Garbage salvage device with transverse interception function for hydraulic engineering

A water conservancy project and salvage device technology, which is applied in water conservancy projects, cleaning of open water surfaces, construction, etc., can solve the problems of unable to intercept the garbage of the interception net, cannot remove the interception net garbage, etc., and achieve the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

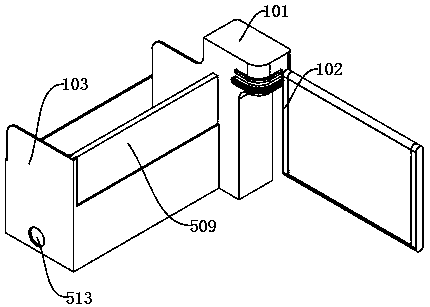

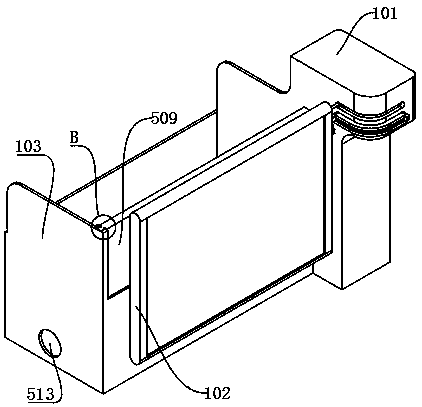

[0031]A garbage salvage device for water conservancy projects with a horizontal interception function, comprising: a support shell 101, a buoyancy shell 102, and a recycling garbage bin 103, and also includes: a double-motor transmission mechanism, a rotating net cleaning mechanism, a lifting recovery mechanism, and a limit rotation mechanism , the inside of the support shell 101 is fixedly equipped with a dual-motor transmission mechanism, the front end of the dual-motor transmission mechanism is meshed with the rotating net cleaning mechanism, and the left side of the front end of the support shell 101 is fixedly installed with a limit rotation mechanism, and the limit rotation mechanism is fixedly connected with the rotation net cleaning mechanism , the inside of the buoyancy shell 102 is fixedly equipped with a rotating net cleaning mechanism, the left side of the double motor transmission mechanism is fixedly connected with the lifting recovery mechanism, and the lifting re...

Embodiment 2

[0034] Embodiment 2: the difference based on Embodiment 1 is;

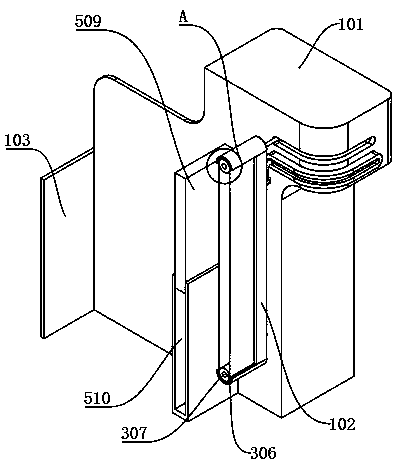

[0035] The rotating net cleaning mechanism comprises: upper rotating rod 301, rotating fixed block 302, docking gear 303, rotating shaft 304, upper rotating wheel 305, lower rotating wheel 306 and transmission shaft 307, upper rotating gear 207 upper surface middle part and upper rotating rod 301 The lower end on the right side is fixedly connected, the lower end on the left side of the upper rotating rod 301 is fixedly connected to the middle part of the upper surface of the rotating fixed block 302, and the upper and lower sides on the left side of the upper rotating gear 207 and the lower rotating gear 208 are meshed with the upper and lower sides of the docking gear 303. The shaft center of the gear 303 is fixedly connected with the right end of the rotating shaft 304, the rotating shaft 304 is movably sleeved inside the shaft center of the rotating fixed block 302, the left side of the rotating shaft 304 is fi...

Embodiment 3

[0039] Embodiment 3: the difference based on embodiment 1 and 2 is;

[0040] The lifting recovery mechanism includes: ratchet drive belt group 501, fixed shaft 502, rotating helical gear 503, transmission helical gear 504, screw mandrel 505, support block 506, lifting moving block 507, lifting connecting rod 508, moving door 509 and moving groove 510, The front end of the main shaft of the upper motor 201 is fixedly connected to the right axis of the ratchet transmission belt group 501, the left axis of the ratchet transmission belt group 501 is fixedly connected to the middle of the fixed shaft 502, the front end of the fixed shaft 502 is movably connected to the inner wall of the support shell 101, and the rear end of the fixed shaft 502 It is fixedly connected with the axis of the rotating helical gear 503, and the lower side of the rotating helical gear 503 is meshed with the transmission helical gear 504. The axis of the transmission helical gear 504 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com