A kind of preparation method of discontinuous shielding tape

A non-continuous, shielding tape technology, applied in the direction of power cables with shielding layer/conductive layer, chemical instruments and methods, cables with twisted strands/twisted strands, etc., can solve the problem of single slit width, etc. Problems, achieve the effect of reducing signal strings, increasing diversity, and improving stretching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Attached below Figure 1-7 , and further illustrate the technical solution of the present invention through specific embodiments.

[0056] Unless specifically stated, various raw materials of the present invention can be purchased commercially, or can be prepared according to conventional methods in the art.

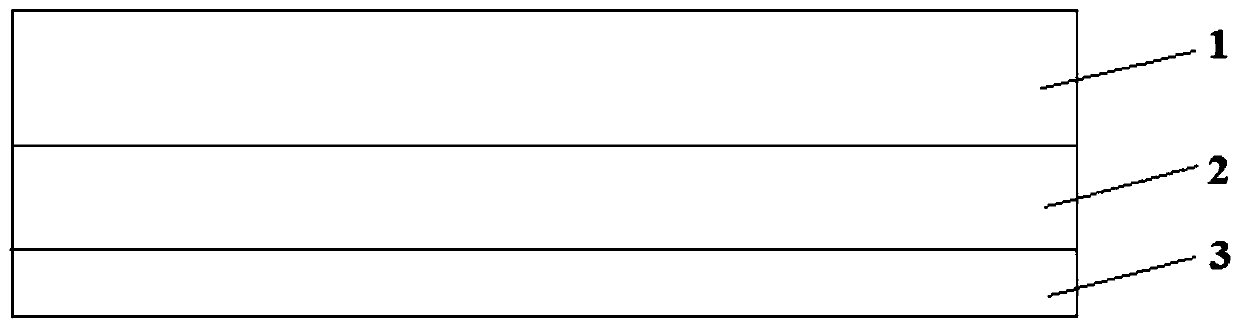

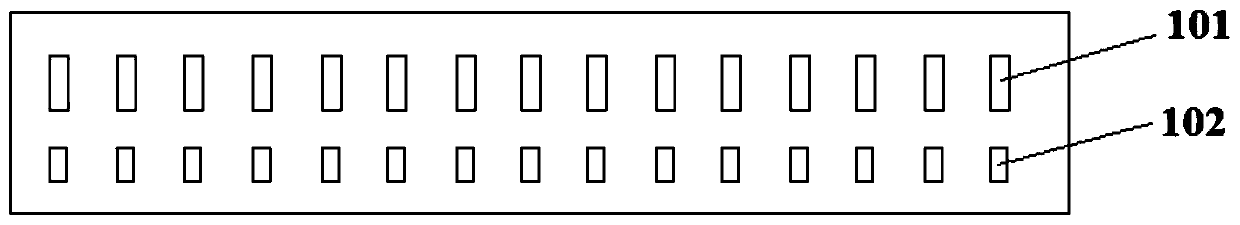

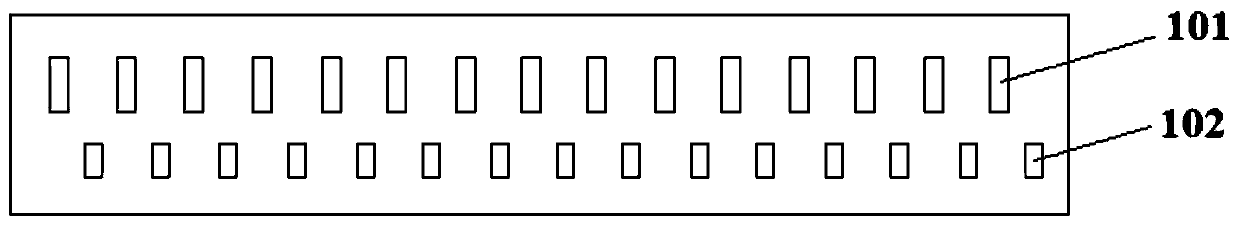

[0057] like figure 1 As shown, the discontinuous shielding tape of the present invention includes a metal layer 1, a first polyester film layer 2 and a second polyester film layer 3 arranged in sequence from top to bottom, and the metal layer 1 is provided with a first slit 101 The slit widths of the first slit 101 and the second slit 102 are different from those of the second slit 102 . Wherein, the relative positions of the first slit 101 and the second slit 102 on the metal layer 1 can be arranged in parallel, such as figure 2 , 3 Shown; The relative positions of the first incision 101 and the second incision 102 can also be staggered, as Figure 4 shown....

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com