Double-tube extrusion type layered water stop

An extrusion-type, water-stop technology, applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problem of limited application scope, reduced development cost, and easy gas leakage of inflatable water-stop devices and other problems, to achieve the effect of good sealing effect, low cost and convenient pumping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

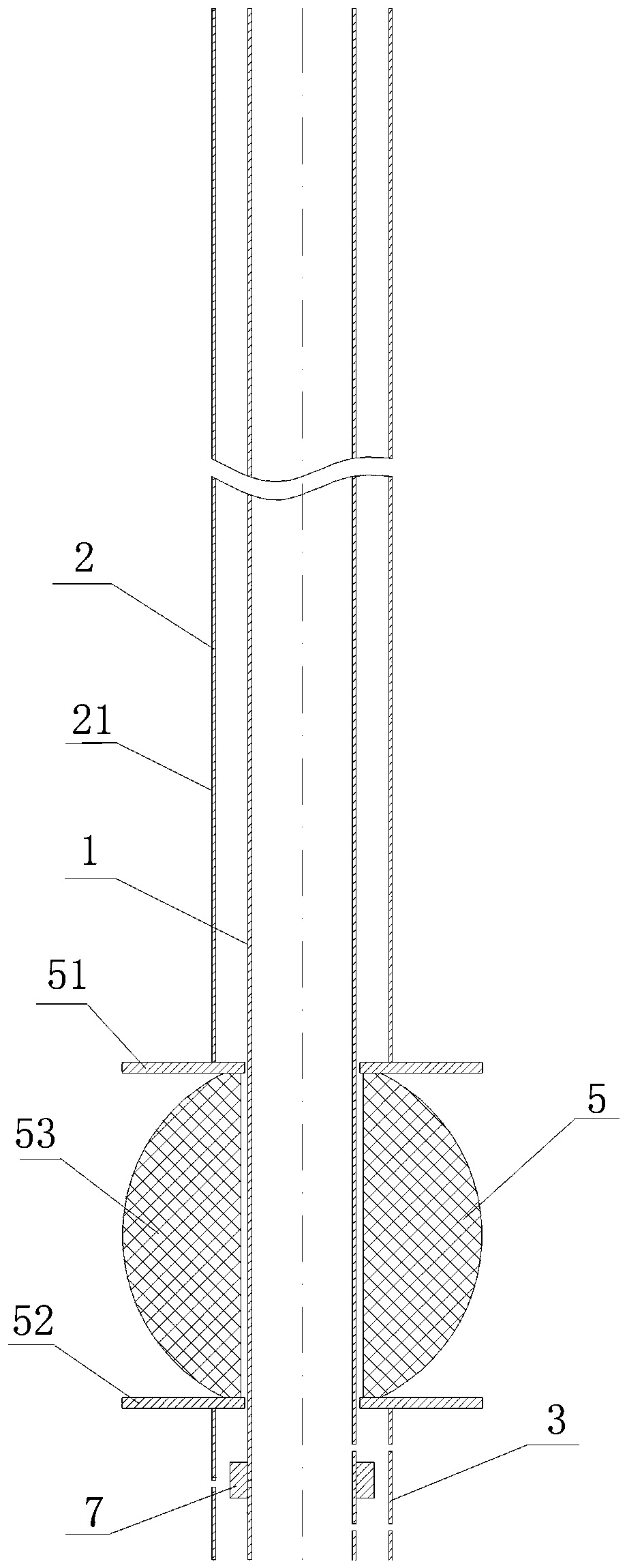

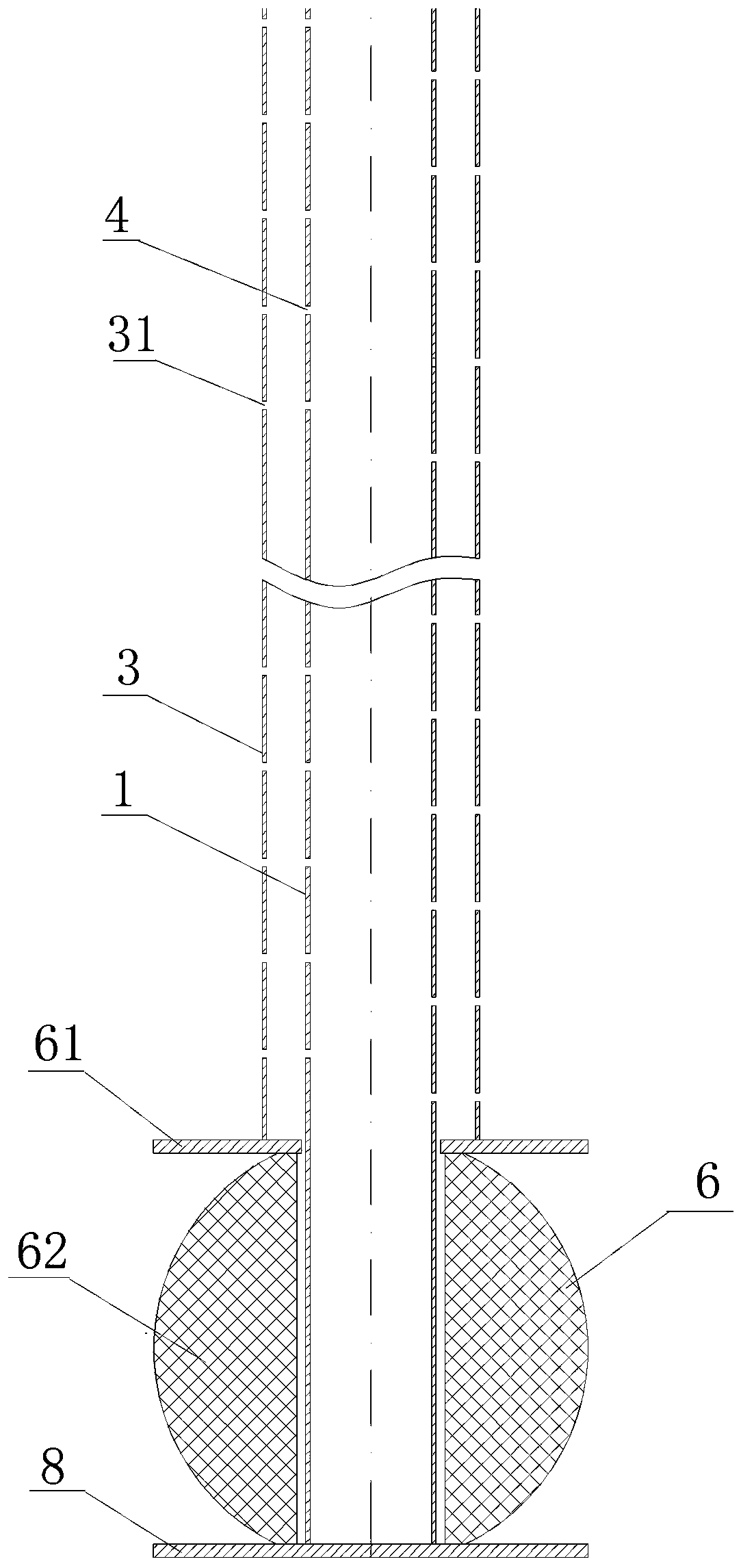

[0033] A double-tube extrusion type layered water stop, combined with Figure 1 to Figure 3 As shown, it includes an inner pipe 1 , an outer pipe 2 , an upper water-stopping mechanism 5 , a lower water-stopping mechanism 6 , a water inlet channel and a bottom baffle 8 .

[0034] The top end of the inner tube 1 is connected with a hoist, and the hoist pulls up the inner tube 1 for positioning. The inner diameter of the inner tube 1 is 28 mm, and the inner tube 1 can be formed by connecting a plurality of segmented tubes of a certain length in sequence, and the segmented tubes are connected by screws. During the actual pumping operation, a water pump is connected to the middle of the inner pipe 1, and the water pump is used to pump the water in the test aquifer into the inner pipe.

[0035] The outer tube 2 is sleeved outside the inner tube 1, the distance between the inner wall of the outer tube 2 and the inner tube is 9mm, and the top end is connected with the hydraulic head,...

Embodiment 2

[0049] On the basis of Example 1, this example is different from Example 1 in that the top deformation blocking structure is set as a white gauze bag containing dry clay a, and the bottom deformation blocking structure is set as a white gauze bag containing dry clay b, dry clay in a knotted white gauze bag a and dry clay in a knotted white gauze bag b, specifically, dry clay in an elastic rubber band knotted white gauze bag. The arrangement of the knotted white gauze bag dry clay a and the knotted white gauze bag dry clay b makes the device more suitable for layered water-stopping of loose aquifers such as sand, pebbles and gravel, thereby increasing the application of the device scope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com