A kind of non-quenched and tempered steel and its preparation method

A technology for non-quenched and tempered steel and billet, applied in the field of non-quenched and tempered steel and its preparation, can solve the problems of inability to meet the design requirements of water jacket steel, reduce production efficiency, material waste, etc., so as to improve production and processing efficiency and prolong service life , The effect of reducing the weight of the blank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The non-quenched and tempered steel of this embodiment contains the following components by weight percentage: carbon: 0.19%, silicon: 0.55%, manganese: 1.25%, chromium: 0.08%, aluminum: 0.010%, nickel: 0.01%, copper: 0.05% %, phosphorus: 0.012%, sulfur: 0.057%, vanadium: 0.07%, nitrogen: 0.0157%, lead: 0.002%, tin: 0.003%, arsenic: 0.003%, antimony: 0.004%, and the balance is iron.

[0048] The preparation method of the non-quenched and tempered steel of the present embodiment comprises the steps:

[0049] 1. EAF smelting

[0050] According to the above ingredients, the ingredients are sent to the electric furnace for smelting; during the smelting process, the proportion of molten iron entering the furnace is controlled to be ≥50%, and the proportion of scrap steel is ≤50%, so as to meet the requirements of copper, lead, tin, arsenic and antimony in the composition. content requirements; in addition, control electric furnace tapping P≤0.015%, prohibiting slag during t...

Embodiment 2

[0067] The non-quenched and tempered steel of this embodiment contains the following components by weight percentage: carbon: 0.20%, silicon: 0.55%, manganese: 1.26%, chromium: 0.10%, aluminum: 0.013%, nickel: 0.02%, copper: 0.06% %, phosphorus: 0.010%, sulfur: 0.055%, vanadium: 0.09%, nitrogen: 0.0163%, lead: 0.002%, tin: 0.005%, arsenic: 0.003%, antimony: 0.003%, and the balance is iron.

[0068] The preparation method of the non-quenched and tempered steel of the present embodiment comprises the steps:

[0069] 1. EAF smelting

[0070] According to the above ingredients, the ingredients are sent to the electric furnace for smelting; during the smelting process, the proportion of molten iron entering the furnace is controlled to be ≥50%, and the proportion of scrap steel is ≤50%, so as to meet the requirements of copper, lead, tin, arsenic and antimony in the composition. Content requirements; in addition, control electric furnace tapping P≤0.015%, prohibiting slag during t...

Embodiment 3

[0087] The non-quenched and tempered steel of this embodiment contains the following components by weight percentage: carbon: 0.20%, silicon: 0.56%, manganese: 1.25%, chromium: 0.09%, aluminum: 0.012%, nickel: 0.01%, copper: 0.05% %, phosphorus: 0.009%, sulfur: 0.053%, vanadium: 0.08%, nitrogen: 0.0149%, lead: 0.001%, tin: 0.004%, arsenic: 0.002%, antimony: 0.003%, and the balance is iron.

[0088] The preparation method of the non-quenched and tempered steel of the present embodiment comprises the steps:

[0089] 1. EAF smelting

[0090] According to the above ingredients, the ingredients are sent to the electric furnace for smelting; during the smelting process, the proportion of molten iron entering the furnace is controlled to be ≥50%, and the proportion of scrap steel is ≤50%, so as to meet the requirements of copper, lead, tin, arsenic and antimony in the composition. Content requirements; in addition, control electric furnace tapping P≤0.015%, prohibiting slag during t...

PUM

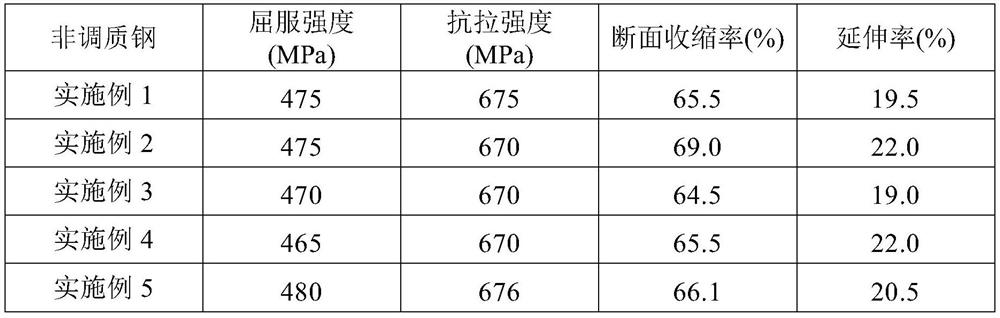

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com