Method and system for detecting safety of lifting iron ladles and steel ladles by crown block

A technology of safety detection and crane, which is applied in the directions of safety devices, transportation and packaging, and load suspension components, etc., which can solve problems such as poor mental state, unstable crane bag, and poor night vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the examples.

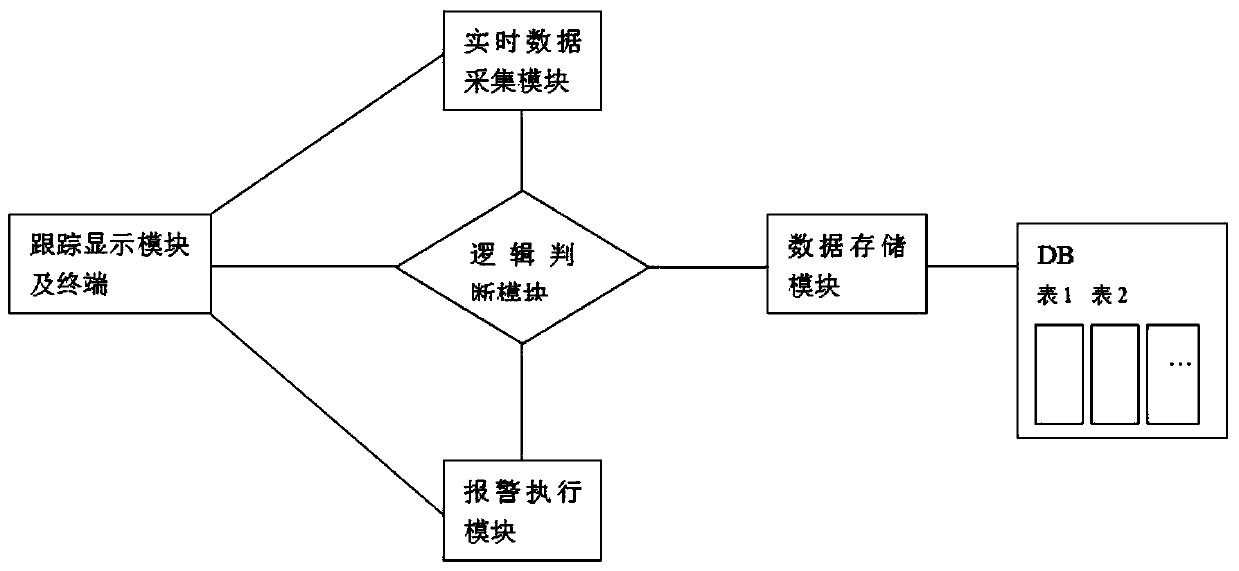

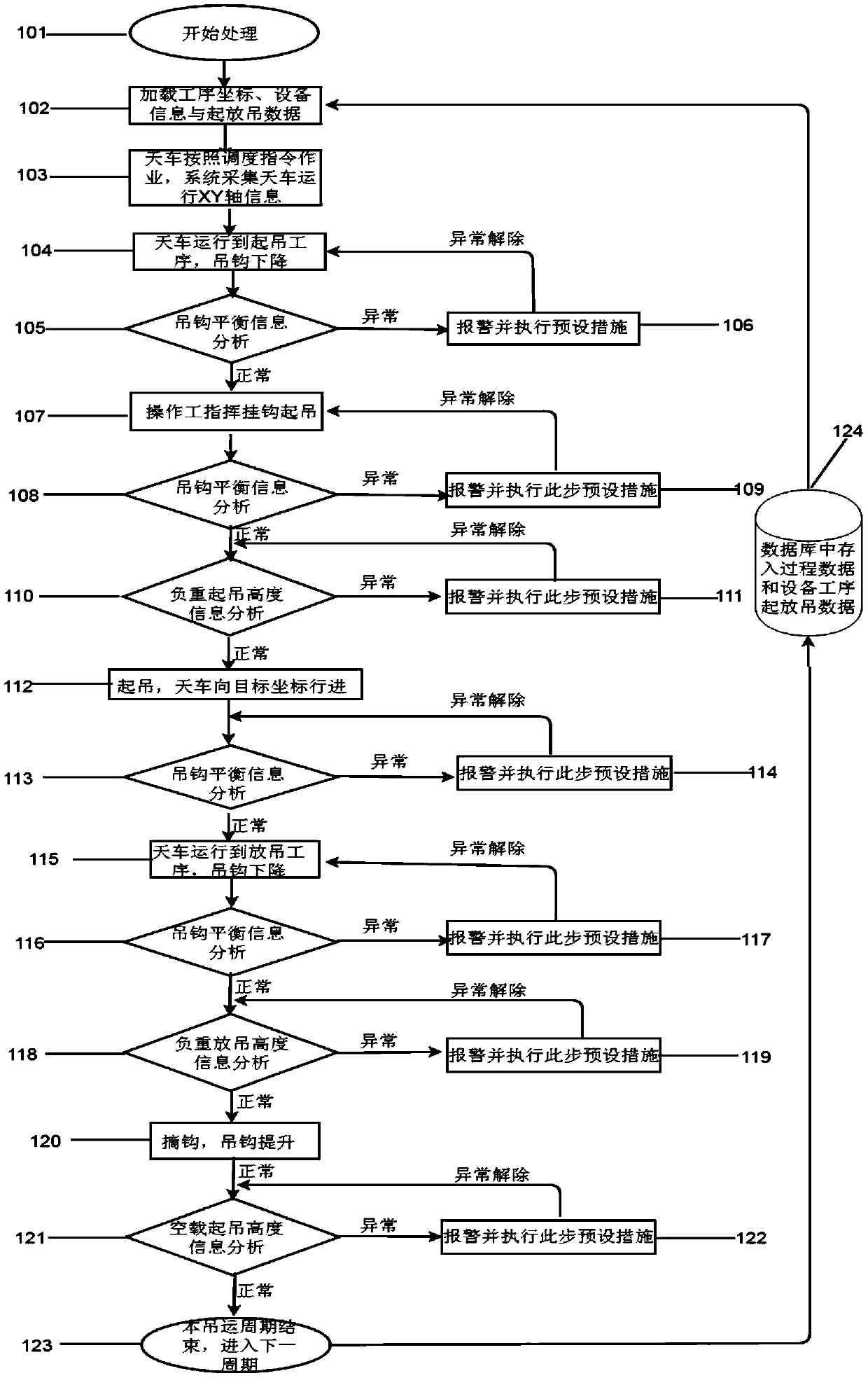

[0032] The invention discloses a safety detection method and system for hoisting and transporting iron and steel ladles by a crane, which is used for detecting whether there is a crane-winch system-wire rope-hanging beam hook-ladle trunnion-trolley-rail base system Abnormal deformation, check whether the hook and trunnion are lifted firmly in place, prevent one-sided hook and excessive shaking during lifting, thereby increasing the safety of iron ladle and steel ladle transfer operations. The method can not only be applied to the operation of hoisting and transporting iron ladles and steel ladles by the crane, but is also applicable to the operation of lifting and transporting other objects by the crane, thereby increasing the safety of lifting and transporting the iron ladles and steel ladles by the crane.

[0033] The detection method disclosed in the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com