Polishing workstation and polishing method thereof

A workstation and polishing machine technology, applied in grinding/polishing equipment, surface polishing machine tools, manufacturing tools, etc., can solve the problems of large manpower, inability to guarantee the consistency of polishing trajectory, and high process requirements, so as to ensure constant force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

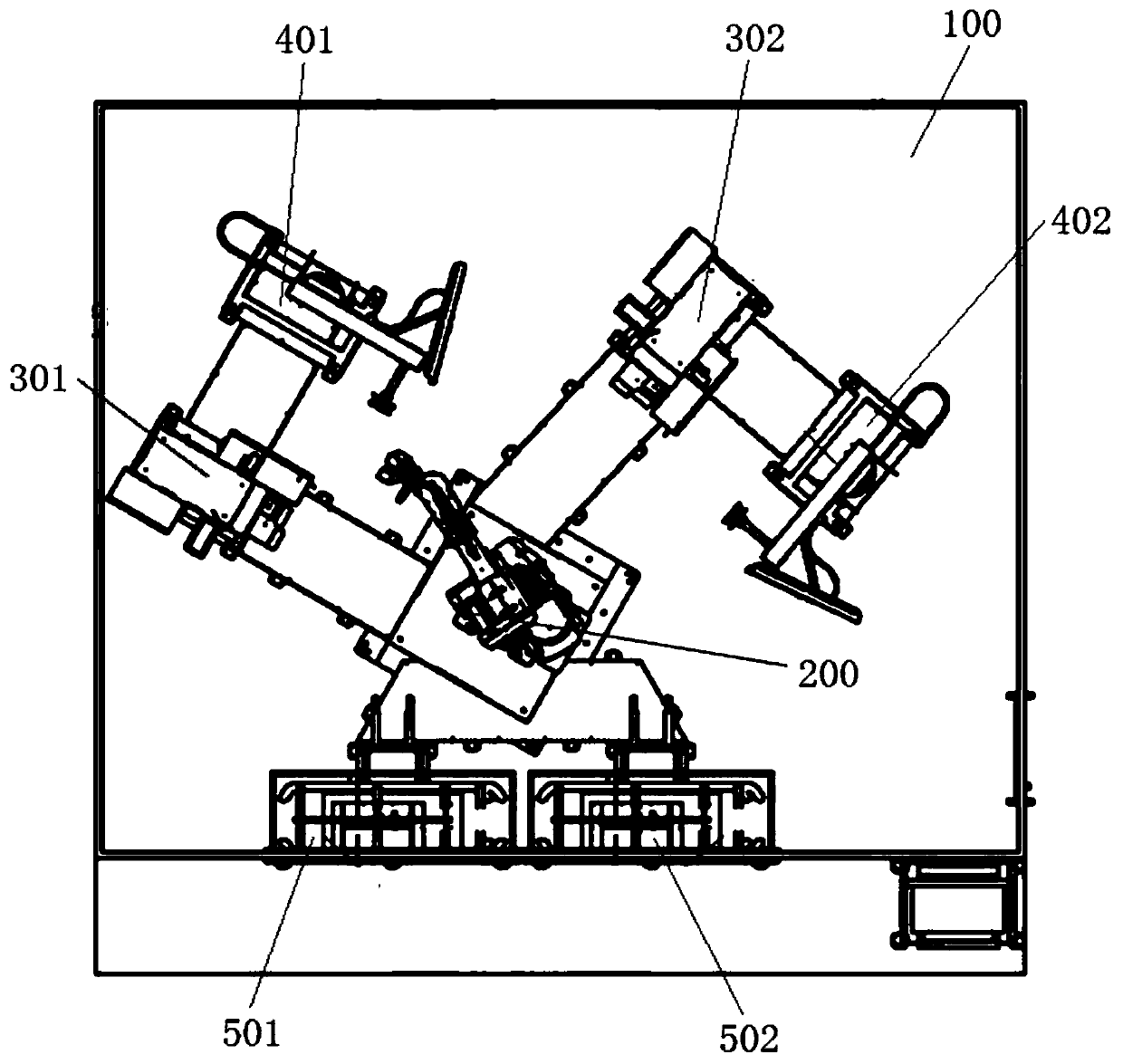

[0040] see figure 1, an embodiment of the present invention, a polishing workstation, including a processing chamber 100, two large polishing machines, two small polishing machines, a robot 200 and a two-station feeding slide.

[0041] The two large polishing machines include the left large polishing machine 301 and the right large polishing machine 302, the two small polishing machines include the left small polishing machine 401 and the right small polishing machine 402, and the two-station feeding slide includes the left upper Material sliding table 501 and right feeding sliding table 502; two large polishing machines, two small polishing machines and a robot are respectively arranged in the processing room 100; the robot 200 is located in the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com