Mining material detection circuit and device

A technology for material detection and mining, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as unsafe hidden dangers, miscellaneous staff, short circuits, etc., to achieve broadened working range, simple structure, and reduced energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

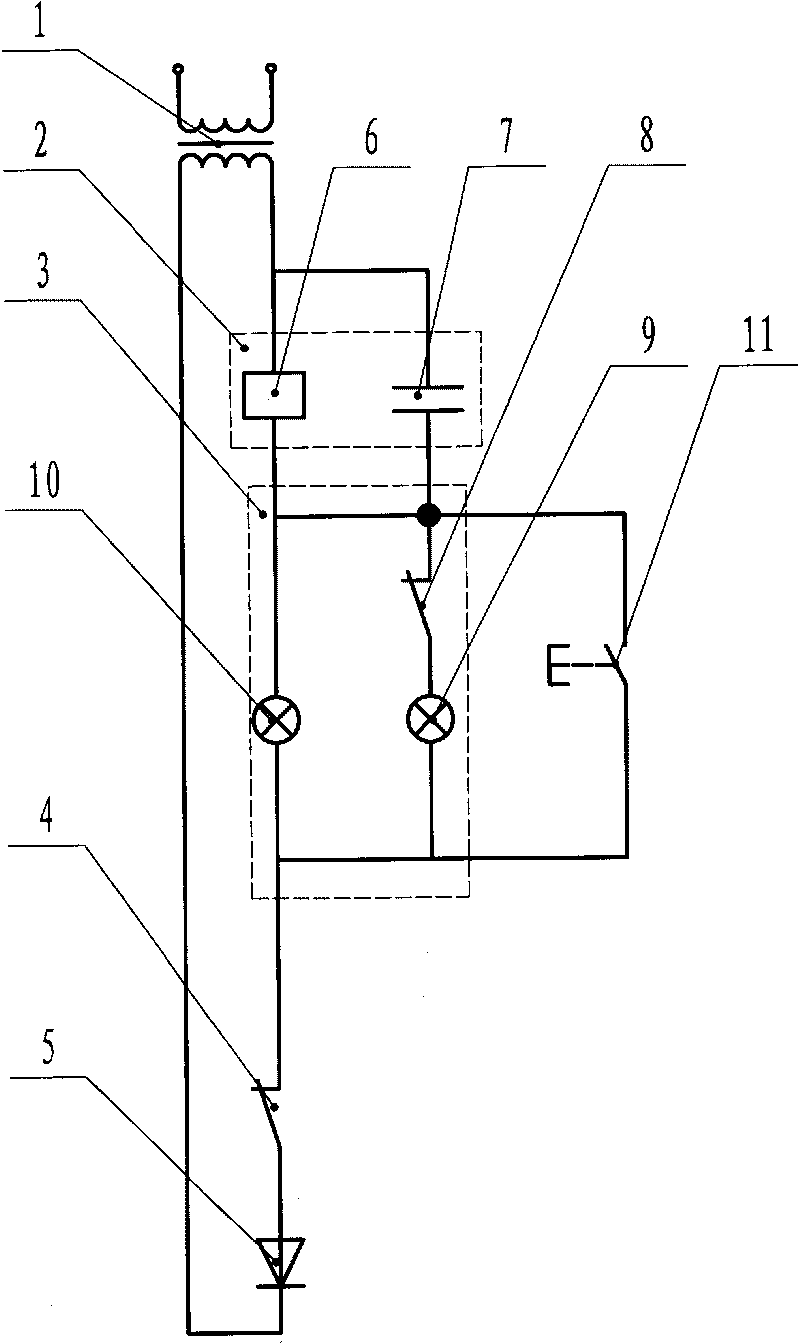

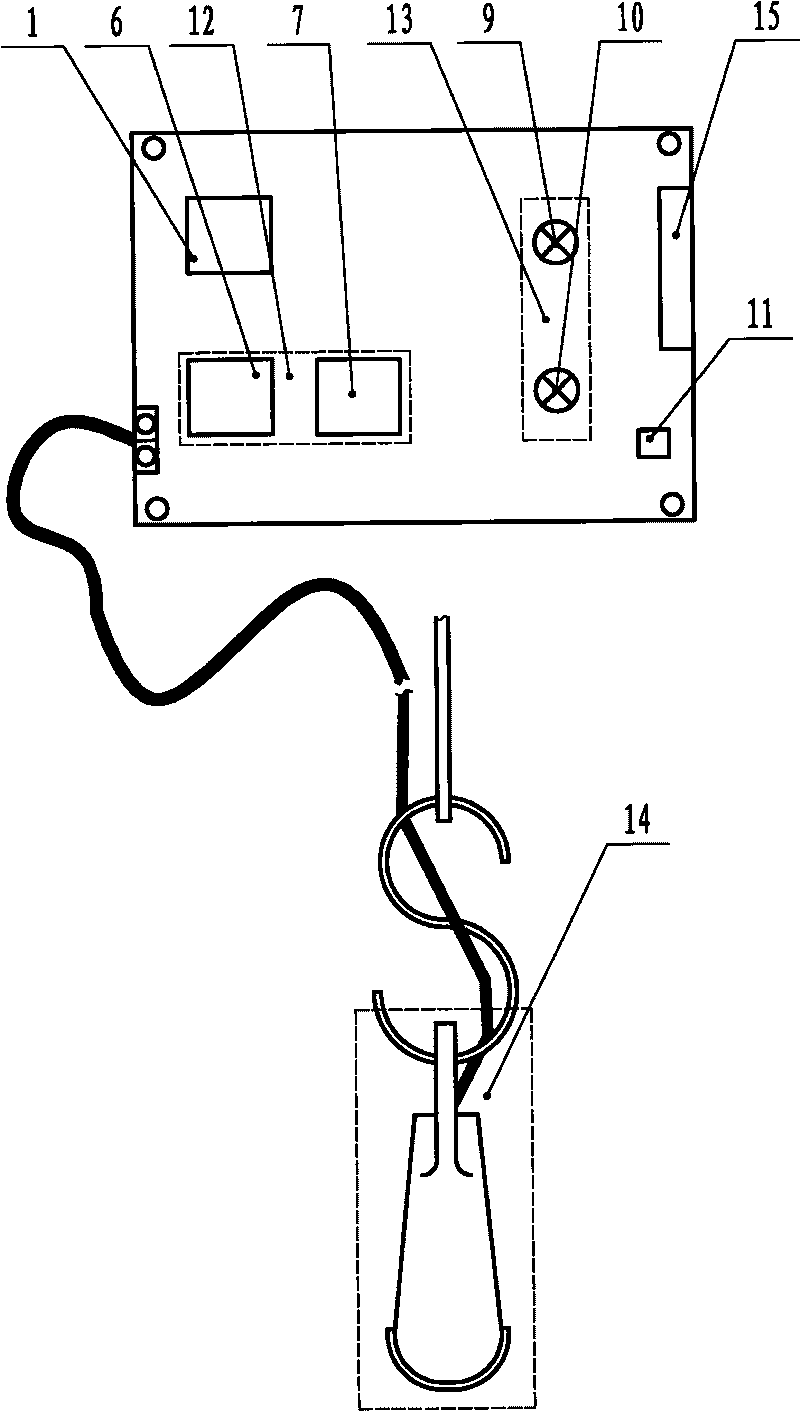

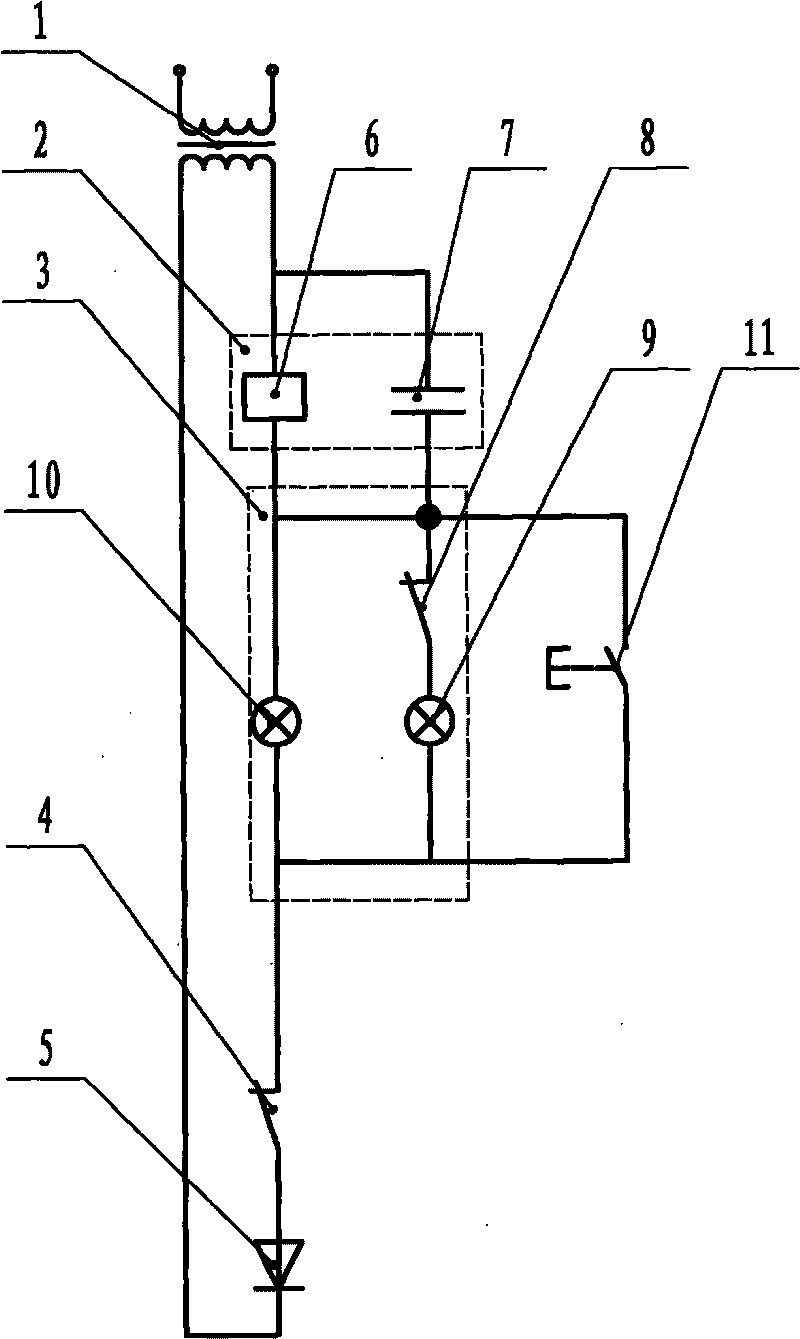

[0019] Such as figure 1 As shown, the mining material detection circuit includes: transformer 1, control circuit 2, indicator circuit 3, tilt switch 4 and diode 5, wherein the power supply is step-down through the transformer 1 and is sequentially connected with the control circuit 2, indicator circuit 3, and tilt switch 4 Connected with the diode 5, the control circuit 2 is composed of a DC relay 6 and a capacitor 7 connected in parallel, and the indicator circuit 3 is composed of two circuits connected in parallel, one of which is the normally closed contact 8 of the DC relay 6 and the second One indicator light 9 is connected in series, the other is composed of a second indicator light 10, and a reset circuit 11 is connected in parallel beside the indicator circuit 3. The reset circuit 11 is composed of a conventional reset switch, and the power supply is industrial voltage 380V or household power. 220V, both are sinusoidal AC voltages, which are reduced to a safe voltage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com