Preparation method of composite electrolyte layer and solid state battery

A technology of composite electrolyte and solid electrolyte, which is applied in the field of preparation of composite electrolyte layer, can solve the problems of non-recyclable, low utilization rate, and stripes on pole pieces, etc., and achieve the effect of improving utilization rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

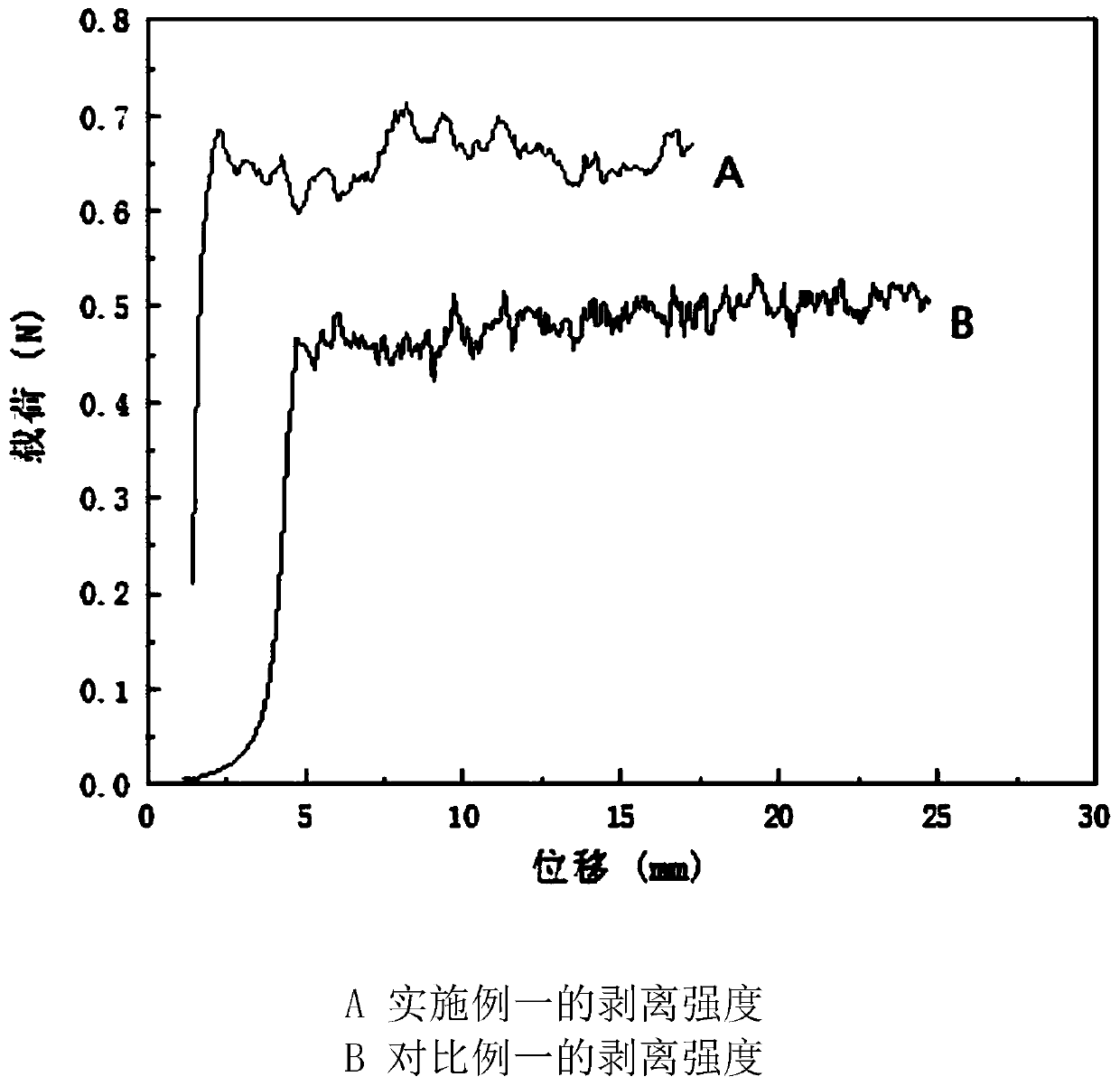

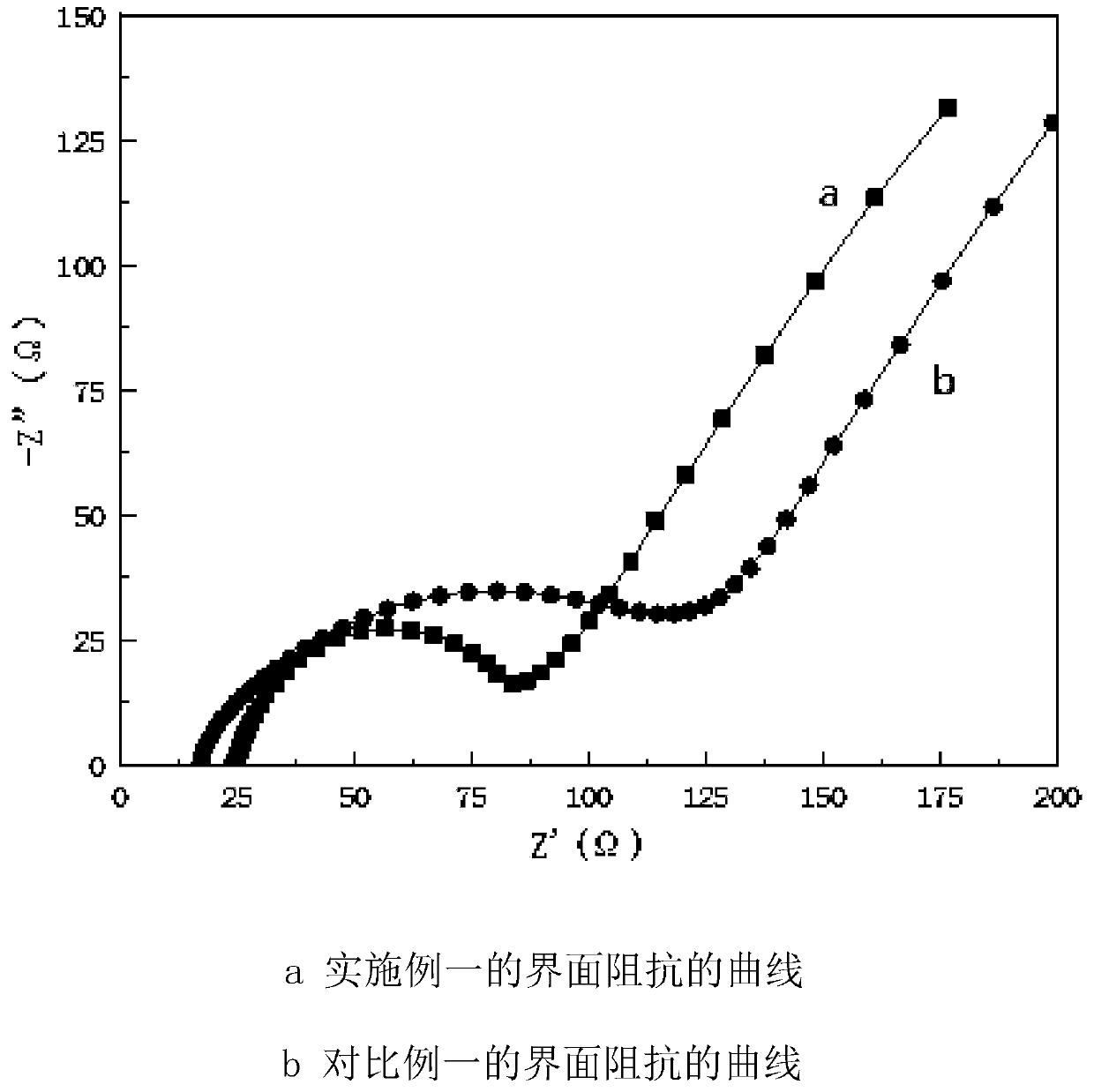

Embodiment 1

[0026] Step 1. Powder mixing

[0027] According to the mass ratio of inorganic solid electrolyte powder: organic polymer powder = 20:1, add it to the VC high-efficiency mixer and mix evenly.

[0028] Step 2. Spraying

[0029] Put the uniformly mixed composite electrolyte powder in step 1 into the electrostatic powder spraying equipment, and spray it on the negative electrode sheet. Spraying process parameters: electrostatic spraying voltage 70KV, distance between spray gun mouth and pole piece 150mm, spraying angle 90°.

[0030] Step three, heat treatment

[0031] The negative electrode sheet in step 2 was subjected to hot isostatic pressing, the temperature of the hot isostatic pressing was 100°C, the hot pressing pressure was 0.3 MPa, and the hot pressing time was 15 minutes, and it was naturally cooled to obtain the following figure 1 structure shown.

[0032] Step 4. Battery Assembly

[0033] The negative electrode sheet with the composite electrolyte layer in step 3 ...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that the inorganic solid electrolyte powder is LiTi 2 (PO 4 ) 3 , The organic polymer powder is polyvinylidene fluoride-hexafluoropropylene copolymer.

Embodiment 3

[0044] Step 1. Powder mixing

[0045] According to the mass ratio of inorganic solid electrolyte powder: organic polymer powder = 15:1, it is added into a VC high-efficiency mixer and mixed evenly to obtain a composite mixture. The inorganic electrolyte powder uses NASICON type Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 , The organic polymer powder is made of polyethylene oxide.

[0046] Step 2. Spraying

[0047] Put the uniformly mixed composite electrolyte powder in step 1 into the electrostatic powder spraying equipment, and spray it on the positive electrode sheet. Spraying process parameters: electrostatic spraying voltage 60KV, distance between spray gun mouth and pole piece 150mm, spraying angle 90°.

[0048] Step three, heat treatment

[0049] Put the positive electrode sheet in step 2 into an oven and keep it warm at 70°C for 20 minutes to melt the composite electrolyte powder, take it out, and put it in a nitrogen environment to cool naturally.

[0050] Step 4. Battery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com