Road construction method

A road construction and subgrade technology, applied in roads, roads, buildings, etc., can solve problems such as tensile performance impact, safety impact, road surface cracking, etc., and achieve the effects of enhancing temperature resistance, improving safety, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

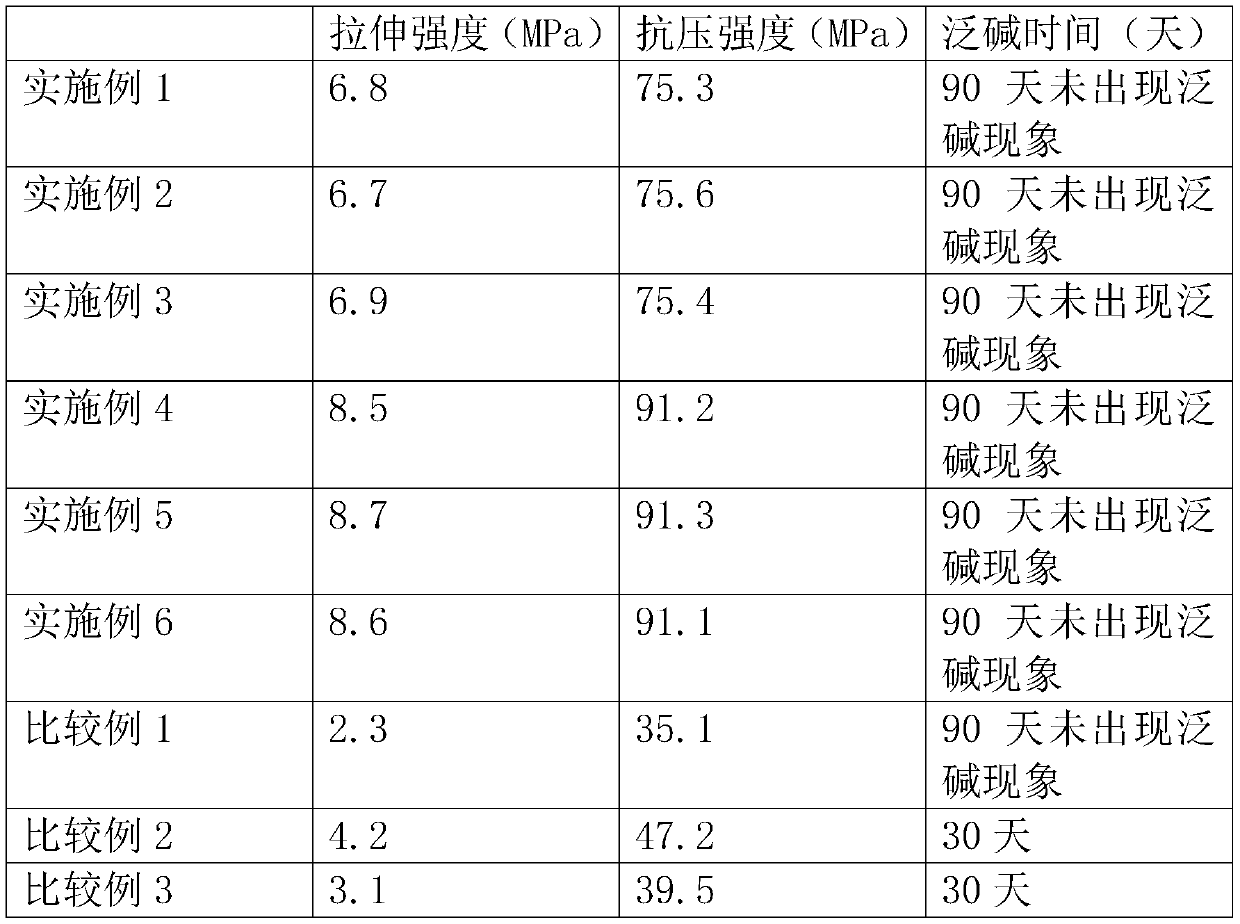

Examples

Embodiment 1

[0060] A road construction method comprising the steps of:

[0061] S1. Excavate roadbed trenches, details are as follows:

[0062] Excavate the road surface according to the design drawings to form roadbed grooves.

[0063] S2. Cleaning and leveling the subgrade groove, details are as follows:

[0064] Level the roadbed groove, compact it with a road roller, and then clean the dust in the roadbed groove.

[0065] S3. Road base laying, details are as follows:

[0066] Pave the lime-soil cushion in the subgrade groove, and the volume ratio of lime-soil to the lime-soil cushion is 3:7. Control the laying thickness of the lime-soil cushion to 30cm. After the paving is completed, it will be manually leveled and compacted with a 20T road roller to form the road base.

[0067] S4. Laying of rubber asphalt, details are as follows:

[0068] Spread rubber asphalt evenly on the lime-soil cushion, and control the paving thickness of rubber asphalt to 30cm.

[0069] In this embodime...

Embodiment 2

[0078] The difference with embodiment 1 is:

[0079] Concrete includes the following components in parts by mass:

[0080] Portland cement 17kg; fine sand 40kg; mineral powder 17kg; gravel 70kg; water 20kg; 9-anthracene carboxylic acid 2.5kg; phenol 1kg; dilute hydrochloric acid 3kg.

[0081] The preparation method of concrete is as follows: add 17kg of Portland cement, 40kg of fine sand, 17kg of mineral powder, 70kg of gravel, and 20kg of water into a 200L stirring tank, stir at a speed of 150r / min, and add 9-anthracene while stirring 2.5kg of formic acid, 1kg of phenol, and 3kg of dilute hydrochloric acid are mixed evenly to form concrete.

Embodiment 3

[0083] The difference with embodiment 1 is:

[0084] Concrete includes the following components in parts by mass:

[0085] Portland cement 20kg; fine sand 35kg; mineral powder 20kg; gravel 73kg; water 10kg; 9-anthracene carboxylic acid 3kg; phenol 1.5kg;

[0086] The preparation method of concrete is as follows: add 20kg of Portland cement, 35kg of fine sand, 20kg of mineral powder, 73kg of gravel, and 10kg of water into a 200L stirring tank, stir at a speed of 150r / min, and add 9-anthracene while stirring 3kg of formic acid, 1.5kg of phenol, and 2kg of dilute hydrochloric acid are mixed evenly to form concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com