A segmented division design method for a G4 type rolling ship

A design method and ro-ro ship technology, applied in ship parts, ship construction, ships, etc., can solve the problem of increasing the difficulty of the installation accuracy control of the embedded box feet of the ro-ro armor plate container, the unfavorable control of the ship construction cycle and construction quality, and the collection of rolling. Due to the complex structure and form of the stern of the ship's engine room, it can achieve the effect of reducing the number of subsections, reducing the workload of loading, and reducing the difficulty of precision control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments, but the protection scope of the present invention should not be limited by this.

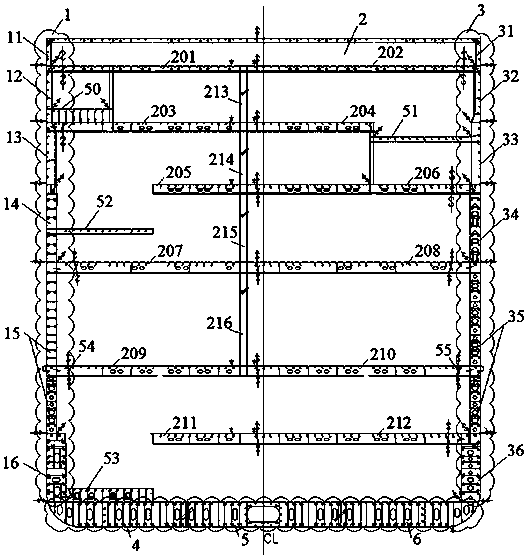

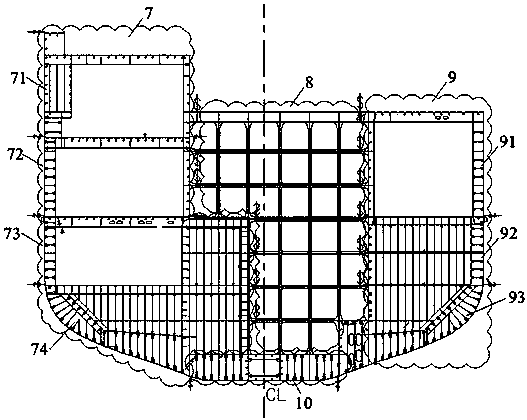

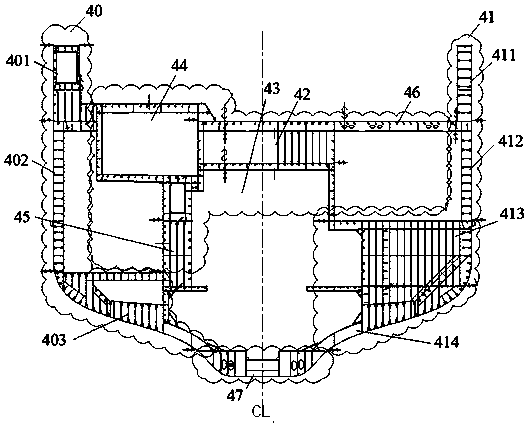

[0027] Such as figure 1 , figure 2 and image 3 As shown, the segmental division design method of the G4 type ro-ro ship in the present embodiment is characterized in that the method comprises the following steps:

[0028]The first step, the segmentation form of the ro-ro area in the cargo hold: the ro-ro area is divided into left, middle and right sides, the port side segment area 1, the middle ro-ro deck area 2 and the starboard side segment area 3, and the port side segment area 1 From top to bottom, it includes the first layer of port side segment 11, the second layer of port side segment 12, the third layer of port side segment 13, the fourth layer of port side segment 14, the fifth layer of port side segment 15 and the sixth layer of port side Subsection 16: The middle ro-ro deck area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com