Accurate and automatic batching system for hard alloy powder

An automatic batching, cemented carbide technology, applied in the direction of solid materials, packaging, packaging items, etc., can solve the problems of inability to record data, unwillingness of new people to come in, low production efficiency and batching accuracy, etc., to improve product quality and save money. Human resources, the effect of improving the level of ingredient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

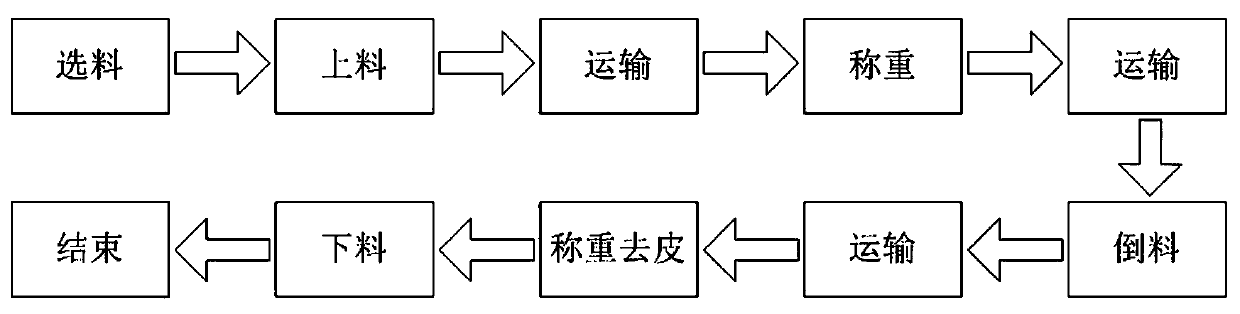

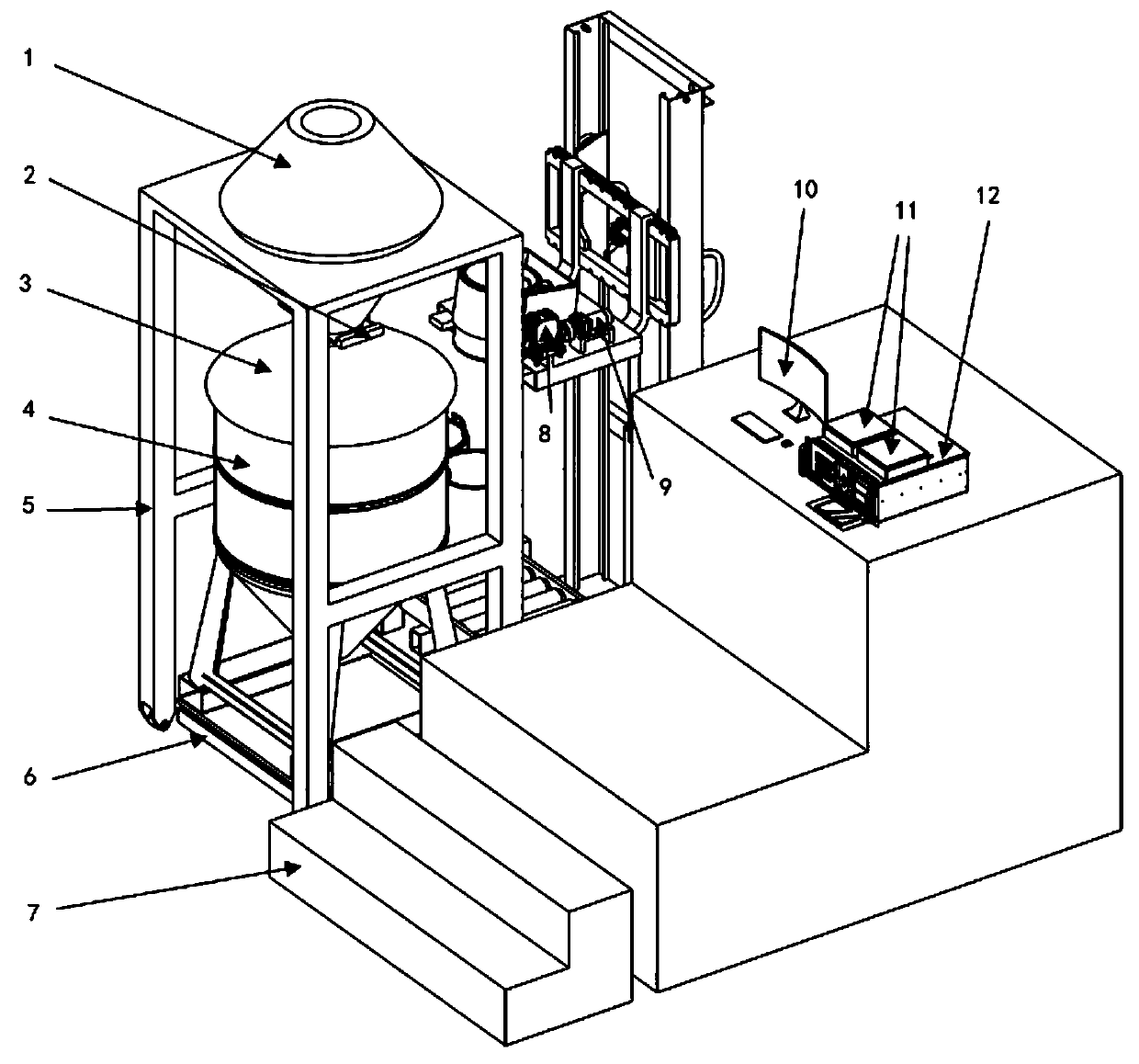

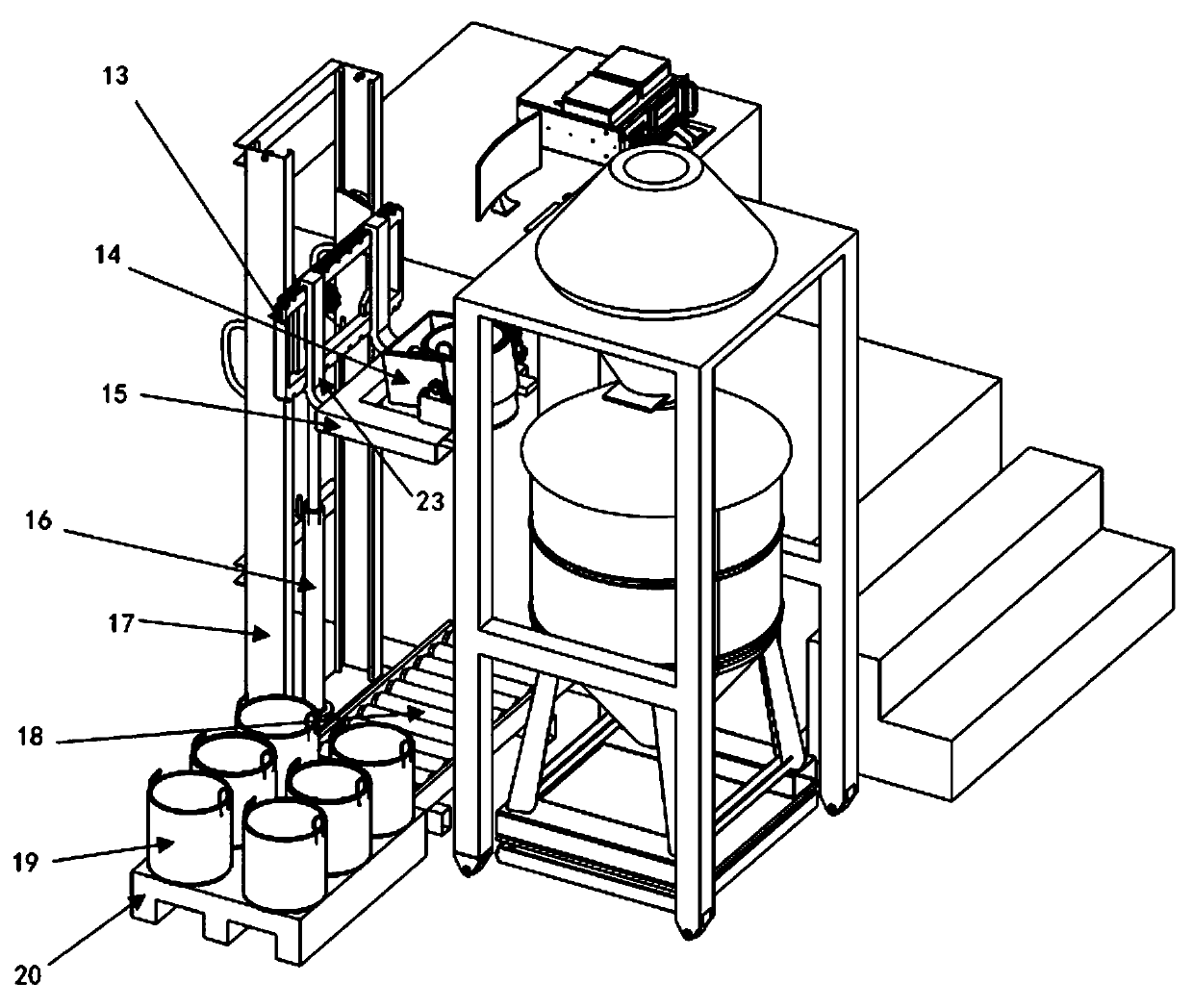

[0025] Such as Figure 1-3 As shown, an accurate automatic batching system for cemented carbide powder is composed of a mechanical part and a batching control part. Weighing and peeling, cutting to the end, the computer is used to supervise the whole process, and the intermediate data of the batching process is stored in the background database, combined with the production management system, the production data of the batching is analyzed, managed, counted and backed up. The ingredient control part is managed by VS2015 platform and SQL database (such as Figure 8 shown).

[0026] The mechanical part is mainly composed of a lifting mechanism, a feeding mechanism, a guide rail 18, a weighing platform, a batching bucket, and weighing instruments (including platform scales, balances, and special weighing trays), etc. The lifting mechanism is connected with the feeding mechanism, and the guide rail It is arranged at the lower end of the lifting mechanism, and the batching bucket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com