A nanocomposite superabsorbent material and its preparation method

A superabsorbent material and nanocomposite technology, applied in the field of functional polymer materials, can solve problems such as application limitations, agglomeration and agglomeration, and performance impact of superabsorbent resins, and achieve uniform and stable particle size, fast absorption rate, and short drying time. shortened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

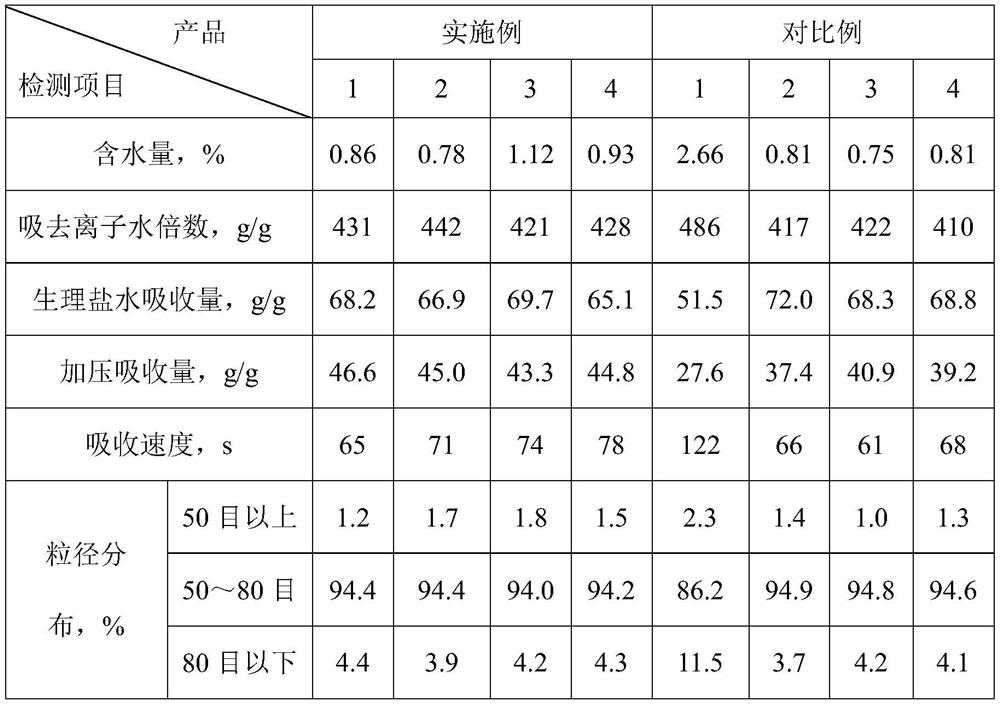

Examples

Embodiment 1

[0030] Embodiment 1 A kind of nanocomposite superabsorbent material

[0031] A method for preparing a nanocomposite superabsorbent material, comprising the following steps:

[0032] (1) Sodium hydroxide is dissolved in deionized water to obtain an alkali solution with a mass content of 55% of sodium hydroxide, and acrylic acid is added to the alkali solution under stirring to obtain a partially neutralized acrylate solution. The mixture of sodium hydroxide and acrylic acid is The amount ratio is 0.8; cool down to normal temperature (25±2°C), add acrylamide, crosslinking agent, initiator, and stir to obtain reaction solution A;

[0033] Among them, the addition of acrylamide is 5% of the mass of acrylic acid; the crosslinking agent is butanediol diacrylate, and the addition of the crosslinking agent is 0.05% of the mass of acrylic acid; the initiator is potassium persulfate, and the addition of the initiator is 0.2% of the mass of acrylic acid;

[0034] (2) Transfer the react...

Embodiment 2

[0038] Embodiment 2 A nanocomposite superabsorbent material

[0039] A method for preparing a nanocomposite superabsorbent material, comprising the following steps:

[0040] (1) Sodium hydroxide is dissolved in deionized water to obtain an alkali solution with a mass content of 55% of sodium hydroxide, and acrylic acid is added to the alkali solution under stirring to obtain a partially neutralized acrylate solution. The mixture of sodium hydroxide and acrylic acid is The ratio of the amount is 0.7; cool down to normal temperature, add acrylamide, cross-linking agent, initiator, stir evenly to obtain the reaction solution A;

[0041] Among them, the addition of acrylamide is 10% of the mass of acrylic acid; the addition of the crosslinking agent trimethylolpropane trimethacrylate is 0.2% of the mass of acrylic acid; the initiator is sodium persulfate, the initiator The addition amount is 0.3% of acrylic acid quality;

[0042] (2) Transfer the reaction solution A to a polytet...

Embodiment 3

[0046] Embodiment 3 A nanocomposite superabsorbent material

[0047] A method for preparing a nanocomposite superabsorbent material, comprising the following steps:

[0048] (1) Sodium hydroxide is dissolved in deionized water to obtain an alkali solution with a mass content of 55% of sodium hydroxide, and acrylic acid is added to the alkali solution under stirring to obtain a partially neutralized acrylate solution. The mixture of sodium hydroxide and acrylic acid is The amount ratio is 0.6; cool down to normal temperature, add acrylamide, crosslinking agent, initiator, stir evenly to obtain reaction solution A;

[0049] Among them, the addition of acrylamide is 7% of the mass of acrylic acid; the cross-linking agent is butanediol diacrylate, and the addition of the cross-linking agent is 0.05% of the mass of acrylic acid; the initiator is potassium persulfate, and the addition of the initiator is 0.05% of the mass of acrylic acid;

[0050] (2) Transfer the reaction solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com