RRAM device based on graphene oxide and preparation method of RRAM device

A graphene and device technology, applied in the field of graphene oxide-based RRAM devices and its preparation, can solve problems such as high production costs, limited equipment, and inability to meet the needs of large-scale and low-cost industrialization, and achieve resistive switching effects Good, less investment in equipment and raw materials, and achieve the effect of large-scale industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

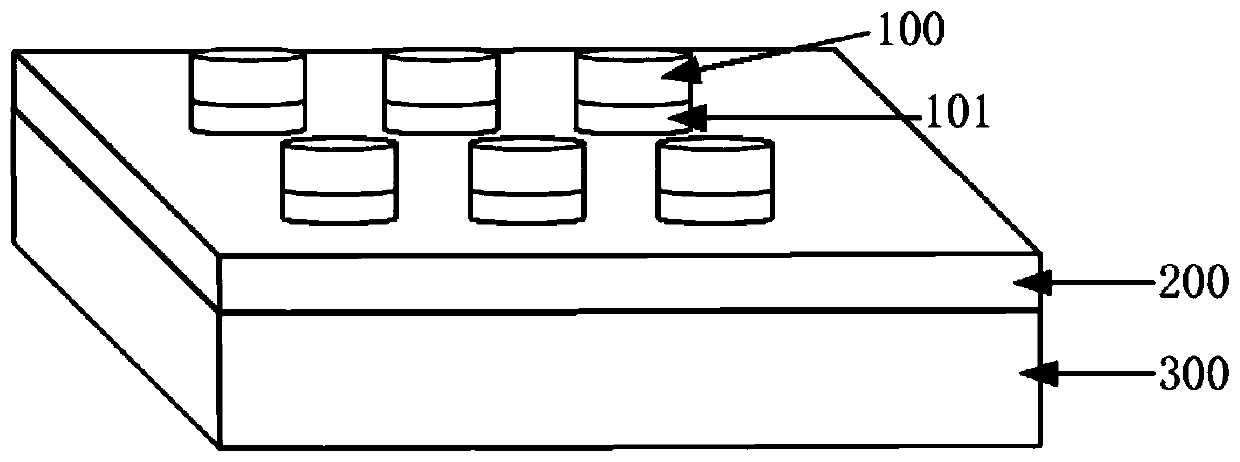

[0033] like figure 1 As shown, this embodiment relates to a graphene oxide-based RRAM device, including a conductive substrate 300, a dielectric layer 200, and a top electrode layer stacked from bottom to top, and the top electrode layer includes several top electrodes arrayed on the dielectric layer 200 101 , the top electrode 101 is provided with a protective layer 100 on the surface away from the dielectric layer 200 .

[0034] The protective layer 100 adopts metal tungsten thin film.

[0035] The top electrode 101 is a cylindrical metal aluminum film with a thickness of 30-80 nm and a diameter of 0.1-0.3 mm, preferably a thickness of 40 nm and a diameter of 0.1 mm.

[0036] The dielectric layer 200 is a graphene oxide film with a thickness of 20-80 nm.

[0037] The conductive substrate 300 adopts a highly doped silicon film with a thickness of 50-150 nm, preferably, an N-type phosphorous-doped highly doped silicon film with a thickness of 100 nm.

[0038] This embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com