Torque signal compensation circuit of four-wheel driven system of electric automobile

A torque signal and four-wheel drive technology, applied in the circuit field, can solve the problems of frequency hopping, large signal error range, etc., and achieve the effect of preventing the potential from being too large or too small, reducing the signal error, and solving the problem of signal attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

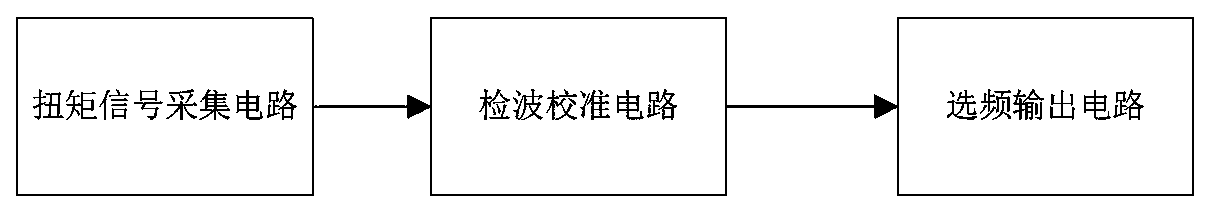

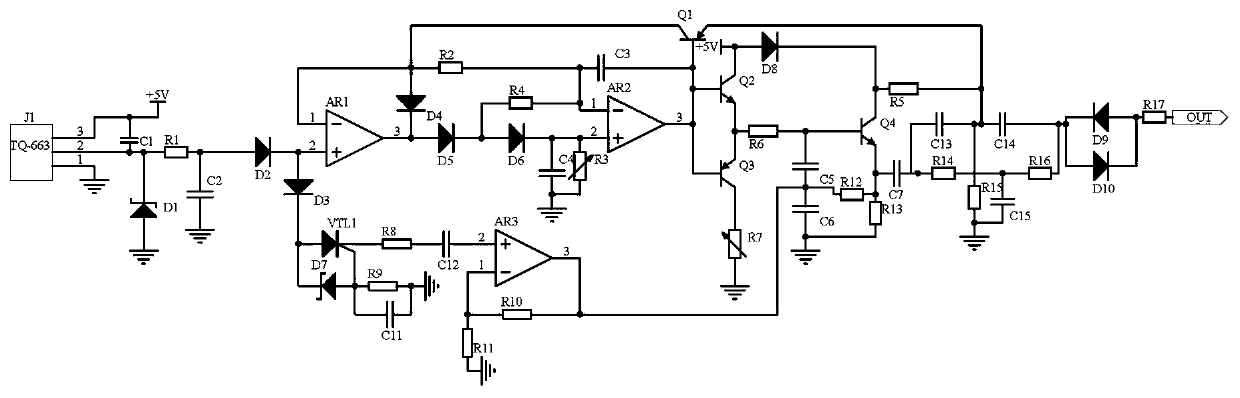

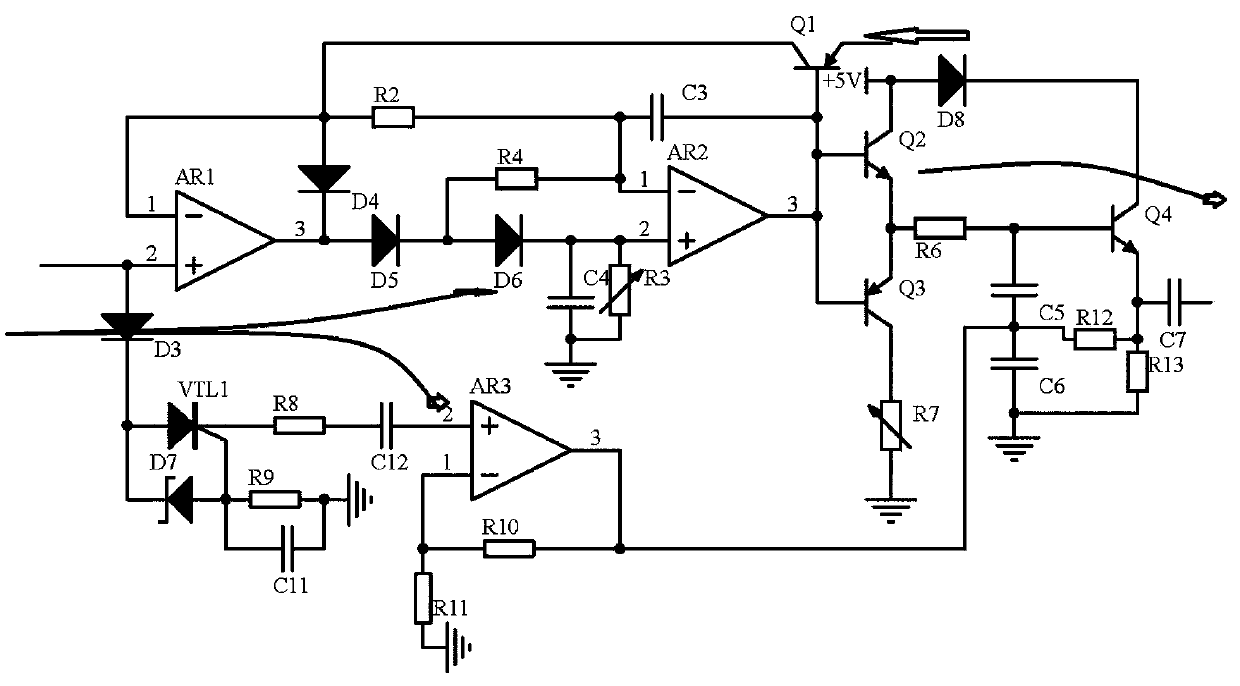

[0014] Embodiment 1, the torque signal compensation circuit of the four-wheel drive system of an electric vehicle includes a torque signal acquisition circuit, a detection calibration circuit and a frequency selection output circuit, and the torque signal acquisition circuit uses a model TQ-663 torque sensor J1 to collect the Torque signal when the four-wheel drive system is working, the detection and calibration circuit is divided into two ways to receive the output signal of the torque signal acquisition circuit, and one way uses the operational amplifier AR1, operational amplifier AR2, variable resistor R3, and capacitor C4 to form a peak detection circuit pair Signal detection, at the same time use the transistor Q2, transistor Q3 to form a push-pull circuit to reduce the conduction loss of the signal, and use the transistor Q4, capacitor C5, capacitor C6 to form a frequency modulation circuit to modulate the signal frequency, and the second circuit uses the thyristor VTL1 a...

Embodiment 2

[0017]Embodiment 2, on the basis of Embodiment 1, the frequency selection output circuit uses resistors R14~resistor R16 and capacitor C13-capacitor C15 to form a double T frequency selection circuit to filter out a signal of a single frequency, keeping the same frequency as the original signal At the same time, the switch circuit composed of diode D9 and diode D10 is used to output the signal limit to prevent the compensation signal potential from being too large or too small, that is, the compensation signal of the torque signal in the signal transmission module of the four-wheel drive system of the electric vehicle The signal compensation method solves the signal attenuation problem and reduces the signal error. One end of the capacitor C13 is connected to the other end of the capacitor C7 and one end of the resistor R14, and the other end of the capacitor C13 is connected to the emitter of the transistor Q1 and one end of the capacitor C14 and the resistor R15. The other en...

Embodiment 3

[0018] Embodiment three, on the basis of embodiment one, the torque signal acquisition circuit adopts the model TQ-663 torque sensor J1 to collect the torque signal when the four-wheel drive system of the electric vehicle is working, the regulator tube D1 stabilizes the voltage, and the torque sensor J1 The power supply terminal is connected to the power supply +5V and one end of the capacitor C1, the ground terminal of the torque sensor J1 is grounded, the output terminal of the torque sensor J1 is connected to the other end of the capacitor C1, one end of the resistor R1 and the negative pole of the voltage regulator tube D1, and the voltage regulator tube D1 The positive terminal of the resistor R1 is connected to one terminal of the capacitor C2, the positive terminal of the diode D2, the other terminal of the capacitor C2 is grounded, and the negative terminal of the diode D2 is connected to the non-inverting input terminal of the operational amplifier AR1.

[0019] When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com