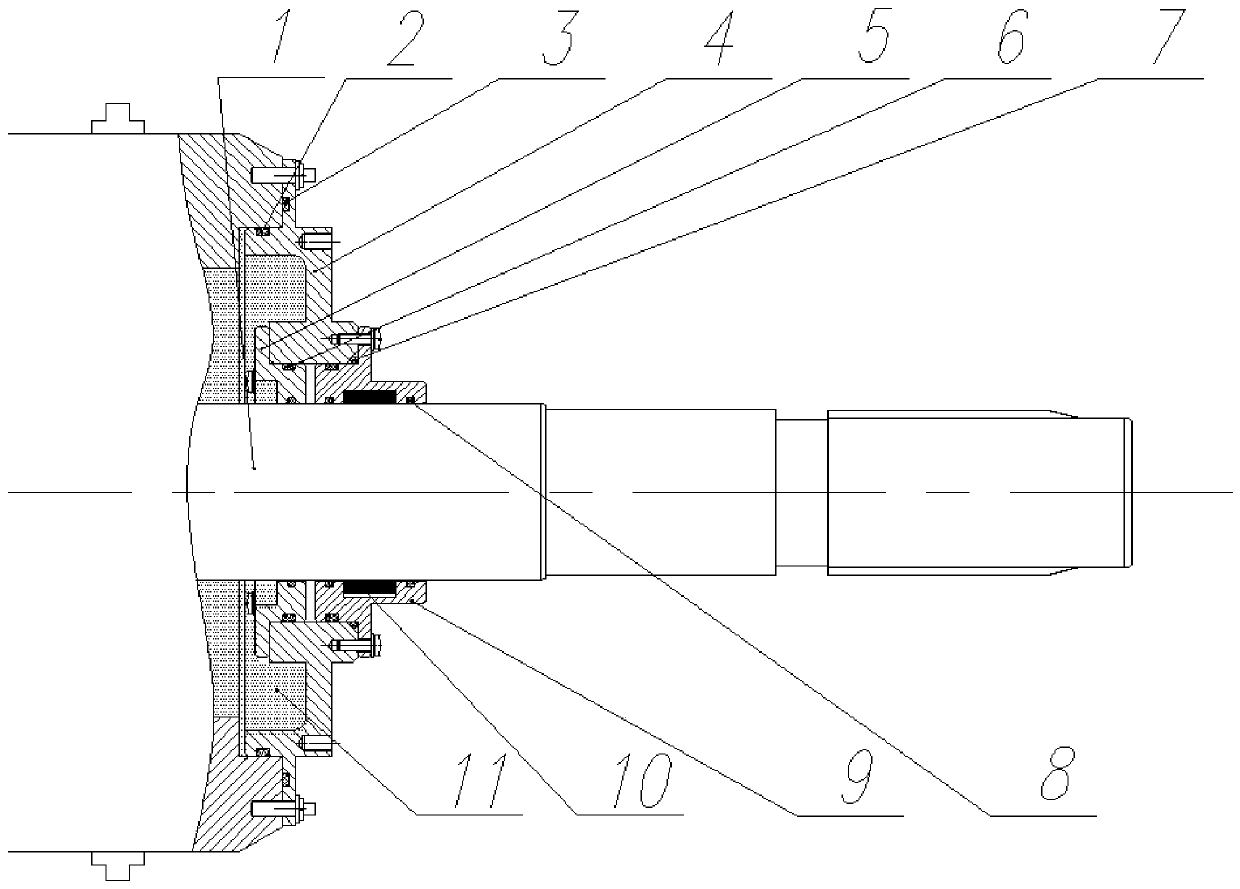

[0015] as attached figure 1 As shown, the present invention provides a dynamic sealing device for an oil pressure balance motor, the device includes an oil pressure balance motor shaft end 1, an O-ring 2, an O-ring 3, a sealing end cover 4, an inner sealing seat 5, a tapered surface O-ring 6, O-ring 7, O-ring 8, outer sealing seat 9, grease 10 and insulating hydraulic oil 11.

[0016] The sealing end cover 4 is fixedly connected to the oil pressure balance motor 1, and the sealing end cover 4 is set on the O-ring by setting an axial O-ring 3 and a radial 45° split mold outer shaft O-ring 2. It needs to be lubricated with 7013 grease, the sealing end cover is made of stainless steel, and the O-ring is made of NBR;

[0017] The inner sealing seat 5 is fixedly connected to the sealing end cover 4, and there are two sealing grooves on the inner sealing seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com