Cylindrical lithium ion battery having internal heat dissipation and tab fixing structure, and preparation method thereof

A lithium-ion battery and fixed structure technology, which is applied in the direction of secondary batteries, structural parts, battery pack parts, etc., can solve problems such as heat conduction and conduction, and achieve the effect of improving current resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

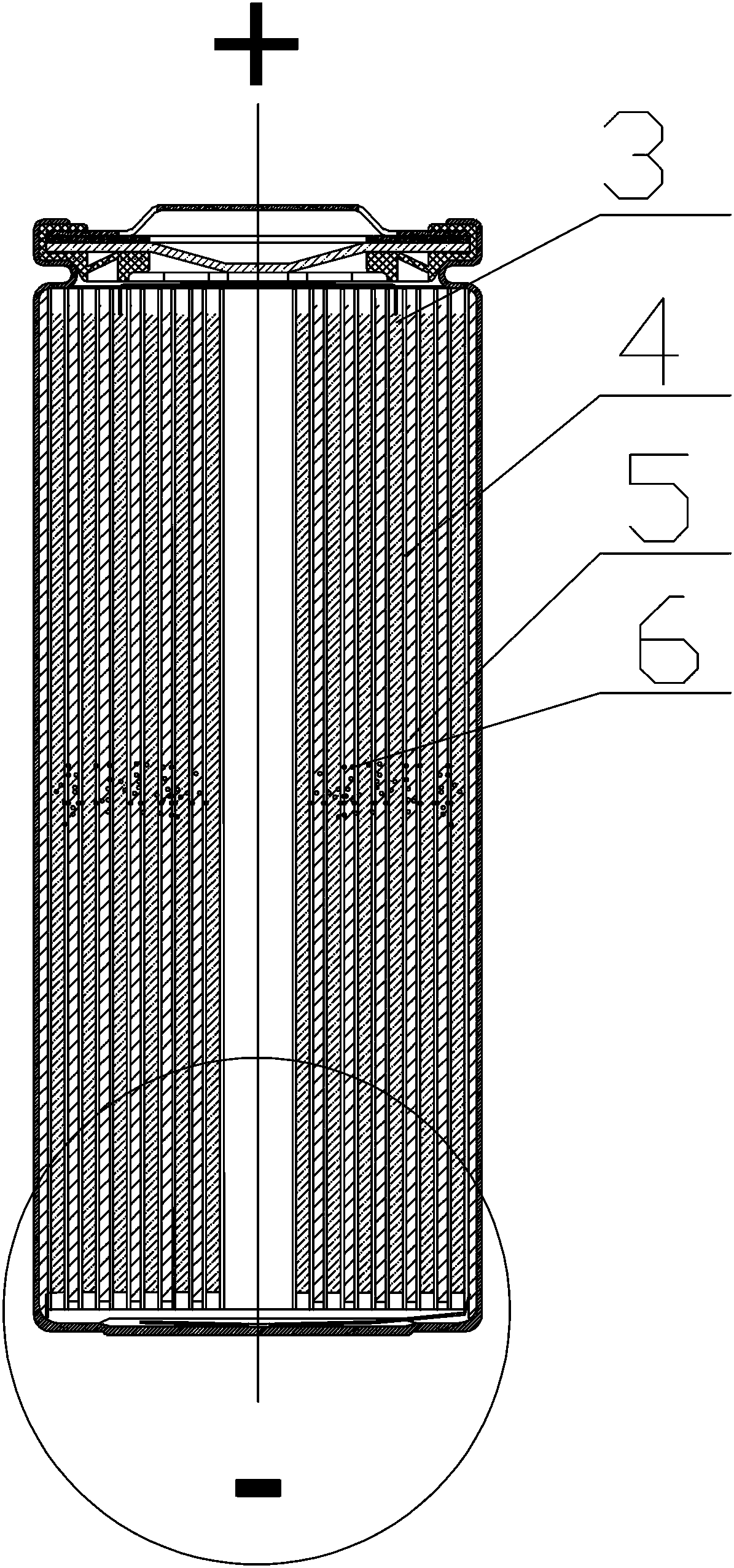

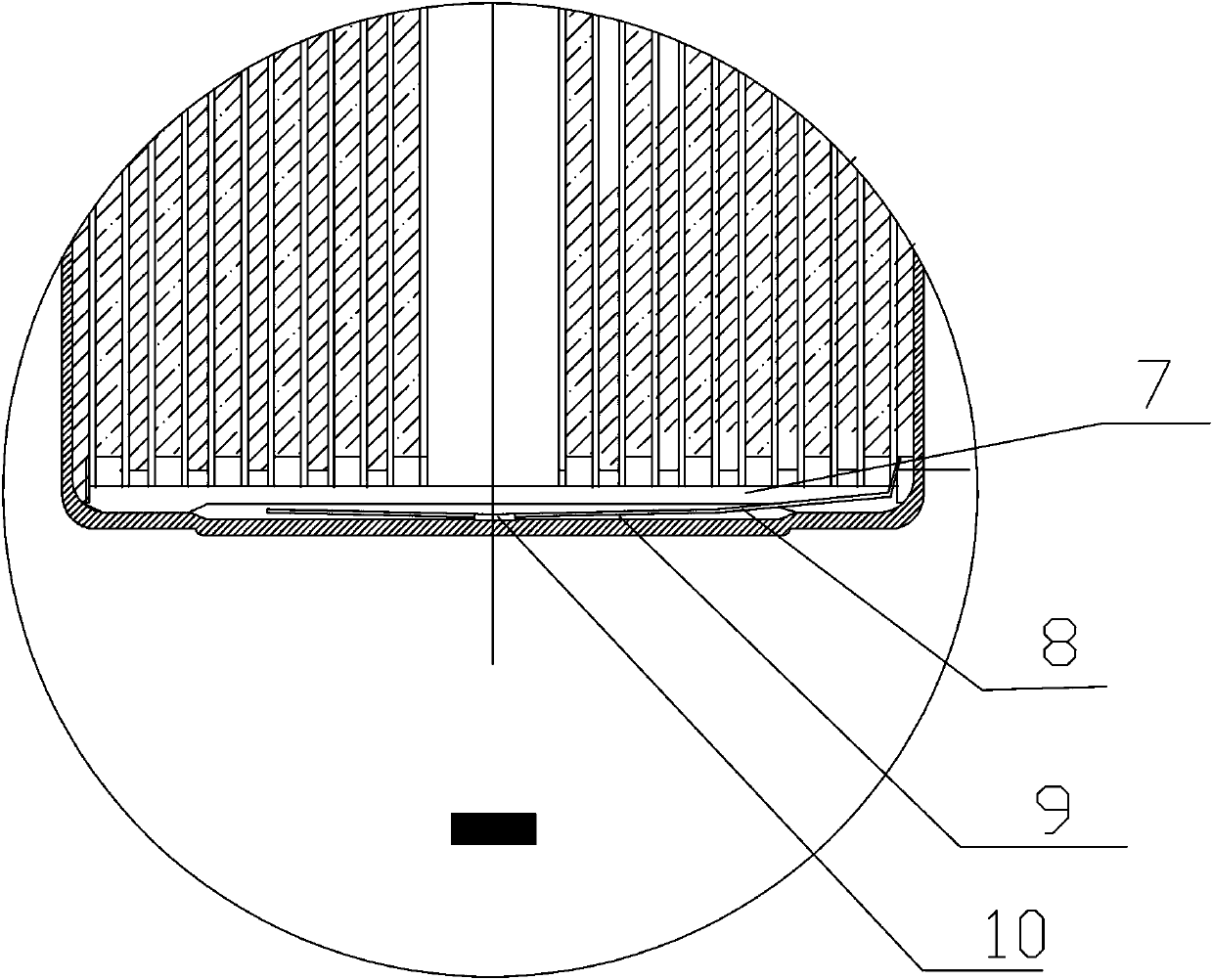

[0020] A cylindrical lithium-ion battery with internal heat dissipation and tab fixing structure and its preparation method, taking the 26650-3Ah-3.2V model battery as an example, the structure is as follows figure 1 , figure 2 The shown includes: a steel shell (1), a cap (2), a positive electrode sheet (3), a separator (4), a negative electrode sheet (5), an electrolyte (6), an insulating layer (7), and a conductive layer (9). A welding point (10) is formed after the battery negative pole tab (8) is spot-bottom welded.

[0021] The tab (8) is wrapped and fixed by the conductive layer (9), and the conductive layer (9) is covered with an insulating layer (7).

[0022] After the inner core of the battery is put into the case, the bottom welding of the negative electrode point is performed to form a welding point (10).

[0023] 5, acetone 70. , triethanolamine 15, copper powder 400, butanediol diglycidyl ether Inject epoxy resin conductive adhesive, and form a conductive la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com