Formula and preparation method of nano and nano-micron carbon material-reinforced ultrafine grain surface layer tissue and steel material with surface layer structure

A technology of ultra-fine grain and surface structure, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problem of decreased proportion, insufficient depth of diffusion layer, no nano, nano-micron diamond and nano-carbon Material thermal diffusion, solid dispersants and penetration enhancers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

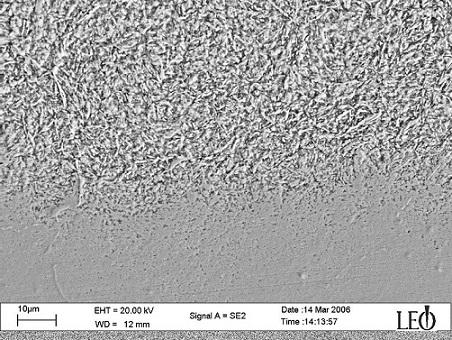

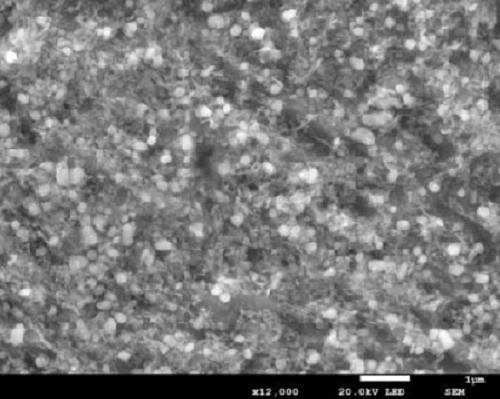

Image

Examples

Embodiment 1

[0095] Embodiment 1: A kind of nanometer, nanometer carbon material strengthens the prescription of superfine grain surface structure, comprises component A, and component A is made of nanometer or nanometer scale diamond, carbon nanotube, graphene and fullerene of at least one component. In one of the embodiments, component A is composed of diamond and carbon nanotubes, and the mass ratio of diamond is 20-50%, and the mass ratio of carbon nanotubes is 50-80%; in one of the embodiments, the component A is made up of diamond and graphene, diamond accounts for 20-50% by mass, and graphene accounts for 50-80% by mass; in one embodiment, diamond accounts for 80-99% by mass, carbon nanotubes, Graphene and fullerene together account for 1%-20%;

Embodiment 2

[0096] Embodiment 2: A kind of nanometer, nanometer carbon material strengthens the prescription of superfine grain surface structure, comprises component A and component B, and component A is made of nanometer or nanometer scale diamond, carbon nanotube, graphene and Composed of at least one component in fullerene, component B is composed of SiC, Si-Fe, B4C, B-Fe, Al2O3, Cr, Cr-Fe, VC, V-Fe, Ti-Fe in nanometer or nanometer scale , TiC, WC, ZrO2, CBN and RE at least one composition, the weight ratio of component A is 90~100%, and the weight ratio of component B is 0~10%. In one of the embodiments, the formula includes diamond of component A and SiC of component B, the weight ratio of diamond is 90-95%, and the weight ratio of SiC is 5-10%.

Embodiment 3

[0097] Embodiment 3: A kind of nanometer, nanometer carbon material strengthens the prescription of superfine grain surface structure, comprises component A, component B and component C, and component A is made of nanometer or nanometer scale diamond, carbon nanotube , graphene and fullerene, component B is composed of SiC, Si-Fe, B4C, B-Fe, Al2O3, Cr, Cr-Fe, VC, V-Fe in nanometer or nanometer scale , Ti-Fe, TiC, WC, ZrO2, CBN and RE at least one component composition, component C is composed of at least one component of dispersant, active agent. The weight ratio of component A is 80-95%, the weight ratio of component B is 2-8%, and the weight ratio of component C is 1-12%.

[0098] (2) A preparation method for nano, nano and micro carbon materials to enhance the superfine grain surface structure

[0099] Embodiment 1: A kind of nanometer, nanometer carbon material strengthens the preparation method of superfine grain surface structure, comprises the following steps:

[0100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com