Drainage casing pipe capable of preventing odor and backflow

An anti-backflow and casing technology, which is applied in the direction of drainage structures, water supply devices, waterway systems, etc., can solve the problems of downward leakage, easy water accumulation, leakage, etc., to avoid water accumulation, prevent backflow, and prevent odor the emanating effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

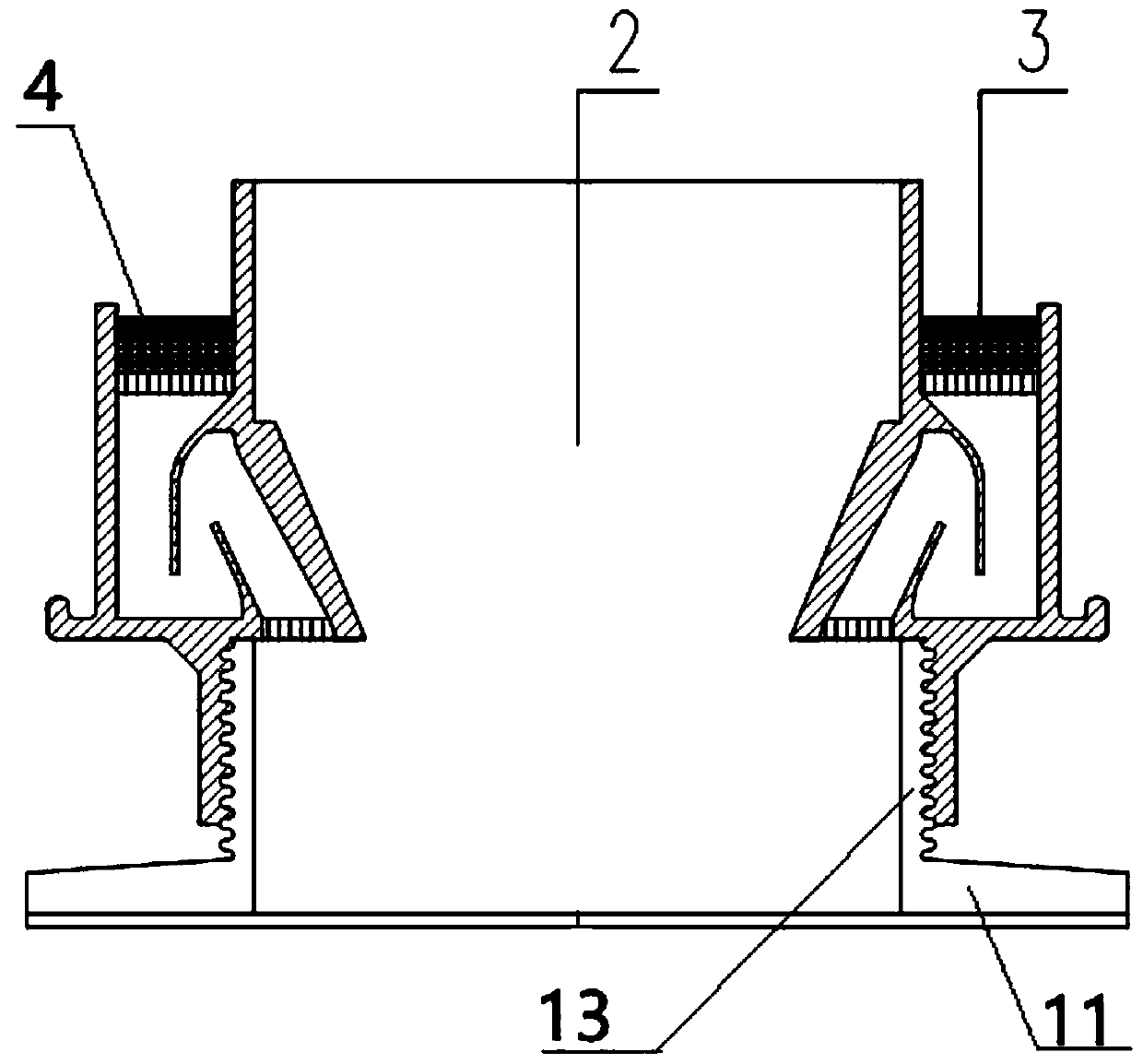

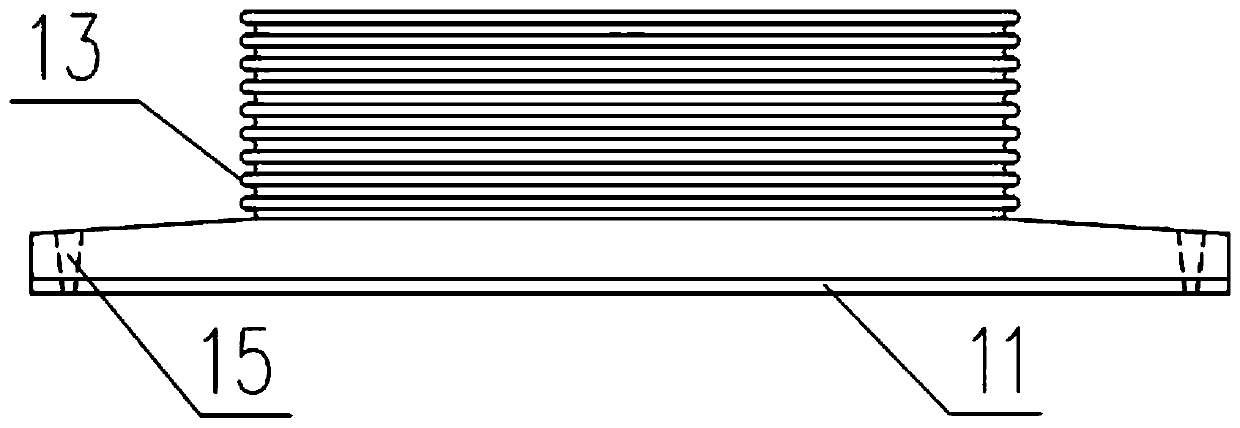

[0036] Such as figure 1 , image 3 and Figure 4 As shown, a drainage casing capable of deodorizing and preventing backflow includes a horizontally arranged chassis 11 and a vertically arranged casing 13, the chassis 11 is provided with a through hole, and the bottom end of the casing 13 is connected to the bottom of the casing 13. The top surface of the chassis 11 is fixedly connected, and the through hole communicates with the inner cavity of the sleeve 13, and the top of the sleeve 13 is provided with a drainage and water-stop joint device 2 capable of deodorizing and preventing backflow. The water section device 2 is sheathed with an annular drainage screen device 3 capable of filtering impurities.

[0037] Specifically, the diameter of the sleeve 13 is smaller than the diameter of the chassis 11 , and the chassis 11 is provided with a mounting hole 15 , and the mounting hole 15 is provided with a screw for fixing the chassis 11 .

[0038] Specifically, the drainage wat...

Embodiment 2

[0044] Such as Figure 5 and Figure 6 As shown, the difference from Embodiment 1 is that the annular drainage screen device 3 includes an outer ring 31, an inner ring 32 and eight third connecting posts 33, and the diameter of the inner ring 32 is smaller than that of the outer ring 31. diameter, the inner side of the inner ring 32 abuts against the outer side of the top collar 21, the outer side of the inner ring 32 is connected to the inner side of the outer ring 31 through eight third connecting posts 33, and the outer ring 31 abuts against the inner side of the outer wall sleeve 24 , and the gap formed by the inner ring 32 , outer ring 31 and eight third connecting columns 33 is filled with a filter screen 34 . The eight third connecting columns 33 are arranged at equal intervals.

[0045] Specifically, a sponge pad 4 is provided on the bottom surface of the filter screen 34 , and the sponge pad 4 is fixedly connected with the top sleeve 21 and the outer wall sleeve 24 ...

Embodiment 3

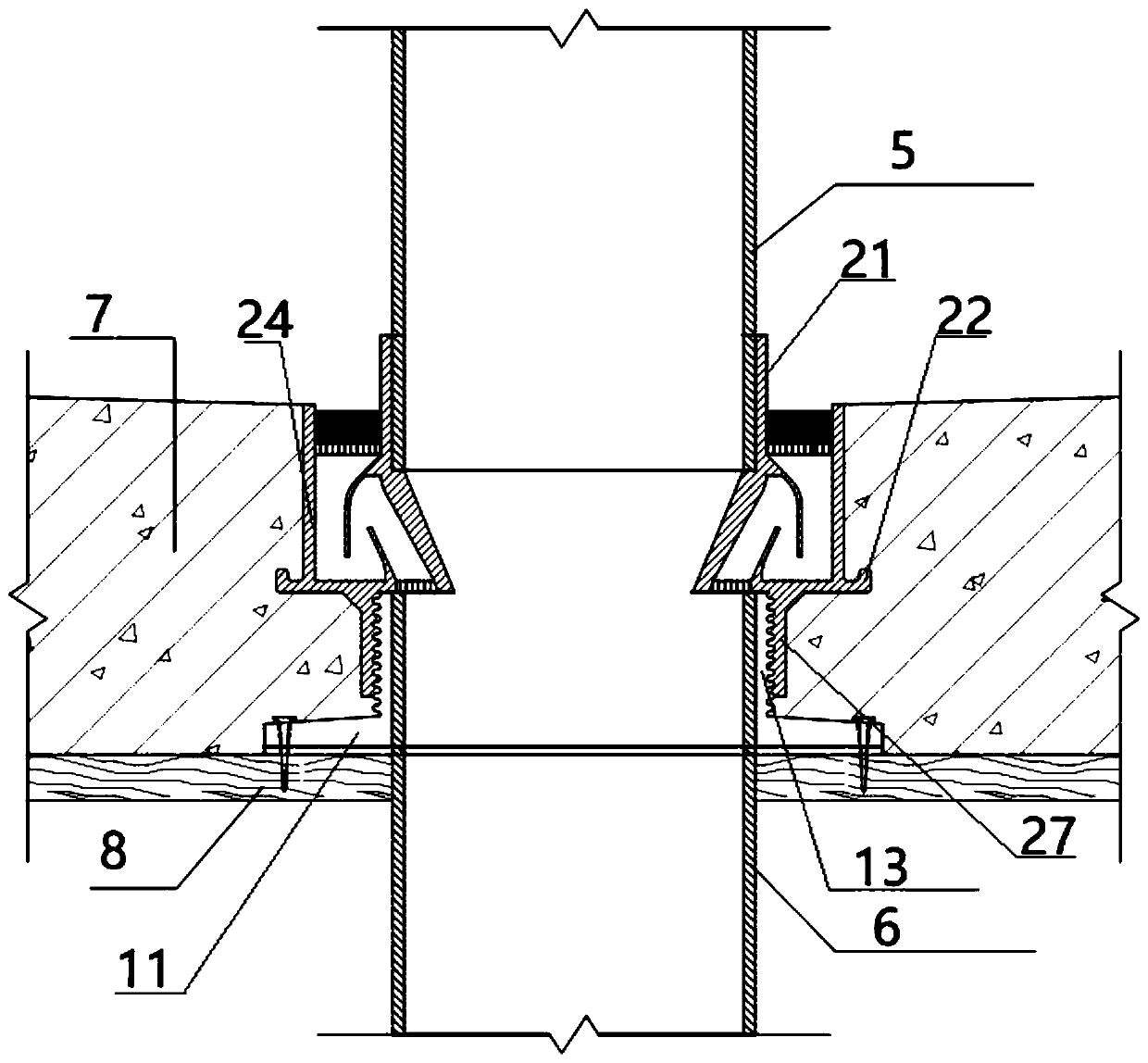

[0048] Such as figure 2 As shown, the difference from Example 1 is that the present invention is generally pre-embedded in the structural slab 7 during the structural construction process. When in use, the screws pass through the mounting holes 15 to fix the chassis 11 on the formwork 8, and after being fixed in place, the Brush the pipe special glue on the casing 13 on the chassis 11, screw the bottom casing 27 with the casing 13 and screw it into the casing 13, adjust the height of the outer wall casing 24 according to the thickness of the structural layer 7 during the screwing process It is the same height as the top surface of the structure layer 7 and the mechanism layer 7. Then, before concrete pouring, protective measures can be taken for the present invention. The protective measures refer to a preventive measure taken during the concrete pouring process to prevent slurry or aggregate from flowing into the present invention. Further protective measures can be adopted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com